Facing the balcony with plastic panels: a simple task

Plastic panels for many years remain the most affordable finishing material. It is such material that is best suited for decorating an unheated loggia.

So we will tell you which plastic panels for facing the balcony is better to choose, and how to install them yourself.

The content of the article

Select panels

The affordable price is not the only criterion for the choice of plastic by the consumer, there are other qualities that are no less valuable: resistance to moisture and ultraviolet, a sufficiently high melting point, and ease of installation. In addition to the advantages that we have already mentioned, polymer panels have some more properties that deserve attention.

So:

- Polychlorovinide is practically not afraid of chemical and abrasive effects, which allows you to use any household chemicals in its care. Although, such tools may not be needed, because the surface of the plastic is dense and smooth, and does not have pores that can clog up with dirt.

- A thorough cleaning of such a coating may be necessary only in the kitchen, where soot and particles of fat settle on the walls and ceilings. Apart from dust, nothing threatens the balcony.

And if you take into account the very diverse range of colors, reliefs and finishes, it becomes clear that facing of balconies PVC panels can be not just diverse, but even original.

- Plus, a high-quality plastic coating can serve for more than a dozen years. The main thing is not to look for what is cheaper, but to approach the choice responsibly, and competently.

But to draw conclusions from the category: once expensive, then high-quality - also not worth it. Remember the "golden" middle. - There are many ways to determine what quality Pvc panel in front of you. In general, the main disadvantage of this material is its fragility.

Each of you probably saw characteristic breaks in the rooms lined with plastic. It happens that one wrong move, a push into the wall, for example, with a chair, and the panel is damaged. - Fragility depends on the amount of chalk in the composition of polychlorovinide: the more it is, the more fragile the product will be. Some unscrupulous manufacturers, in the pursuit of profit, deliberately go for such a violation of technology. Much depends on the thickness of the panel.

- You can determine the quality of the panel for facing balconies by pressing a finger on its surface. If a trace remains on it, you can be sure that this material is of the lowest quality.

The surface of a good panel should be resilient enough not to succumb to such a slight force.

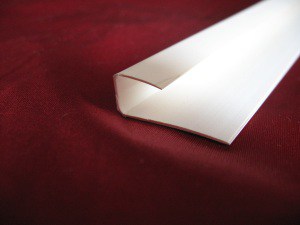

- Next, check the strength of the panel by clicking on the end cut. The panel structure has internal stiffening ribs. So, if, when pressed, they broke, or simply formed, this indicates a low quality product.

Plastic panel high quality will spring when you click on the cut. And yet: the wider the panel, the less durable it can be.

Therefore, wide panels are good only for covering the ceiling. For walls, choose narrower options.

Getting to work

Lining balconies with PVC panels is most often done on a wooden crate. Therefore, in addition to the panels themselves, you will need 15 * 30 mm slats.

This is if the walls are relatively even - the more bumps, the thicker the lathing elements should be.In addition, if warming is performed, not a rail is used, but a bar 30 * 30 mm.

Crate Installation

The frame is mounted immediately on all surfaces that are planned to be sheathed. The standard step between the elements of the crate is 60 cm.

But it can be reduced, especially in those places that may be further subjected to mechanical stress.

Usually this is the area adjacent to the door and balcony frame:

- Fix the rail to the base with dowels, under which, according to preliminary marking, drill holes with a puncher. The distance between them should not exceed one meter.

- Reiki should be in one plane, and their position is adjusted, if necessary, by putting pieces of the same rail or plywood at the right points. In the photo below, you can see how the belts are adjusted using the fitted blocks.

- Of course, the wooden crate cannot be perfectly smooth, since the rails and bars themselves often differ in curvature. But if the difference does not exceed half a centimeter, the expansion of the belts will be invisible.

- When mounting the crate belts, do not fix them tightly, but first just make money. So it will be easier to adjust them.

To do this, cut the panel to the height of the loggia and place it on the frame in the position in which it will be installed. - By attaching a building level to the panel surface, you can see the position of which grating belts should be corrected. If there is a gap between the bar and the lining, a piece of plywood must be placed under this element.

After this, the screws can be fixed all the way.

Despite the fact that our instructions are given for cladding on a wooden crate, the installation of PVC panels can be done on a frame made of aluminum profile. But in practice this rarely happens, since, in this case, the metal frame may be more expensive than the lining itself.

We hung panels

To start facing, in the left corner you need to set the start profile. To fix it, as well as to fasten the PVC panels themselves, you can use screws with a press washer, a construction stapler, or small nails.

- As you can see, the start profile has a U-shape. The first panel is inserted into its cavity and fixed.

If you are engaged in cladding for the first time, watch the video in advance - this will help you better understand what and how to do it right. - Each panel has a ridge on one side and a groove on the other. This type of connection is called - tongue-and-groove.

When facing the walls in this way, you should not have any complications. - In the process of sheathing, the panels have to be cut not only from the end, but also in the longitudinal direction. It is most convenient to do this with an electric jigsaw, especially if you have to cut curved lines. For example, if there are arched openings.

- But, you can use a conventional hacksaw, and even a clerical knife. Although, using it to achieve cutting accuracy is much more difficult.

- The last panel in the row is cut in width, put on the starting profile on the cut, and inserted into its rightful place so that the lining of the village is tight. If necessary, the dismantling begins in the reverse order, that is, from the finish panel.

- Facing a solid surface is not particularly difficult, but there are also door and window slopeswhich also need to be beautifully faced. In this case, the panel almost always has to make recesses under the opening, that is, cut both in width and length.

- Just keep in mind that the cut should be as even as possible so that it can overlap with an external plastic corner. Mount the corners on the glue “liquid nails” or “Moment-installation”, fixing their position with masking tape until completely dry.

- The slopes themselves are set like this. All the same starting profile is screwed around the perimeter of the window or door with 16 mm screws.

Cut the plastic to the size of the slope, and insert it into the starting profile, fixing it to the wooden crate of the wall. - Plastic ceiling lining is no different from wall cladding, and even simpler. If there was an inaccurate cut, you can not worry, because the joints of the surfaces of the ceiling and walls are closed with a ceiling plinth.

PVC panels are perfectly combined with other types of finishes: plaster, decorative brickwork, tiled cladding. Sheathing is often done only on the parapet and side walls.

It is these places that require insulation, and the frame for the casing is very convenient for the installation of insulation. If you are interested in how to do this correctly, read the articles on this topic on our website.

Plastic panels are the simplest type of facing a balcony, or loggia. They are installed very quickly. In addition, in the future, plastic does not require any maintenance.