Window cladding inside and out

Such works as the installation of skirting boards and ceiling cornices, the decoration of door and window slopes on the part of the premises and on the facade are considered a real trifle compared to general construction and repair measures. But it is they who put the final point, create a complete look of the interior.

But the matter is not only in beauty. High-quality slopes strengthen the opening, protect it from destruction, play a large role in the thermal insulation of the building.

The content of the article

Window Cladding Materials

After the installation of the double-glazed window, slopes are installed, the material for the manufacture of which is selected taking into account such parameters as climatic characteristics of the region, the purpose of the room, the requirements for the appearance and style of decoration, practicality, price, etc.

The main selection criterion is which side of the building - internal or external - is facing. It is clear that not all materials used in rooms with stable temperature and humidity conditions are suitable for window decoration on the facade of the house.

For interior decoration

In principle, in rooms with normal humidity and constant temperature, slopes can be made of any materials. Here, the main criteria are appearance, compatibility with the interior, practicality in care.

Most often, the inner cladding of windows is made of the following materials:

- Stucco followed by painting;

- Drywall, plywood, chipboard and other sheet materials, which also serve as the basis for subsequent finishing;

- Wood;

- Plastic sandwich panels;

- Ceramic tile;

- Artificial stone for window cladding, etc.

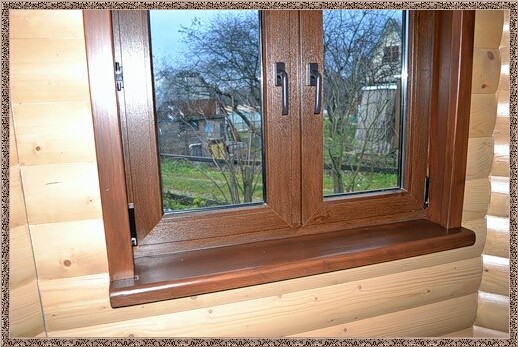

It also matters what the double-glazed windows themselves are made of. If they are wooden, plastic slopes can only spoil the appearance of the window, reduce the cost of it. But the plastic window lining may well be made of sandwich panels or PVC panels.

The same materials along with smooth tiles or ceramic tiles (seeTiling windows - rules for finishing corners and slopes) - the most practical for finishing openings in humid rooms or those in which you often have to do wet cleaning and disinfection - in kitchens, bathrooms, hospital wards, child care facilities, etc.

For exterior decoration

Exterior window lining reduces the above list of materials by several positions. This primarily relates to drywall and other sheet materials based on wood waste, which are completely unsuitable for outdoor use.

Under the influence of high humidity, direct exposure to snow and rain, sharp temperature fluctuations, they are deformed and destroyed. Not suitable for exterior decoration and decorative tiles for brick or stone on the basis of gypsum - it is also very afraid of moisture.

On the other hand, this list can be expanded to include the following materials:

- Metal. Slopes are made of galvanized steel with a color polymer coating;

- Facing brick or brick tile;

- Siding. Or rather, special additional elements designed for finishing openings on facades sheathed with this material.

Note.When choosing a window cladding option from the outside, what the building is made of or what the building is made of is of great importance. It is hardly appropriate to glue artificial stone on them if the facade is wooden. But the metal slopes look great in any combination, subject to proper color selection.

In general, there are many nuances in the selection of suitable materials. For example, if there are no problems with rectilinear openings during installation of any of them, then the lining of round windows or openings with arched vaults imposes certain restrictions.

And the choice here is not so great - it is either plaster, or finishes with small pieces, or the use of flexible materials. For example, drywall, which when wetted, you can give the desired shape. After drying, all its operational characteristics are returned to the material.

For window sills

The window sill lining can be made of the same material as the slopes. But it usually has more stringent requirements for strength, resistance to damage and moisture and other parameters. Therefore, it is not recommended to make it from drywall, ordinary plastic, to plaster it.

Today in the construction market there are a lot of offers of ready-made window sills, which only need to be adjusted in length and width. They are made of specially treated wood, durable plastic, moisture-resistant MDF and chipboard with a decorative plastic or laminated coating.

Cast window sills made of artificial stone are becoming increasingly popular. They are made individually after taking measurements and choosing the desired shape, and are installed by the manufacturer. Pleasure is not cheap, but, as they say, for centuries.

Unfortunately, this option is not affordable for everyone, in addition, if you want to change the interior, you will just feel sorry for a lot of money. But there is another way to design the lower part of the window in an original way by installing a figuredly sawn sheet of durable moisture-resistant material and decorating it with porcelain stoneware or mosaic.

Thus, the lined window sills look great, are not afraid of moisture and heavy loads, are scratch resistant, and are easy to clean. And if desired, the tile during the next repair can be replaced.

The window sill is installed indoors and often performs additional functions - countertops, coasters for home plants, shelves for small household appliances in the kitchen.

And the outside window cladding involves mounting along the lower edge of the tide frame - an inclined structural element designed to drain the water flowing from the window and protect the installation joint from moisture. The most common material for the manufacture of castings is galvanized and polymer-painted metal.

In a word, the decorative cladding of windows today can be very diverse due to the availability of a huge amount of traditional and modern materials. Inspiration is also caused by the fact that many of them are easy to mount with their own hands, achieving not only an aesthetic appearance of openings, but also increasing their operational properties.

Framing openings - examples of installation of slopes of different materials

If desired, the work on the decoration of slopes can be handled independently, especially when it comes to the installation of sheet materials. Some difficulty in the absence of practice is caused by plastering, tile sticker and other “wet” processes.

If the finish is carried out with specially designed elements for this, then a complete installation instruction is usually attached to the kit, following which the work can be handled without special knowledge and preparation. For example, if you do not know how to clad windows with siding, ask the seller for an installation scheme or look for recommendations on the website of a particular manufacturer.

Below we will talk about how to make the window lining yourself using the most common materials - plaster, drywall and plastic sandwich panels.

Slope plastering

This finish option is attractive primarily for its low cost and durability. For work, only a dry building mix diluted with water will be required.

So:

- Work begins with rough leveling of the surface by cutting off the influx of concrete in the corners, after which it is cleaned of dirt and dust;

- The gaps between the wall and the double-glazed window are filled with mounting foam or tow soaked in a plaster solution. At the same time, a gap should be left around the perimeter of the window box, which will be filled with the solution;

- When these materials dry, you can go directly to the plaster;

Note. Before making the window cladding, it is necessary to plaster and align the wall around it.

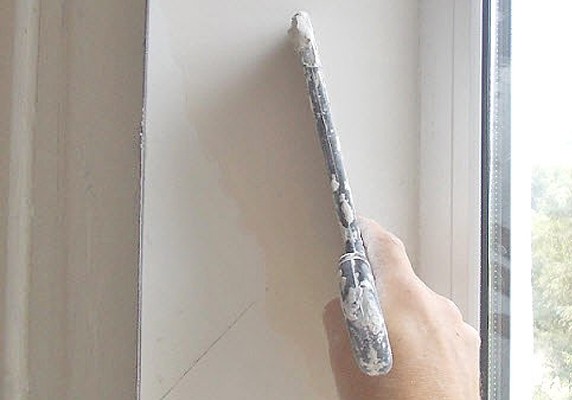

- The plaster begins by filling with a solution of the gap around the box. When it dries a little, the mixture is applied from bottom to top on the entire plane of the slope and leveled with a grater;

- If for leveling it is necessary to apply a thick layer of plaster, the work is performed in several stages, at a time applying a layer of not more than 5-7 mm and allowing it to dry;

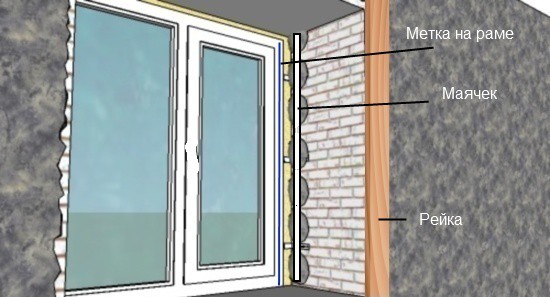

- It is desirable that the slopes are not perpendicular to the glazing plane, but slightly turned outward for better light penetration. Pivot angles on both sides must match.

In order not to make a mistake and facilitate their work, beacons are installed along the frame, and a wooden rail is temporarily mounted on the wall, controlling their verticality by a plumb line. Their faces will be reference points for alignment;

- In the same way, the upper slope is finished, fixing the beacon and rail horizontally with a level check;

- After the solution has dried, the slats are removed and the angle between the wall and the slope is removed;

- The final stage is surface grouting with finishing putty. Then the slopes can be painted.

In this way, both interior and exterior decoration is performed. But for external slopes it is better to take a special frost-resistant plaster, more resistant to the difficult climatic features of our country.

Installation of plastic slopes

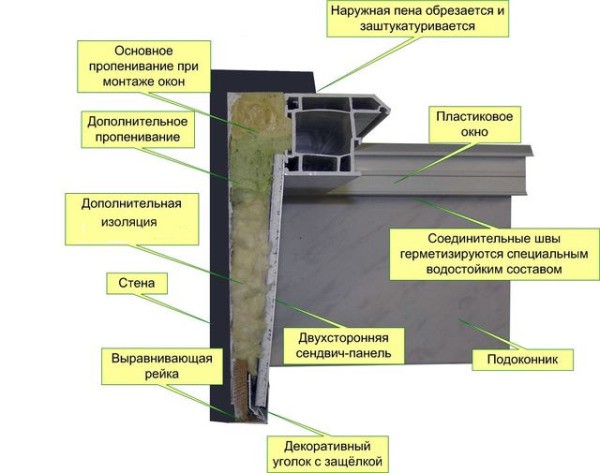

Most often people ask a question - how to make sandwich paneling for windows? This is a material in which foamed polystyrene is located between the two outer layers of plastic - an excellent heat-insulating material that protects the window opening from moisture and increases its sound-proofing characteristics.

The main advantage of plastic sandwich panels, in addition to those already indicated, is the finished appearance - after the installation is complete, the slopes do not need additional decoration. And the use of special profiles facilitates installation and allows you to make joints as accurately as possible.

As a rule, such slopes are installed when the glass is replaced by the installers themselves, but this work is paid separately. You can save by doing it yourself.

To do this, just watch the video, study the diagram below and follow our recommendations.

Work sequence:

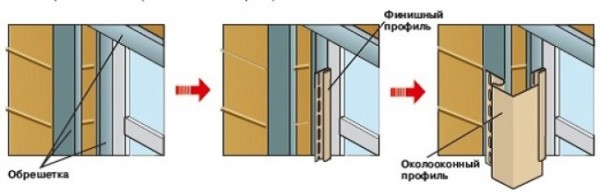

- After measurements, strips of the required height and width are cut out of the plate;

- The inner edge of the strip is wound behind the window box, after which the space between the wall and the future slope is filled with foam. When expanding, it will firmly press the panel against the window unit;

- A leveling rail is mounted on the outer part of the opening, which determines the angle of rotation of the slope;

- The panel is glued to the slope on liquid nails and latched onto the rail using a special profile.Or, if there is a large gap between the panel and the slope wall, it is filled with insulating material;

- The joint between the wall and the sandwich panel is closed with a decorative plastic corner, and the joints between adjacent panels are filled with a color-matched sealant.

Plasterboard slopes

For the manufacture of slopes, it is best to use moisture-proof drywall, resistant to natural moisture arising from condensation on the windows. If you took the usual, it is advisable to cover it several times with a primer.

Facing window openings with drywall differs little from the installation of plastic panels:

- The main difference is the installation of an L-shaped plastic profile around the frame perimeter, into which the drywall strips are inserted with their inner edge. Before this, an acrylic sealant is applied to the profile;

- The distance between the wall and the strip of drywall is laid with a heater;

- A layer of glue is applied to a narrow section of the wall closer to the outer edge and the outer edge of the material is pressed with a level to achieve its vertical position;

- After installing all the elements, the seams between them, as well as joints with the wall, are putty in accordance with the rules adopted for working with drywall;

- The final stage - finishing putty and painting.

As you can see, everything is quite simple. The main thing is accurate measurements and constant level control. Vertical for side slopes and horizontal for upper slopes.

Conclusion

It is the small details that make it possible to judge the quality of the repair, and it is they that create the finished look of the interior. Knowing how the material is selected and how the plastic windows are faced, you will avoid many mistakes and save time and money.

Even if you don’t start doing it yourself, competent control of the performers often helps to timely detect the marriage and non-compliance with the technology, which later can lead to unpleasant consequences and additional costs.

Outside you can’t do it yourself. High - you can’t get the stairs, and if you do it from the apartment, then it’s inconvenient.

The plaster seems to me not modern, and the plastic trim is too artificial. Here is drywall - a sweet deal. And on it you can already put any coating. I liked the option with a mosaic, I’ll take a note.