Facing staircases: types of materials

Facing steps with porcelain stoneware is not only distinguished by its originality, since it is possible to design a staircase in different ways due to the large selection of this type of material, but also by its durability.

The content of the article

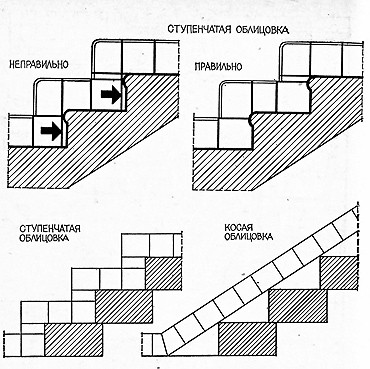

Methods for facing staircases

At the moment, in the design of staircases you can find:

- Porcelain tile (seeFacing stairs with granite: installation and design).

- Granite.

- Marble.

Advantageous characteristics:

- In terms of their properties and technical indicators, these materials have a certain similarity, but as for the external design, natural stones look more elegant.

- Porcelain tile on its surface may have imitations of natural agglomerate, and in its strength it will be slightly different (natural stone is much stronger than porcelain tile).

- Only when choosing a material it is worth considering that the price of natural finishing materials is much higher.

- For example, lining steps with granite slabs will look better than lining them with porcelain stoneware. But here it all depends on the design of the room and on financial capabilities.

Tip. Before giving preference to one or another type of material, it is necessary to take into account the principle of the staircase design and from what exactly the steps are made.

Types of stairs and materials for the manufacture of steps

There are several options for staircase construction:

- Wooden staircase.

- Metal.

- Concrete.

Note. From what material the stairs are made of, their decoration does not depend. You can use any design, only the methods of installation of the finish will be different.

There are stairs in their form:

- Direct.

- Screw.

- One-flight (with one flight of stairs).

- Two-flight (with two flights of stairs) and so on.

Tip. It is best to opt for a straight staircase with several flights than a screw structure to avoid possible injuries.

Step decoration the spiral staircase is also characterized by some knowledge in this area. The material used in the work will need to be trimmed and give it a certain triangular shape.

This is due to the fact that the steps of this design are indirect, but triangular and not with even angles.

Which stairs are the easiest to fix

The quality and method of installation of the finish depends directly on the material of which the staircase is made.

So:

- Wooden staircase structures, as a rule, do not need additional finishing, as they have wooden steps that are simply sanded and varnished.

- Porcelain or granite, marble can also be attached to them (seeMarble staircase lining: luxury and practicality) Only here is a special instruction used.

It prescribes not only the installation technology, but also the use of certain means.

Tip. To install the finish on a wooden staircase, it is best to use special glue.

- In this case, it is not worth grinding the surface of the marches. Facing steps with granite or any other similar material is able to hide all irregularities and surface defects.

- Concrete and metal steps mostly need finishing. They do not have an attractive appearance.

There are no restrictions on the use of material.

Tip. Since metal steps are made according to the principle of the box, it is imperative to make a small concrete pour on the metal sheets of the steps themselves.

- The same work is carried out on metal steps in the form of a "grid". Thus, the surface of the entire flight of stairs will be flat.

- Concrete staircases already initially assume a flat surface. On them, facing with granite steps or other material is performed quite quickly and simply.

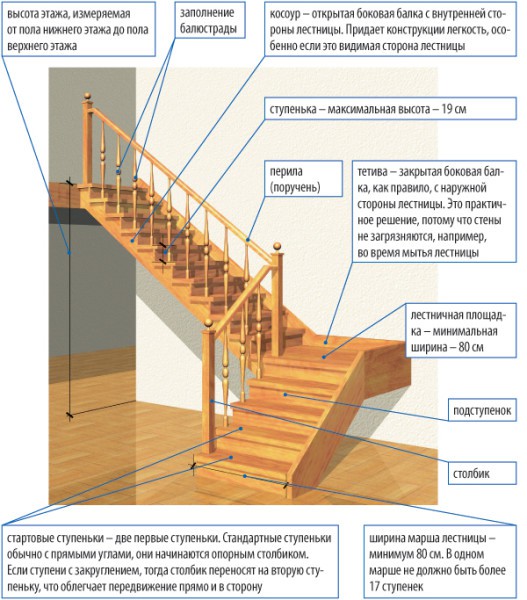

Railings for any design can be:

- Wooden with various design (carving, etc.).

- Metal (simple or with forged elements).

- Concrete (on their surface from the front and the inside it is necessary to apply finishing material).

What is porcelain tile

Porcelain tile is one of the subspecies of ceramic tiles.

It is made from:

- Clay dough (several types of clay).

- Feldspar.

- Quartz.

- Various mineral dyes, with the help of which the original design of the material is created.

Note. It has excellent properties and characteristics. The main advantage will be the affordable cost of such material and the possibility of creating with its use an interesting and original design of steps.

Properties of porcelain tile:

- Porcelain tile has high strength. All this is achieved for the reason that it includes feldspar and quartz, which are involved in the natural formation of granite.

- Double firing of porcelain stoneware also plays an important role, which gives even greater strength due to the formation of a very dense material structure.

- The material is available in tiles that have different sizes, so you can always choose the best option for another design. All work is done by hand, as they are similar to installing a simple ceramic tile.

Material:

- Durable and reliable, its service life is at least 20 years.

- Moisture-resistant, since the surface is exposed to high temperature and is coated in this process with a protective layer with or without glaze.

- Practical, does not require special care.

Tip. There is a type of porcelain tile that has small pores on its surface. It is not recommended for finishing steps, as frequent cleaning with abrasive products will be required.

- Wear-resistant, the surface is not subject to abrasion and various mechanical or physical influences.

- It is frost-resistant and does not respond to high temperature conditions.

Note. Due to its properties, such material can also be used outdoors.

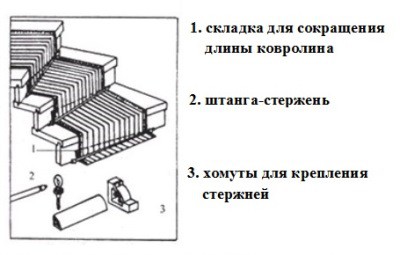

How to mount porcelain tiles on the steps

Porcelain stoneware has been used for a long time.

For its installation you will need:

- A special adhesive that, after drying, has high strength or a simple concrete mortar, which is prepared independently from water, sand and cement.

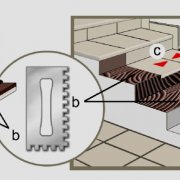

- Spatula for applying mortar or trowels.

- Mixing tank and construction mixer for high-quality mixing.

- Building level and tape measure, pencil.

- Tile cutter for cutting porcelain tiles.

- Cross beacons for even distance between tiles.

Tip. Before installing porcelain stoneware, it is worth treating the surface with a primer to increase the bond with the surface of the adhesive solution.

Work:

- The principle of operation is similar to the installation of ceramic tiles. The solution is superimposed on the inner surface of the granite.

A cross-shaped beacon is inserted between each tile during installation.Obligatory will be after installation to mask all seams with decorative putty. - There is another way to install porcelain stoneware - on the frame. Only when decorating a flight of stairs it is not used often. This is due to the fact that the frame has its own specific height.

Tip. If you plan to use the latter method of fixing porcelain stoneware on the surface of the steps, then it is worth considering the height of the frame and the height of the steps when manufacturing the staircase itself.

- This method involves the use of special profiles, which are mounted using dowels on the surface of the steps. On the back side of the porcelain tiles special locks are attached, which are also located on the profiles.

The video shows two installation processes of porcelain stoneware.

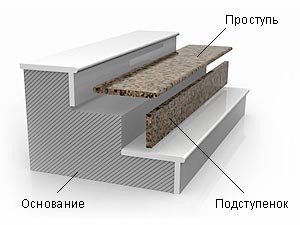

Granite in the facing of the steps

Facing with granite steps is distinguished by its originality. This natural material has almost the same properties as porcelain tiles, only its strength is much higher.

Tip. It should be noted that the surface of the granite should not be cleaned with abrasive detergents or cleaners, as it can begin to deform.

Work Stages:

- Installation of granite tiles is not difficult. But, everything will depend on the size of the material itself and on its mass.

Granite itself is quite heavy in weight. Very often, the lining of the steps of granite is used to cladding the outer staircase. - It is best to mount granite slabs on a concrete mortar, the strength and density of which is regulated by the amount of sand used. So the proportions of its manufacture are 1 bucket of cement for 3 similar in volume buckets of sand.

A bucket of sand is simply removed to increase strength.

Note. You can also use special glue, which is intended for the installation of natural stone.

Marble for cladding flights of stairs

Facing steps with marble is distinguished by its luxury. This material was used in past centuries for the decoration of castles. It is quite expensive in value.

Its surface is glossy or matte. There is a wide variety of colors.

Characteristics:

- Light marble is used to decorate wall or other surfaces. But dark shades (green, brown, and so on) are suitable for finishing steps.

- Mounting it is quite simple, as for interior decoration this material is made in tiles 1 cm thick.

Tip. Quite often, concrete mortar is used to install marble tiles.

- Only due to its properties and characteristics it is able to withstand a large weight of material.

According to its technical indicators, marble is very similar to granite and porcelain stoneware; it:

- Moisture resistant and wear resistant.

- Durable and reliable.

- It is frost resistant and does not burn. Withstands various temperature conditions.

- Wear-resistant and durable, since it cannot be said that marble slabs of natural origin have a certain life.

For installation, you will need a similar tool as for fixing on the surface of porcelain stoneware.