Finishing wood with a metal staircase: doing it right

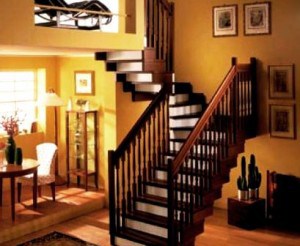

The metal staircase, decorated with wood and forged metal elements, looks not only as a highly artistic element of the interior, but also the final, stylish figure or architectural design of the chosen stylistic direction. Finishing wood with metal stairs gives the construction additional rigidity, safe and comfortable movement, convenient descent and ascent to family members of any age, regardless of their physical abilities.

Looking through photos and videos, you can notice that a successful design decision in the decorated interior is a combination and combination of durable metals and natural wood on the stairs. The nobility and respectable, luxurious look give the room wood and metal.

The content of the article

Material for decorative elements

A traditional material in the manufacture of metal substrates is a light, but sufficiently strong grade of metal having the properties of increased resistance to corrosion. Stairs wood has certain lining requirements.

Here it is better to choose only a natural massif:

- Wood is famous for its attractiveness, durability, and has the properties of increased thermal insulation. No other material brings more warmth and coziness, comfort and harmony, natural freshness and luxury than natural wood.

- The most popular veneers for carrying out facing works were oak, walnut, pear, beech, ash, and mahogany on top of Olympus. Oak wood is characterized by increased durability and strength, rich colors, which eventually darkens a little, acquiring a deep noble color.

- Strength ash stands on a par with oak, has a pronounced texture and a noble grayish tint.

- Connoisseurs of elegance and sophistication in style will appreciate beech wood. It is characterized by attractiveness, durability and a homogeneous structure, perfectly imitates mahogany.

- The wood of exotic species of trees, which include teak, wenge, merbau, will delight with incredible color tints. Lemon yellow and deep purple tone, brown and black, deep red and their combination in the same compositions, give just a great effect.

In addition to color qualities, the staircase faced with this material serves for many years, delighting the inhabitants of the house. - On the risers, it is recommended to use pine, spruce, fir wood, the price of which is much lower than hardwood. The low density of wood does not create problems of its processing.

Attention: The moisture content of wood for cladding should not exceed 12%, otherwise wood products, after a while, will swell.

- The most important characteristic of wood is its moisture content. Freshly cut tree has 35-100% humidity.

If facing materials are prepared at home and with your own hands, you need to understand that excess moisture significantly reduces the strength properties of wood, and it must be dried to the desired rate. - After lining the metal stairs with wooden elements, they are processed with special compounds and means that prevent further cracking and rotting during further operation.

The best solution is wood cladding

The metal staircase, lined with wood, looks elegant, especially if combinations of several types of wood are used. The combination of colors, textures, various shades and the play of colors delight and surprise guests for decades.

Varieties of stairs

There are no ladders with one support plane. Stairs serve to connect the premises spaced along the height, and perform the function of the necessary movement to a given object.

Stairs are structurally divided into spiral, marching, spiral and combined. In addition to the flight of stairs, the rest relate to non-standard solutions and designs.

Development and accounting of projects for individual cottages and flight stairs in them do not contradict the notion that this type of stairs can be attributed to the same category as the other stairs.

So:

- The length of the steps refers to the individual size. When choosing them, public buildings provide for the possibility of evacuating working personnel in extreme and emergency situations.

In a private building, their length can be significantly less. - Staircase woodworking is a creative and fun process. Steps welded from the corner or all-metal, how to clad and with what? What materials to choose?

- Fencing stairs, but this is a field of activity with boundless horizons and human fantasies. Fencing is carried out with wood, metal, a metal bar from a straight or twisted square, art forging with a pattern, corresponding and emphasizing the interior of the room and its individuality.

Attention: It is convenient and practical to fix wooden handrails, in which a groove is provided, to metal plates. In this case, the metal plate is hidden in the handrail.

- The crossbar filling is not excluded, when with rarely spaced vertical racks, several crossbars located parallel to the angle of inclination of the stairs are fixed.

How to make and what is necessary for facing

Finishing a metal staircase with wood allows you to achieve two goals at once:

- Decorative properties are improved, and a presentable appearance is acquired.

- Increased performance.

- It is necessary to prepare wood for metal finishing.

- Varnish, carpentry tools.

- Mounting studs, screws and nails.

- Plumb, line and level.

The design of the stairs is selected, the instruction is studied, the method of plating the metal frame is selected:

- With or without risers.

- Wooden railings with balusters are made or metal roof rails are selected.

- The structure looks representative with a fully welded welded frame, with wood trim elements.

- A decision is made on the material for the steps. It is important to follow and adhere to the main rule that the upper part of the degree (overlays) is made of wood that is resistant to wear - ash, oak, beech.

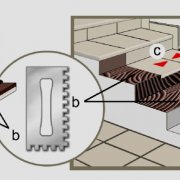

Finishing the vertical gaps between the steps is done by glued oak or softer wood. Spruce or pine under the carpet will look quite appropriate. - Wood trim stairs begins with the preparation of cladding elements. The material is adjusted to the size of the frame in such a way as to avoid gaps.

Why wooden parts for steps are pre-measured and numbered one after another. - The type of balustrade is selected, which simultaneously performs the protective function of the fence and is a spectacular staircase decoration that defines the first impression of the appearance of the structure. Handrails are available in different sections, it is necessary to choose the most comfortable form for your hand.

Attention: Choose the optimal gap for the arrangement of balusters on the stairs equal to at least 130 mm with a convenient width of the steps.

- Wooden elements are installed. The upper part of the step is fixed with screws.

- The risers rest firmly against the frame and are also fixed. Similarly, work is performed along the entire length of the structure.

- Columns and balusters are placed on the edges of the steps from the beginning to the end.

- Their vertical installation is checked, the elements are fixed with special studs and a railing is installed on them.

- The frame is sutured completely. The side of the stairs is closed with a wooden panel that repeats the shape of the steps.

For the finishing of metal marches of the rear part of the structure, the same panels or sheets of drywall are used. This work is carried out immediately after sheathing the steps and performing the risers. - All wooden elements of the stairs are varnished and allow time for drying.

The finished design will look much more attractive if the wooden panel is 2-3 cm larger than the metal step. The plating of a metal staircase with a tree looks especially chic when combining various types of wood.

Indeed, the best solution is facing the stairs with wood. This is as practical as possible. Yes, the appearance can be beaten and, if desired, changed over time without special frame alterations by varying the shape and color of the wood finish and another important factor is the environmental friendliness of such a finish. We are already quite often surrounded by stone, concrete, the same tile, living material is now little used, expensive, but in vain.