Painting heating batteries: dye selection, surface preparation and application of paint

Our topic today is DIY heater painting. We will find out what paints can be used for radiators, how to properly prepare the surface of the heater for painting and how to perform it.

The content of the article

To the store

First, let's decide how to paint the batteryso that she retains her color for a long time.

A common problem with the most popular oil and alkyd enamels is that they change color at high operating temperatures. More recently, a snow-white radiator acquires an untidy yellow color.

The heat resistance of the paint is indicated by the inscription on the package: “heat-resistant” or “for radiators”.

However, not all heat-resistant paints are the same in their operational characteristics:

- Dyes based on organic solvents (alkyd and organosilicon) have moderate toxicity and a pungent odor that persists for several days after painting;

- Acrylic water paints, on the contrary, are odorless, but temperatures above 100 - 120 degrees are not available to them;

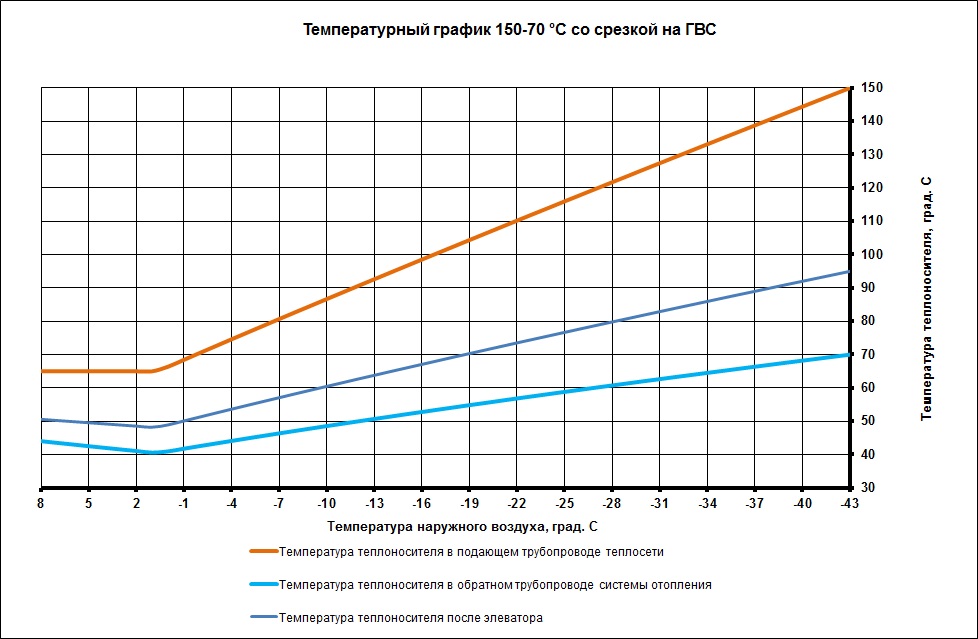

However: the current regulatory documents limit the maximum temperature of the coolant in the central heating system to 95 degrees. In autonomous heating systems, it is usually even lower - 50-75 ° С.

- The drying time of the dyes also varies markedly: water-based acrylic paint is ready for application of the second layer in an hour, and alkyd dries for at least 3-6 hours.

Sample research

To understand how to paint heating batteries in your case, get acquainted with the characteristics of several paints on different bases. All the samples that we are going to meet are produced by the domestic company KrasKo.

Radicore

| Parameter | Value |

| Structure | Solution of melamine formaldehyde and alkyd resins in an organic solvent, heat-resistant mineral or metal pigments, film-forming filler |

| Heat resistance | Coating strength is maintained up to a temperature of + 120 ° С, color - up to a temperature of + 80 ° С |

| Texture | Semi gloss |

| Features | The manufacturer allows painting on rust (except for plastic) and old coatings subject to their strong adhesion to the base |

| Thinners | Solvent, xylene |

| Layer Drying Time | 4 hours at room temperature |

| Permissible room temperature during painting | +5 - + 40 ° С |

| Permissible radiator surface temperature | Up to + 60 ° С |

| Layer Consumption | 70-140 g / m2 |

| Price | 283 rubles per kilogram |

Aquametallic

| Parameter | Value |

| Structure | Aqueous dispersion of acrylic polymers, corrosion-resistant pigments, corrosion inhibitor |

| Features | Flavourless, fireproof, suitable for exterior and interior use. It can be applied on durable old coatings (except enamels and primers based on nitrocellulose) |

| Heat resistance | + 110 ° С (short-term, not more than two hours, heating to + 130 ° С is allowed) |

| Diluent | Water |

| Application Temperature | +15 - + 30 ° С |

| Layer Consumption | 200-250 g / m2 |

| Layer Drying Time | 1 hour at room temperature |

| Price | 263 rubles per kilogram |

An important detail: the vast majority of water-dispersion paints are produced in only one color - white. If a different color is required, the dye is tinted with water-soluble pigments (taking into account the requirements for heat resistance - metal or mineral).

Celsite-500

| Parameter | Value |

| Structure | Suspension of solvents and pigments in silicone varnish |

| Areas of use | Painting of heating appliances, oil and gas pipelines, furnaces and boilers, chimneys and exhaust pipes of automobiles, steam pipelines and technological equipment. Application on concrete, plaster, asbestos cement and brick is allowed |

| Heat resistance | From -60 to + 500 ° C |

| Features | Resistance to fuels and lubricants |

| Thinners | Xylene, solvent, R-646 |

| Application Temperature | -20 - + 40 ° С |

| Drying time | 2 hours at +20, 30 minutes at + 150 ° C |

| Layer Consumption | 110-150 g / m2 |

| Price | 309 r / kg |

Curious: the organosilicon is better known to us under the borrowed name “silicone”. The family of heat-resistant silicone paints is not called silicone, to avoid confusion with interior and exterior silicone water emulsions.

Texture

The better to paint the radiators - matte or glossy paint?

Let's put it this way: each solution has pros and cons.

Gloss is less than grades: its properties are determined by a perfectly smooth surface that does not trap dirt. The flip side of cleanliness and spectacular shine is that even irregularities are visible on the glossy surface. And on the old cast-iron radiators, of course, they are.

The matte surface gets dirty more, but minor defects are almost invisible on it.

Expenses

How much does it cost to paint a heating battery with your own handspaying only for materials?

The surface area of one section of the cast iron radiator MS-140 is 0.21 m2, seven-section battery - 1.47 m2. To calculate the cost of painting heating batteries, you need to calculate the product of the area, paint consumption per layer, the number of layers and the price of a kilogram of dye. Of course, all values should be in SI units - square meters and kilograms.

So, when using Celsite-500 in three layers, painting a seven-section radiator will cost 1.47 (battery area) x 0.150 (paint consumption per layer in kilograms) x 3 (number of layers) x 309 (price per kilogram) = 204.4 rubles.

It is worth clarifying: 309 rubles per kilogram Celsite is in bulk. In real conditions, for painting one battery, the owner will have to buy a can weighing 0.9 kg and cost 337 rubles.

Surface preparation

Preparing the battery for painting comes down to stripping from old coatings and (if necessary) degreasing.

Old paint is brushed with a metal brush. It is most convenient to use a cord brush for a grinder.

A particularly thick layer of paint can be removed with a spatula, previously softened in one of two ways:

- By applying a universal wash to the surface of the radiator;

- Warming up the section section with a building hairdryer.

However: only the channels of the sections can be warmed away from the hoses and collectors. On eyeliners, strong heating can burn the winding of threads, on collectors - intersectional gaskets.

Degreasing for painting is carried out with gasoline, acetone, solvent or any other organic solvent. It is only necessary if oil-grease stains are visible on the surface of the radiator.

Painting

What tool paint the battery?

Brush or spray gun.The first option is bad because the brush leaves streaks, the second - a large inappropriate use of paint and the need for careful protection of walls and floors (if, of course, the battery is painted without dismantling).

Subtleties in painting a little:

- A primer is necessary only for alkyd enamels, and even then not for everyone. In general, glyphthalic GF-21 is used;

- Unless otherwise specified by the manufacturer, proceed with painting only after turning off the heating. If you paint a hot surface, you can get an uneven coating and drips: the paint will dry faster than you distribute it with a brush on the surface;

- Paint the section from top to bottom to avoid drips;

- When using paint on an organic solvent, open the windows;

- Rust on the battery after painting means flow between sections.

It is eliminated by tightening or replacing the intersection gasket. After repair, the connection sections will have to be repainted.

Conclusion

As you can see DIY battery painting not difficult and does not require large expenses. Learn more about paint technology. video in this article. Good luck!

Painting heating batteries: Video