Primer consumption of deep penetration per 1 sq.m

No type of finish, with the exception of those produced in a frame-like manner, can do without the operation of priming surfaces. But not everyone knows what formulations are used for this purpose, and by what criteria they are selected.

This, or a similar question: “Consumption: a primer for deep penetration”, which Internet users ask with enviable consistency, requires a correct answer. We will try to cover this topic in as much detail as possible, and offer a video as a good example.

The content of the article

Why primer the base

The purpose of applying a primer is to provide the most durable adhesion of the finishing layers to the base (seeWhy do we need a primer: technological nuances of finishing work) But the base surfaces are different, and not only in the type of material from which they were built, but also in their structure. Believe me, there is a huge difference between the freshly applied plaster and the old plaster from which sand is poured.

If in the first case it is necessary to ensure only adhesion, then in the second, the surface also needs to be strengthened. To do this, use special reinforcing primers, which are modified by the addition of polymer resins. They bind loose particles on the surface, forming a sufficiently strong film, which will allow for a high-quality finish.

A deep penetration primer will help to strengthen the porous surface, the consumption of 1 m2 of which, first of all, depends on the initial state of the floor, walls or ceilings. The type of base also matters, therefore, it is necessary to select the composition, not only based on the variety of paint used.

Adhesive and penetrating compounds - what is the difference

Conventional adhesives, which manufacturers often call "Concrete contact", Used on surfaces that do not need to be strengthened. They in one or two passes with a primer form a film on the surface, due to which moisture from the plaster, paint or glue will not be absorbed into the base.

- This is very important, since moisture loss affects the setting process, and, accordingly, reduces the strength of the coating. When the base is porous, then naturally, it absorbs moisture much more. Accordingly, the primer should be designed for highly absorbent substrates.

- This option is called penetrating - or a primer of deep penetration. The ability of a primer to penetrate the thickness of a surface depends only on the size of the particles present in it. The strength of porous substrates - even if it is not old plaster, but cellular concrete, is quite low.

Note! The deeper the primer can penetrate, the thicker the hardened surface layer will be, which will serve as the base for the new plaster. The screed, regardless of its composition, has high strength, and it should not be higher than the strength of the base. Otherwise, its peeling is inevitable, so it is so important to strengthen the base surface.

- We think from the above it is clear that the use of deep penetration is far from always justified.And the point is not that it has a higher price - just on a weakly absorbing surface such a primer will create an almost glass film, which, on the contrary, will only complicate subsequent work.

When choosing a primer, this must be taken into account, since the manufacturer’s instructions cannot give the consumer so complete information. The label only indicates what types of surfaces the composition can be applied to, and only those who are going to finish should evaluate their condition.

Consumption

Soil flow rate also depends on the absorbency of the substrate - the number of layers applied also matters. Adhesive primers are usually applied in a single layer, and on normally absorbent surfaces, their flow rate is about 150 ml / 1m2. On porous surfaces, for example, on a wall of foam blocks, the flow rate will already be at least 250 ml / 1m2.

By the way, there are also concentrated formulations on sale that are diluted with water 1: 2, 1: 5, or even 1:10 before use. In the latter case, with a five-liter capacity of the concentrate, you get 50 liters of ready-to-use primer - and this is very profitable, even despite the fact that it costs a little more.

Varieties of primers and their application

There are several varieties of surfaces that have to be primed during the construction process. The composition of the primers, as a rule, is focused on a specific type of substrate - after all, there is a difference that is in front of you: a wall of silicate brick, or a paneling made of chipboard, which must be puttied (seeHow to putty walls in different versions) and paint.

How to treat a mineral base

All types of mineral substrates, which include concrete and clay brick surfaces, plaster walls and plasterboard cladding, cement and gypsum plasters, preferably primed with mineral-based formulations. Only, since cement or gypsum is present in them, a choice should be made in accordance with this.

However, the type of coating applied is also important, and if, for example, polymer-cement or gypsum plaster is applied to a concrete wall, it is better to use a universal primer. This is due to the presence of butadiene, acrylates, or styrene in the copolymers.

Polymeric additives to a large extent correct not only the characteristics of plasters, but also primers. In addition, they can reduce the consumption of soil mortar to 100ml / 1m2, which fully compensates for their higher cost.

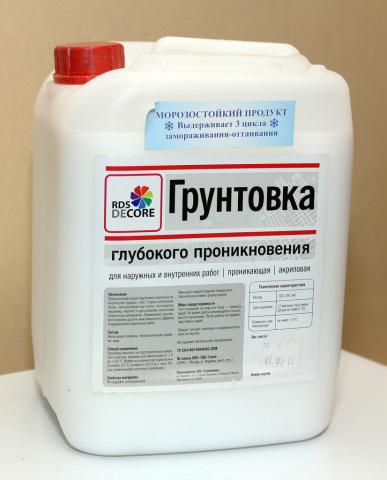

For example, Unis primer, which is shown in the photo above, can be applied not only to substrates made of heavy and cellular concrete, gypsum and silicate surfaces, but can also be used on wood.

What is better for the facade

The surfaces of the masonry of silicate brick and gas silicate blocks, as well as plaster, in which lime is present, also belong to mineral bases. But since lime easily enters into chemical reactions not only with other substances, but even with water, it is better to take a silicate primer for such bases.

So:

- It is based on liquid glass, which penetrates deep enough into the thickness of a wall or ceiling, and forms a strong, and most importantly, vapor-permeable surface. This quality is extremely valuable when it comes to exterior walls, so this type of soil is used only for facades.

- In rooms, the same surfaces are best treated with modified primers, which to some extent prevent the steam from entering the wall. As for outdoor work, then, perhaps, the best option can be considered a silicone primer.Due to its structure, in which both organic and inorganic substances are present, it is a kind of intermediate option.

- The silicate primer has a rather narrow scope, since it is used purposefully, only on calcareous surfaces, and under silicate paint. The silicone composition is suitable for all but concrete surfaces - for which mineral soils are better suited.

- Even the walls, previously plastered with silicate plasters, or painted with the same paints, are perfect for silicone primers as a base. It is combined with most types of paints, except for organosilicon and some types of coatings, intended exclusively for application to metal.

Consumption of silicone primers is slightly higher than that of conventional adhesives, but they can smooth out minor surface imperfections without first applying putty, which in itself saves both time and money.