Putty Bark beetle for exterior and interior decoration

Do you want a beautiful and reliable finish for the facades of your home or an original coating for interior walls? Are you going to do the job yourself?

Choose a putty with an unusual name Bark beetle. It is quickly and easily applied, dries almost instantly and reliably protects the walls from any external influences, giving them a completely original look.

Do you know anything about this material? Then this article is for you.

The content of the article

Characteristics and material properties

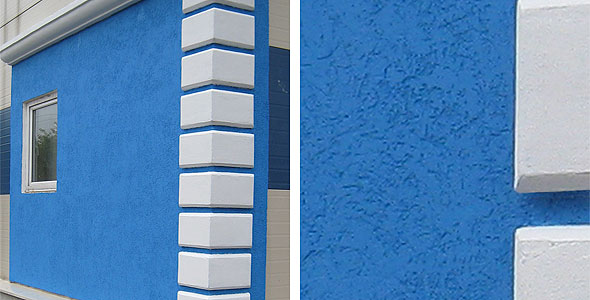

The appearance of the finished coating resembles in its texture wood bark, eaten by a bark beetle - hence the unusual name. This effect is due to the presence of solid mineral particles in the putty.

The relief of the pattern and the thickness of the applied layer depend on their size, in different compositions varying from 1.5 to 3.5 mm.

Note. The thickness of the putty layer cannot be less than the grain size, and the material consumption depends on the thickness. Consider this when buying.

Putty Bark beetle is sold in the form of dry bulk mixtures based on white cement or in finished form in buckets.

In the latter case, we are talking about polymer mixtures, which can be:

- Acrylic

- Silicone;

- Silicate;

- Silicate-silicone.

Regardless of the type, the material has high operational and weather-resistant properties, can be used for both indoor and outdoor decoration.

The fundamental difference between cement and polymer putty is that the first is to be painted after application and drying, and the second can be tinted even in a bucket. Or immediately buy a mixture of the color you want.

In addition, it is more durable and better resists mechanical damage, has the ability to self-clean. The price of polymer compositions is much higher than cement, but the possibility of applying a thinner layer and the absence of the need to paint the finished coating can significantly save money.

The basis for applying putty bark beetles can be a variety of materials:

- Concrete;

- Brick;

- Cement-sand plaster;

- Expanded polystyrene;

- Plywood;

- Chipboard;

- OSB.

Note! Do not apply decorative putty directly on a dry or clean gypsum plasterboard surface. Before this, it must be puttied with a polymer compound of the Shetrok type.

Technology of wall decoration with decorative putty Bark beetle

All work on decorative finishes can be divided into three main stages: surface preparation, puttying and grouting to give the desired texture.

Surface preparation

The main preparatory work is carried out according to the standard scheme:

- The surface is cleaned of loose stucco, protruding influx of mortar, dirt, etc .;

- Then, if necessary, the level is removed by ordinary plaster or putty, while the maximum size of the irregularities should not exceed the size of the grains contained in the bark beetle.

And then the differences begin. The walls need to be primed, but not with the usual primer of deep penetration, but with a special primer paint, tinted in white.

Ideally, when using colored polymer putty, the color of the soil should match the color of the decorative coating.

Primer (see Primer walls and all for that matter) Is a very important stage on which the quality and durability of the coating, its decorative properties, depend.

Priming technology depends on the condition of the substrate:

- If it is covered with oil paint, it must be scraped off or sanded;

- When decorating walls in which metal elements are present (staples, nails, self-tapping screws), they are first treated with one or two layers of waterproofing soil to prevent rust on the surface;

- If the base is very porous, it absorbs moisture well, then before the main finish it is covered with an acrylic primer of deep penetration.

Tip. Look in the store for a suitable primer of the same manufacturer as the selected putty. Materials of the same brand are best combined with each other, ensuring maximum quality and reliability of the finish.

Putty application

You can start applying Bark beetle immediately after the paint-primer dries. Its drying time depends on the composition and manufacturer, the instruction on the package contains all the necessary information.

While the soil is drying, prepare the necessary tools:

- A large bucket for kneading putty (if dry mix is used);

- Construction mixer or drill with nozzle;

- Stainless steel spatulas - narrow and wide;

- Plastic grater.

Mixing dry putty should be strictly observing the proportions of powder and water indicated by the manufacturer, and in such an amount that you manage to work out during its viability. Finished formulations before application need only be mixed well until smooth.

Tip. Do not use the putty from the bucket completely. Having consumed half, pour the mixture from the following can into it and mix thoroughly. This will avoid coating inhomogeneity.

Putty is applied in the usual way. But, since it dries quickly enough (see How many different types of putty dries), this is done in small areas, which after 5-30 minutes after application (depending on the brand) should be structured with a plastic grater.

It is advisable to lay bark beetle in continuous strips along the entire length or width of the wall, making the edges torn to smooth the border with the next strip.

Another feature of applying this material is the thickness of the layer. It should correspond to the size of the grains added to the putty. And keep in mind: material that has fallen to the floor or to the ground cannot be selected and used for its intended purpose.

Grout

This is the most interesting, creative stage of finishing, during which the desired pattern is attached to the surface. You need to start it at the moment when the putty ceases to shine moistly and stick to the spatula.

The manufacturer always indicates the time, but it can vary in one direction or another, depending on humidity and air temperature.

The most common and simple patterns that are created during the grouting process:

- Rain - the grater is pressed to the surface in the upper part of the wall and is diagonally downward;

- Crosses - first, a continuous long movement is made with a grater from top to bottom, then short “strokes” horizontally;

- Lamb - obtained with circular motions.

Having preliminarily trained on the back wall of the house, you can choose a suitable pattern or come up with your own and fill your hand.

Tip. Prepare a bucket of clean water in advance to wash the grater as it becomes soiled.

If you putty the walls without an assistant, then when grouting do not bring the grater to the border of the applied layer. The pattern in this section is performed after the next section is processed.

If you used colored polymer putty, this is the end of the job, you just have to wait until it dries. If painting is to be done, then it is performed after the coating has dried, which requires at least six hours.

Conclusion

In conclusion, I would like to recall that Bark beetle, like any other putty, should be applied to the walls in warm, but not hot weather. Facades are not recommended to be finished in the rain or in direct sunlight.

The video in this article will help you consolidate what you read and clarify some difficult points.