How to plaster the house outside: make a choice

To the question: “What is better to plaster the facade of the house?”, It is impossible to answer unequivocally. The choice of plaster material depends on the type of base being trimmed, the presence of complex architectural elements in the building’s exterior, and the design of the coating.

It also matters in what way: manual or machine, the solution will be applied. And in general, taking up such a type of finish as plaster, you need to measure your desires with your possibilities, since far from everything you like, you can do it yourself.

We think that the video in this article, as well as the useful information presented to your attention, will help you make the right decision.

The content of the article

Facade Plaster Requirements

Since the surfaces of the outer walls are constantly exposed to atmospheric factors, it is only natural that it should be resistant to high and low temperatures and their sharp changes. Plaster is not only a protective “shirt” for structures, but also their decorative coating, so it should have both strength and a certain aesthetics - although there are still some nuances.

You don’t have to understand all the features of the material if you entrust the work to a trusted master. This will save energy, time and guarantees that the work will be performed efficiently.

Vapor permeability

When deciding how to plaster a house from the outside, one should not forget about such an indicator as vapor permeability. It is especially important when a similar type of finish is provided for aerated concrete walls.

Note! Due to its porous structure, cellular concrete is easily permeable to vapors, which inevitably form in heated rooms. When there is an unhindered exit for them, there is nothing to worry about. But if there is an impenetrable film outside the foam-block or gas-block walls, then the structures will accumulate moisture and quickly collapse - and this should not be allowed in any case.

So:

- Kneading the solution yourself, it is quite difficult to provide the coating with all these qualities. Usually this is done in order to reduce the cost of decoration, but when it comes to cellular walls, savings are inappropriate. For their plastering, it is better to use a specially designed factory mixture - even if its price seems to you not quite budget.

- But you do not have to worry about how to plaster the facade of the house, or about how to provide the coating with the necessary properties. A certain coefficient of vapor permeability is inherent in all facade plasters, because steam is formed from the inside of the building, and must somehow go outside.

Heavy concrete and brick do not accumulate so much, so ordinary cement and cement-lime mortars are suitable for plastering them. They can be made independently without problems - there would be an instruction. In working with them, only two nuances are important: the quality of the base foundation, and the final result that you are striving for.

Strength

It is one thing to plaster a barn or a garage, and it is quite another thing to perform high-quality decoration of the facade of the house. Not only the technology of the production of works, but also the flow rate of the solution depends on the quality and type of the base base. To smooth the curved brick walls, sometimes you have to apply a screed, the thickness of which in places exceeds 5 cm.

- Most facade plasters are thin coat - that is, the thickness of the applied layers is not more than 2 mm. Aligning a wall with significant defects is simply impossible at such a pace. The question immediately arises: "How to plaster the house outside in this situation?" The answer is simple: if the base requires a thick layer of mortar, it is best to use M150 sand concrete as a starting plaster.

- This material is a pre-mixed dry mix.consisting of fine sand, Portland cement, lime and additives that regulate the process of shrinkage and hardening of the screed. The universality of sand concrete is that it can be used not only for plastering surfaces, but also for other construction works: pouring floors, tiling, masonry and brickwork.

Note! The building code states that with a screed thickness exceeding 20 mm, plastering must be done on a grid. But the characteristics of some modern materials that appeared after these rules were developed allow applying thicker layers without reinforcement. So, the use of sand concrete makes it possible to do without mounting the mesh with a layer thickness of up to 30 mm, which allows you to get some savings.

Modified universal mixtures are inexpensive - a little over a hundred rubles per bag weighing 40 kg. This amount is enough, with a layer thickness of 10 mm, for plastering 2.3m2 of wall. For the money it will turn out 52-55rub per m2 - and it’s not a fact that buying all the ingredients separately and mixing the solution yourself is cheaper.

Beautiful reliefs for exterior walls

Whatever type of finish you prefer, the plastered surface must be leveled. The fact that the sand concrete mixture is best suited for this purpose, we have already said.

Further actions depend on what you want to get as a result. The best version of decor for facade walls is a relief coating, but here are some ways to create it, which we will describe later.

Fur coat

The most inexpensive and practical option for exterior walls is a gray “fur coat” (seeFacade plaster coat: features of use) For its implementation, the most usual plaster mortar is suitable, and if it is made and applied correctly, the coating will serve for many years. But today there are dry mixes and ready-to-use decorative plasters from the manufacturer, designed to receive such a relief.

However, the name seems to be the same, but the result is different - like heaven and earth:

- The aesthetic effect of the coating depends on the type of filler - and this can be not only quartz, but also marble sand. Its fraction also matters, since the larger the filler, the more coarse and voluminous relief is obtained as a result. Well, of course, the appearance of the coating depends on the shade that the solution gets when tinting.

- All decorative plasters, with the exception of those intended to simulate concrete, are made on white cement - this facilitates the process of tinting them. It’s useless to paint surface gray stucco - anyway, it will shine through. Of course, the price of a factory mixture is much more expensive than a normal solution, and costs at least 400 rubles. per bag 25kg. If the filler is marble, then this figure can be three times higher.

- But, back to the gray coating. This is the most economical option, since neither tint the solution, nor produce a final stain (see DIY decorative plaster painting), in this case will not have to. Then, as a material for applying a fur coat, you can use the same sand concrete mixture - purchased, or made independently.

- The ratio of components in the solution depends on its brand and brand of cement. You can, of course, prepare the usual cement-sand mixture, but the coating from it turns out more coarse and poorly machined. To improve the plasticity of the solution, hydrate or carbide lime (lime dough) must be added to its composition.

Note! By consistency, the solution for the "coat" should be more liquid than for an even screed, since it will have to be sprayed, and it should not adhere to the surface with cakes.

- To obtain a mortar of grade M50, based on cement M300, the proportions will be as follows: for 1 part of cement; 0.4 parts of lime; and 5 parts of sand. Usually, for a facade coating, such a strength of the mortar is enough, and its adhesion can be enhanced by treating the base with an acrylic primer.

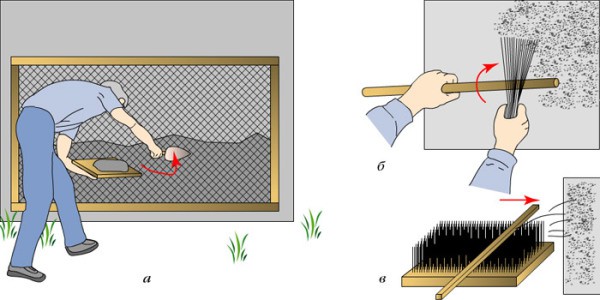

- As for spray technology, there are no special rules. Professional plasters apply the solution with a pneumatic or electric hopper. Those who work in small volumes use devices in the form of a wooden frame with a mesh-net stretched inside it, through which they spray - the larger the cell - the larger the tubercles of the “fur coat”.

- If you need to plaster only the basement of the house, brick or concrete porch, garage, then you can spray and in the old fashioned way: using a stick with a hard brush or a broom made of twigs. It is worth saying that these methods of performing relief are used only when using a home-made solution.

- Expensive decorative plaster from the manufacturer, it is unlikely for anyone to come up with a spray. Apply it with the help of a Venetian trowel, and it looks something like this. The first layer, the thickness of which usually does not exceed 1 mm, is thoroughly smoothed.

- A drawing is created without waiting for it to solidify: a mixture is applied to the trowel and “blots” are randomly applied with it. Where the solution has adhered, tubercles remain; scratching ridges are removed on them after 24 hours with an abrasive mesh. After removing the dust, the plaster is covered with a glazing composition - and the fur coat is ready.

- There is also a relief called a “grated coat”. It can be done both on a coating made by homemade mortar, and on purchased decorative plaster. To obtain the effect, scallops of the still-dried fur coat are lightly pressed with a trowel.

In this case, the coating after hardening will not have to be “combed” with sandpaper. Well, so that the finish of the exterior walls has such a rich color, which we see in the photo above, it is obviously not enough to color the solution in the mass. For this, the surface must also be painted in the traditional way.

Bark beetle

In some factory plasters designed to obtain a “fur coat” relief, the effect is achieved only due to the large filler present in their composition. It makes the structure of the screed grainy, and for decoration this is quite enough even without additional processing of the layer.

- This variant of decorative coating is usually performed on a well-leveled surface in one layer, it is allowed to dry well, and then finish painting is performed. Almost the same can be said of such a popular relief as “bark beetle” (see.Stucco bark beetle: application technology).

- In the composition of the plaster, designed for its creation, along with fine sand, there is marble chips with a fraction of up to 2.5 mm. When grouting a dry layer, the pebbles under the grater move, leaving characteristic traces similar to a wormhole in a tree. Actually, because of this, this relief got such an eloquent name.

- For its implementation, one layer is sufficient, the thickness of which must correspond to the fraction of the largest filler.Apply it with a trowel of stainless steel, laconic diagonal-spherical movements. The excess solution remaining on the tool blade, in which there are practically no large pebbles, is removed with a spatula.

- These residues are waste products that are no longer useful, so they are dumped in a separate bucket, and not in a container with working solution. About ten minutes later, as soon as the screed is a little grasped, they begin to overwrite it with circular motions, as a result of which a characteristic pattern is formed under the name “bark beetle”.

As for the color of the coating, the desired shade is achieved either by surface staining or by tinting the solution in bulk. Sometimes, in order to get a rich rich color, you have to do both.

Marble chips

Marble plaster even compositions are called that use not marble, but completely different stones: granite, malachite, jasper, and a coil. In general, it can be almost any natural stones with a beautiful texture, and often, they make up a certain combination.

So:

- The whole charm of such a plaster is that the coating does not get color due to the color, and due to the natural color of the stone. So that the base does not shine between the pebbles, only the adhesive primer is tinted, which is applied to the surface before plastering.

- The result is a weatherproof and impact resistant coating., which perfectly conceals even noticeable flaws on the base surface. Compared with the same “bark beetle”, in the marbled crumb decorative plaster, stones of more valuable breeds are used - here there are more of them in quantity, and the fraction is larger.

- It is not surprising that this type of coating is the most expensive.. The cost of material starts from 1250 p. for packaging weighing 15 kg - and 3000 p. for him is not the limit. For 1 m2, 2-3 kg of mortar is spent, so in private homes this finish is most often used only for facing the basement.

- I must say that the final effect of stucco with marble filling is completely different. It depends not only on the rock of the stone present in them, but also on its fraction. For example, Venetian plasters are fine-textured; in them, marble is generally ground into dust. Variants with the effect of "fur coat" and "bark beetle", which were described above, are attributed to fine-grained and medium-grained.

- Well, in order for the individual granules of stone to be clearly visible in the coating, a large fraction is needed. In compositions such as "marble chips", the size of the granules can reach 5 mm. It is from them that the mosaic plaster is obtained, which we see in the photo above. Such coatings are good not only for facades, they are also used in interior design - and not only for office ones.

- Mosaic plaster is ideal for decorating balconies and loggias.door portals, arches, vestibules. Such a coating looks gorgeous on the ceiling and on the fireplace wall. The undoubted advantage of this material is the simplest application technology: no drawings and multilayer screeds are required here.

The main thing is to carefully prepare the base: soak it twice - first with acrylic soil, and then with quartz, because it is more difficult for large pebbles with more significant weight to stay on a vertical surface. The coating is carried out in one application, and twenty minutes after that, it is treated with a protective varnish composition. Such plaster will dry for about six hours, and will serve until you yourself want to update it.