Facade panels for plaster

When facing building facades, it is important to achieve quality and attractiveness. Traditional plasterboard sip panels - a beautiful option, but expensive and time-consuming. An alternative solution would be facade panels for plaster, allowing, with similar practical properties and lower financial costs, to obtain a presentable appearance of the facade of the building.

The content of the article

Types of panels for plaster

Traditionally, the facades of the buildings were plastered. But the elastic plaster on the SIP panel is put for a long time. Faster and easier to use panels that mimic coatings for the exterior of a building. Finishing plates are presented on the market, including fiber cement and facade thermal panels for plaster. Their use opens up great possibilities for the design of both new and reconstructed buildings.

Fiber cement panels

They are plates with smooth or textured surfaces. For production use cement, inorganic compounds, wood fiber, mica and quartz. They are made with mounting accessories on the back for attaching to special profiles.

The material has good antistatic properties, so that even severe contaminants are easily washed off from its surface with water. It has good fire resistance and low coefficient of thermal expansion.

The advantages of fiber cement panels also include:

- ease of installation and handling;

- a large selection of textures and colors;

- environmental friendliness;

- resistance to rainfall;

- strength and seismic stability.

Thanks to the use of fiber cement panels in the decoration of buildings, it is possible to simulate the coating with common finishing materials, including stone and brick.

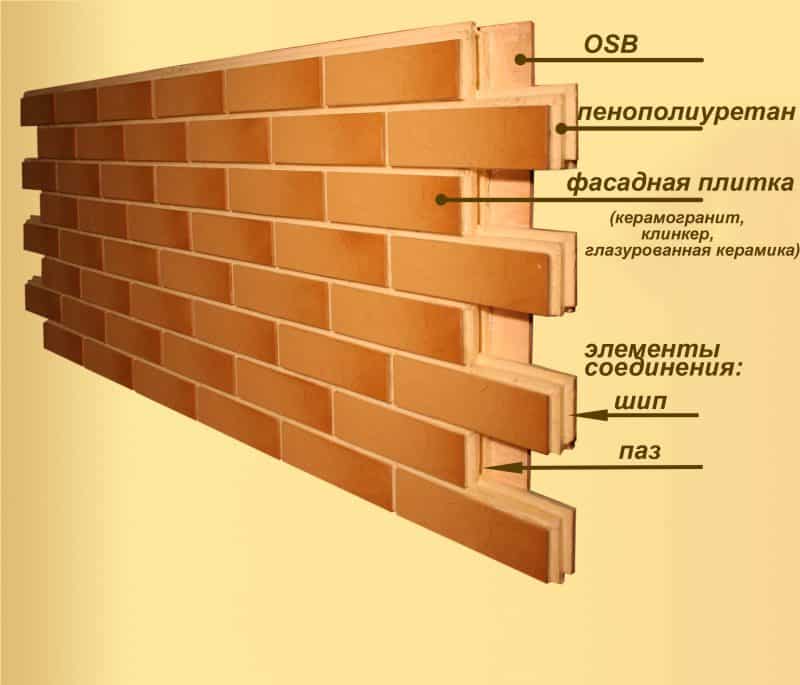

Thermopanels

By their design, these are sandwich sandwich panels. Represent a decorative finishing material with a heater based on polystyrene foam plate. The option of tight connection of plates by the method of "spike into the groove" allows you to get a beautiful smooth surface without visible seams.

Thermal panels for facade plaster have the following advantages:

- durability;

- ease of repair and maintenance;

- environmental friendliness;

- noise and heat insulation;

- resistance to mechanical stress;

- A wide selection of textures and colors.

This finishing material is also characterized by resistance to environmental influences. In addition, due to the low weight of the thermal panel, facade plaster can be used for the facades of old buildings with brick lining of the foundation. Such a foundation is not designed for heavy loads.

Well-known manufacturers of facade panels

Manufacturers offer a wide range of fiber cement panels with imitation of various types of surfaces. The products of companies from Japan and Italy are the most famous and demanded in the market of finishing materials.

Nichiha (Japan)

Products Nichiha characterized by a thickness range of 14 —35 mm The rate of thermal expansion during sharp fluctuations averages 0.1% per panel length. It is able to withstand 300 freezing cycles.

Thin panels marked “14 mm” are made without locks under the clamps, making it easy to mount on a flat wall surface.Since the weight of the panels marked “16 mm” and “18 mm” is greater, more reliable fastening with the help of clamps is required.

KMEW (Japan)

The manufacturer uses special coatings to protect the panels from moisture. During the manufacturing process of KMEW products, scanty cavities are created in the panel structure, providing high frost resistance and durability. In comparison with similar panels of other companies, KMEW products are distinguished by less weight.

A-Stone (Italy)

On the model of facade panels from A-Stone, the price is lower than that of other manufacturers. The Italian brand offers facade finishing materials that can withstand 150 freezing cycles. In addition, A-Stone panels can withstand more than 1000 hours of constant exposure to ultraviolet rays.

Installation of facade panels for plaster

Facing the building with stucco panels can be done with your own hands. Manufacturers provide detailed installation instructions.

The consistent implementation of all stages will allow you to successfully cope with the work.

Fiber cement board fastening

Facing with facade panels for plastering is possible on stone, brick, wood, concrete blocks, wood concrete. Preliminary putty and additional leveling of wall surfaces are not needed. The work is carried out according to the principle of building facades using a frame and allows you to use the space between the panel and the wall. To make the house warmer in the cold season, put heat-insulating materials in the gap.

To work, you will need:

- Bulgarian,

- level,

- screwdriver

- ruler

- markers

- fasteners

- profile or wooden beam.

The foundation and walls of the building support the weight of the panels without additional reinforcement.

The process of laying facade panels under the plaster includes:

- wall cleaning work;

- markup;

- fixing on the walls of the guiding structures of the frame at a distance of at least 60 cm from each other;

- installation of guides around the perimeter of the structure;

- work on laying panels with subsequent fixation - when fastening with screws and nails, hats are painted to the color of the panels;

- laying the upper bar.

Lay the panels with a gap and fill it with sealant. Thanks to the use of a special painted composition, the interpanel seams and fasteners are hidden. Sealing by this method allows you to reliably protect the walls from moisture, as with plastering.

Installation of panels for plaster of fiber cement 16 mm thick and more is performed using clamps.

Thermal panel mounting technology

Each manufacturer of facade thermal panels offers recommendations for the installation of products. Ask sellers about it or study information on the websites of the companies. See below for more tips:

- In the absence of glue of the recommended brand, use glue for external installation of a specific type of insulation, which is indicated on the package.

- It is desirable to fix the panels for plaster with standard dowels with a small head in the seam between the tiles, so as not to disturb the layer of lining.

- If there are many fastening points for dowels, then installation of panels without glue is possible.

Conclusion

Consideration of the types of panels with simulated plaster for building facades, popular brands, as well as installation technologies shows that their use in decoration is preferable to plastering. Decide which type of decoration material is more suitable, and proceed to decorate the house.

Before you start installing panels yourself, watch the video in this article and read the photo.