Plaster front Bolars

Facade stucco Bolars is a material of a Russian company that is recommended for use for exterior decoration of a building in order to protect the building base from the negative effects of the environment and improve the indoor microclimate. The coating also improves the appearance of the building, giving the surface a beautiful texture.

The content of the article

What is the material?

Facade plaster Bolars - a building product in the form of a dry powder for the preparation of a solution. The composition of the product contains substances that have moisture resistant properties, which makes it possible to use the material in rooms with high humidity and for outdoor decoration. The mixture also contains modifiers. These substances protect the surface from cracking. The composition also contains polymer additives that improve the technical characteristics of the product and increase the shelf life.

Advantages and disadvantages

Advantages of Bolars decorative plaster:

- frost resistance, the material is used even in harsh climates;

- resistance to temperature extremes - the product withstands changes from +50 to -600C without changing the technical characteristics;

- the appearance of the finish does not change under the influence of ultraviolet rays;

- moisture resistance;

- high adhesion to the building base;

- good elasticity and acceptable consistency, which facilitates the application of the material;

- lack of shrinkage;

- vapor permeability, which will provide air access to the construction base;

- unique self-leveling properties, thanks to which, after the composition dries, the surface becomes smooth and there are no defects on the basis.

Professional craftsmen did not find any flaws in the material.

Features of the tool

Bolars decorative plaster is used for decorating buildings outside and indoors inside at an air temperature of +5 to + 300C. Do not finish in cloudy, rainy or windy weather. In the presence of condensate on the surface, the material is poorly fixed. This will cause the finish to move away from the building base and will necessitate repeated repairs.

Specifications

Material Specifications:

- increased density - 1550-1659 kg / m3;

- solidification period - 3 days;

- the volume of water per kilogram of product is 200-230 ml;

- layer thickness - 3-20 mm;

- frost resistance - 50 cycles minimum;

- time for using the finished composition - 3 hours;

- compressive strength - 4 MPa;

- thermal conductivity - 0.4 W / mK.

Expense of funds

Cement or gypsum plaster Bolars have the same flow rate. The manufacturer indicates the exact data on the packaging. Consumption is 13-14 kg / m2.

Types of material

Types of plaster:

- Decorative plaster Bolars Bark beetle. The material is used to finish the building inside or outside. The tool is released in white, but the composition can be painted. The size of the fractions of the material is 1.5 mm, 2.5 mm, 3.5 mm. Plaster Bolars Bark beetle on the surface forms an interesting texture, similar to a tree spoiled by a bark beetle.

- Starting tool. The composition is used for roughing to level the surface and mask imperfections. Suitable for exterior and interior decoration.

- Lime-cement composition for blocks. The tool is used for gas silicate and gas and foam blocks.The material is also used for plastered, brick and concrete substrates before finishing.

- Gypsum plaster Bolars. The tool is based on gypsum. Moisture-resistant compounds are present in the composition, so the material is used for exterior decoration.

- Heat insulating agent. The composition is used to warm buildings from the inside and outside. Material that is applied over 60 mm thick replaces foam and similar products. After solidification, the craftsmen finish with any decorative composition.

- Pebble material. Such a product, as well as the bark beetle plaster, is used for the finishing of buildings. After solidification, the surface acquires a pebble texture.

Application area

Plaster decorative Bolars is used for the construction basis from stone and concrete. The tool is also recommended for use on brick and aerated concrete surfaces.

Cost

Low price is one of the advantages of the material. This applies to both the mixture for the starting finish, and for the finishing application. Plaster front Bolars, weighing 25 kg, costs about 230 rubles.

Surface preparation

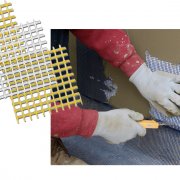

Preparation of the building foundation consists in removing the old coating, degreasing the surface and eliminating the defects. If large defects are found on the surface, then the cracks are filled with a solution (as in the photo below). Then the surface is cleaned and coated with a primer. The material is applied in two layers. After each treatment, a break is taken to dry the product.

Solution preparation

To prepare a solution with your own hands; you will need a clean bucket and industrial mixer. This tool can be replaced with a drill with a mixer nozzle. The proportions of water and material are indicated on the packaging. Algorithm for preparing the product:

- pour cold water in the bucket in the required amount;

- Pour the mixture slowly into the container, stirring the solution with a construction tool;

- Knead the product until the material acquires the consistency of thick sour cream;

- Leave the solution for 5 minutes and mix again.

For finishing work, first make a means for starting, and then for finishing.

Application Technique

Instructions for applying the solution:

- put the product on a spatula and distribute it on the wall;

- level the material and interrupt to dry the composition;

- clean the surface with sandpaper P 60 or P 80;

- apply the primer in two layers with a break for drying;

- put the finishing composition on the surface and level the surface;

- until completely solidified, but after loss of viscosity, treat the material with a polyurethane grater to give the texture of the bases;

- wait for the product to dry and stain.

The video in this article shows how to use the composition.

Domestic construction materials of the Bolars company are high-quality products with high technical characteristics.