Wall plastering machine: technology of work

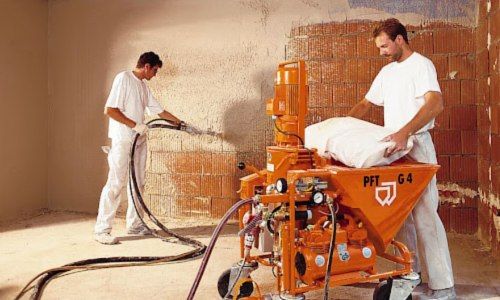

The plastering machine simplifies the finishing work as much as possible and reduces the time spent on this process. This technique can be used when applying the solution to walls and floors, it is universal.

To speed up the surface finish, a special plastering unit is used. With its help, you can prepare a quality solution and apply it to the surface. How to do this will tell the article.

The content of the article

Features of using a plastering machine

Plastering installation for coating is a good solution when repairing a room, regardless of the amount of work.

In addition to saving time, it has many other advantages:

- Great labor productivity, compared with manual work, it is about six times higher.

- Reduced financial costs for paying workers, with this method does not require the involvement of a large number of specialists.

- Higher quality and increased surface strength after coating. After machine plastering in compliance with the technology, additional operations are excluded, including grouting, brushing, and puttying.

- Significantly saved materials.

The disadvantages of the method:

- The need to purchase special equipment.

- The high price, therefore, it is not always rational to use the mechanical method.

The cost of the work depends on:

- The area of the treated surface.

- Type of solution and its price.

- The geometry of the room.

- The thickness of the stacked and leveled layer.

With mechanical plastering of walls, modern mixtures are used, which differ:

- Quick drying.

- High adhesion characteristics.

- Good heat and sound insulation properties.

- Vapor permeability.

With this method, the quality of the leveled surfaces is repeatedly increased and a more favorable indoor microclimate is created.

Using DIY plaster technology using a mechanized method, the process is carried out in several stages:

- Surfaces are cleaned of protruding elements, dirt, dust, greasy spots, glue are removed, their roughness and curvature are evaluated, beacons are mounted (see. Stucco beacon: types, purpose, installation), all angles are strengthened.

- The walls are treated with an anti-corrosion compound.

- The mixture is loaded into a plastering machine, where the dry components are mixed with water until a uniform consistency is obtained.

- When mechanically applying a plaster coating with a spray gun, the jet must be supplied strictly perpendicular to the walls.

- With spatulas and a rule, leveling is carried out, surpluses are redistributed, hard-to-reach places are worked out manually: angles are adjusted (see How to plaster corners: detailed instructions), joints, niches.

- Two hours later, after the set has set, grouting is performed to eliminate the smallest defects and give the surface a smoothness.

- After four days, under normal temperature conditions, the layer dries completely, you can perform the finish.

Tip: The presence of increased humidity increases the drying time of the solution to seven days. Do not rush to do decorative finishing until the surface completely dries, otherwise the quality of the repair will suffer.

The video in this article shows well all the nuances of mechanical wall decoration.

What mixes are used for plastering with a machine

When performing outdoor work, often for mechanical plastering of facades (see Stucco of the facade of the house, as a way of decorating it and extending the service life) and socles used, diluted in a special way, cement-sand mixture. For the mechanical finishing of internal walls and ceilings - gypsum-based compounds. Many ready-made solutions are suitable for manual and machine application.

The plastering of surfaces by machine is carried out by a special apparatus, which feeds under pressure, which creates a compressor, a solution to the wall with a fairly uniform layer, which allows you to:

- Save material.

- Provide better grip.

- The solution fills the smallest gaps and cracks.

- The content in the finished mixture of plasticizers and additives improves the quality and strength of the coating.

Equipment for mechanical application of plaster

Manufacturers to facilitate plaster release:

- Air hammer. The device of the machine is shown in the photo.

Such hoppers are equipped with several nozzles designed for soft and hard solutions. The composition of the unit for spreading the mixture includes:

- steel container for scooping up the composition;

- four nozzles through which the mixture is supplied;

- four air nozzles;

- holder tube with a valve mounted on it for supplying compressed air.

When working with stucco pneumatic shovels, special skills and special qualifications are not required.

- Air gun. This machine consists of:

- a short nozzle barrel, onto which several nozzles are screwed onto the thread, which provides a different degree of spraying of the solution;

- at the top of the cartouche gun there is a plastic or metal funnel-container with a volume of approximately 5 liters.

- a branch is made at the bottom of the handle through which the hose is connected to supply air from the compressor.

To use the composition of the plaster of different consistency, there are various nozzles for the equipment. In the projection gun, it is possible to regulate the flow of the mixture and air, which allows you to perform rough alignment of walls and decorative finishes, including textured spray.

- Plastering machines.

Units of domestic production for mechanical plaster differ from foreign ones in significant dimensions. Used for applying rough coat of plaster and putty.

For the preparation of solutions are taken:

- Lime.

- Cement.

- Gypsum.

Tip: To perform plastering in your home, you should purchase middle class products. They are more compact and adapted to work on them by one person.

The installation kit includes:

- A special pump with which you can cook, pump, spray and apply dry, pasty and other mixtures, with a grain fraction of up to two millimeters.

- Capacity for placement of water and dry mix. Here the solution mixes well, becomes loose, filled with oxygen.

In modern devices, the proportions of the mixture are correctly programmed, which allows you to get the correct consistency of the solution, providing material savings, high-quality and durable leveling layer. The finished plaster mortar is fed through any hose to any surface.

The use of special nozzles helps to create a stream of the necessary shape and size. The use of machines for applying plaster allows you to finish the wall much faster than doing it manually.

How to make your own simple wall plastering machine

The assembly instruction for the unit is quite simple:

Tip: A home-made unit for plastering walls is made according to the principle of operation of a gun - a spray gun operating from a compressor.

- The base of the unit is a fire extinguisher.

- The device is cut to obtain a capacity of approximately 4 liters.

- Inside, a tube with a nozzle with a diameter of 4 millimeters is inserted into the outlet opening with a diameter of 10 millimeters in the fire extinguisher; the distance from the nozzle to the outlet is up to 20 millimeters.

- Nozzles can be made with different diameters, from three to five millimeters.

After manufacturing, productivity is almost 55 seconds during processing of almost a square meter, while the flow rate of the solution is about 4 liters. The use of any fixture or machine for decorating the premises facilitates the process and reduces the time for its implementation.