Video instruction: plastering walls on lighthouses

Plaster is called a monolithic finishing layer applied to the surface of building envelopes and decorative structures in order to level them. When it is necessary to perform a screed on the walls of a large room, beacons are used as guides to bring the surface into a single plane.

Their use makes the work so easy that even an inexperienced person can cope with it with their own hands. What is the technology of wall plastering on lighthouses, you will learn by reading the theoretical material presented here. And to fix the information visually, the video in this article will help.

The content of the article

Rules for plastering

Before we tell you how to plaster walls with your own hands on lighthouses, we draw your attention to some technological nuances of this type of decoration. Its main regulation is the technological map 106-05 TC (2005).

This document is intended for personnel carrying out these works, it is guided by both designers and representatives of technical supervision:

- The map contains requirements for mortars and the quality of the plastered surface, gives recommendations on the organization of work, the use of tools and mechanization. For homegrown specialists, the official document, of course, is not a decree, but if malicious deviations from existing technologies are allowed, one can only dream of the proper quality of the screed on the walls of the house.

Video: “Stucco walls on lighthouses” - will, of course, give a practical idea of the process of applying and smoothing the stucco mortar, but theoretical knowledge has not bothered anyone. This gap is intended to fill our instruction.

Why do we need beacons

The quality of the plaster may vary, as the purpose of the premises is different. It is clear that the requirements for plastering a garage or a barn cannot be as stringent as for the alignment of walls in a living room.

Therefore, plaster is divided into three options:

- The lowest quality for plain plaster, since it plays a more protective role than a decorative one. Basements, temporary structures and utility rooms - this is where plaster is used, which consists of only two layers: spray and soil. Nakryvochnyh layers, which are designed to smooth the surface, are not here at all.

Note! Simple plastering can be done without beacons - in any case, the TC does not require this. There is no such requirement for improved stucco. In this case, their use is left to the discretion of the contractor - for example: if the surface has significant differences in marks. And only for high-quality plaster, lighthouse installation is a mandatory technological operation.

- The improved plaster also has a coating layer, which should be smoothed by a half-trick. Accordingly, the screed is obtained of higher quality. This type of finish is intended for leveling walls in production halls, house entrances, schools and hospitals. When decorating a garage, a bathhouse or a makeshift in the courtyard, improved plastering is also used.

- Regarding high quality screed, then it is performed in all residential premises, cultural buildings, shopping and entertainment centers.Such a screed consists of at least four layers: spray - one, soil - two, nakryvochny - one. The minimum thickness of all layers is 2 cm, but if necessary, there may be more.

Therefore, a card is a card, and you need to focus, first of all, on specific working conditions. No big difference, running exterior wall plaster by lighthouses, or alignment of the walls inside the house. Only the composition of the solution matters, and the technology for its application is similar, and worked out for decades to the smallest detail.

Preparing for plastering

The plastering process consists of a set of technological operations, the set of which depends on the expected quality of the screed. Two of them: preparation and hanging of surfaces, are carried out regardless of whether the plaster is simple or high-quality.

So:

- The meaning of the preparatory work is to ensure maximum adhesion of the solution to the base - and it must be durable. The presence on the walls of old plaster, which has long lost its astringent properties, cannot be considered a solid foundation, and therefore it must be removed.

- Paint must also be removed if it is applied directly to a concrete surface or masonry, for which special rinses or solvents are used. Moreover, you need to clean not only the paint, but also any other stains: soot, mold, rust, grease, efflorescence.

- The cleaning method is selected based on the composition of the paint layer or other substance - otherwise, in the contaminated area, the plaster will not adhere to the base. Dust is also an obstacle to good adhesion, so it is first cleaned. Then, if plastering is carried out indoors, wet cleaning is done, after which the surfaces are treated with a primer (see Primer walls and all for that matter).

A surface notch also applies to the preparatory process. Most often, a concrete surface is subjected to such preparation, since it is very smooth.

If you have to plaster the brickwork with filled seams, they are sampled before spraying, or rather, scratched. This is done before priming, carefully removing the influx of the solution and dust.

Hanging

The technology of plastering walls with or without lighthouses includes a mandatory operation - hanging. This term originates from the word "plumb", with which they check the vertical and horizontal plane of the wall. According to the result of this check, removable inventory or mortar marks are installed on the surface.

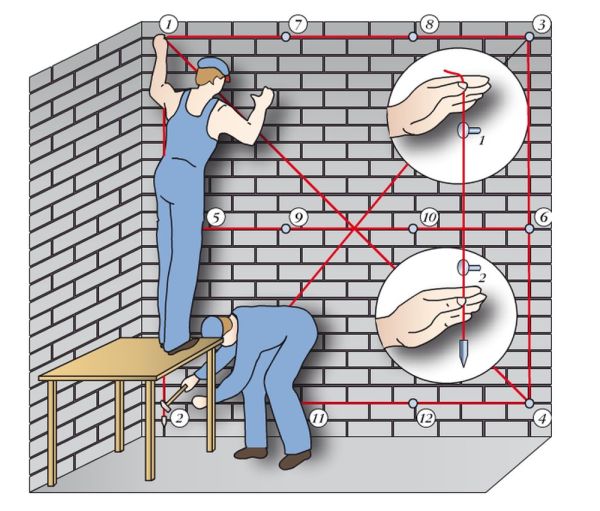

Let's comment on the suspension scheme:

- In a corner of the wall, about 30 cm below the ceiling, a nail is hammered. Between his hat and the wall should remain a distance corresponding to the thickness of the plaster layer. A plumb line is tied to this nail, which will help determine the position of the second nail hammered from below - its head should not go beyond the line of the cord.

- The second corner of the wall is similarly suspended, after which intermediate nails are hammered on both sides, in the middle, as shown in the photo below. Next, the plane of the entire wall is verified, for which the cords are pulled diagonally. They should not touch the surface of the wall, and if this happened, it means there is a bulge on it. Most often this happens with masonry.

- In such a situation, the hillock needs to be cut down. When this is not possible, the clogged nails must be pulled out so that the plane bounded by the cords extends forward, and the screed of normal thickness appears on the convex sections. For example, for improved plaster it is 1.5 cm - therefore, on concave sections of the wall, its layer will be at least 3 cm.

If you type in the search line “plaster the walls along the lighthouses of the video” and watch at least a couple of videos on this topic, even an ignorant person will easily understand the wisdom of the process. Well, for our part, we will also try to present this information compactly and intelligibly to you.

Stamps and lighthouses: installation

After the plane is aligned, intermediate nails are also driven horizontally. In principle, nails - this is the brand, which should be guided by the thickness of the solution. Only their hats create inconvenience when working with the rule, therefore, small areas of mortar are arranged around them.

- The nails are simply coated with a plaster mixture, and until it hardens, cut off the top of the tubercle flush with hats. The side faces are also cut: as a result, a solution mark is obtained in the form of a truncated pyramid, or a square with a side of three or four centimeters.

- The evenness of the future screed depends on the accuracy of the trim. If several more intermediate marks are made vertically between the main brands, a solution beacon will be obtained. Professional plasterers use reusable inventory stamps in their work. The removable mark is a dowel with a metal plate welded to it - it is easy to hammer it even into a concrete wall.

The use of inventory marks, as well as lighthouses, significantly saves time, which is especially valuable for a large amount of work. After applying a layer of soil, they are dismantled, the formed recesses are closed, and then they begin to finish alignment.

Beacon mortar

Lighthouses for plastering walls can be made of mortar, wooden slats, metal lighthouse profile. Mortar beacon is a strip with a width of 3.5-4 cm, which is subsequently embedded in a plaster layer.

The process of its device is quite simple:

- A rule is taken, the length of which is only 20 cm less than the height of the wall, and applied to the established stamps. It must be fixed: if two people are working, then one simply holds the tool, and the second fills the space between it and the wall with gypsum dough or cement mortar.

- It is inconvenient for one person to do this, so the rule can be fixed at the edges with bolts or nails. One way or another, the solution is squeezed under the rule with a spatula or spatula, and the excess is carefully cut off. In this case, the instrument remains as if frozen to the mortar strip.

When the strip hardens, it is slightly tapped and removed, and the voids formed in the lighthouses are closed and leveled with a trowel. After applying the second layer of plaster, mortar beacons are cut down, their locations are closed up, checking the flatness of the plane along the way, and eliminating inaccuracies.

Lighthouses

There are not only inventory brands, but also beacons. This means that they are not just removable, but also are inventory - that is, they can be used repeatedly. This option is used mainly by professionals who have to perform large volumes of work: they were dismantled on one wall - installed on the next wall.

- They are mounted quite quickly: after completing the suspension, control beacons are first hung in the corners. Under their fastening, special marks with a groove are provided, which are fixed to the wall with dowel nails, and their position is regulated by rotating the head of the self-tapping screw.

- After setting the normal level, the beacon is simply inserted into the grooves of the stamps - all this is clearly visible in the picture. To avoid deflection of the lighthouse, the same solution is placed under it, or a wedge is inserted. After the control beacons are aligned, the cords are pulled between them, and, guided by them, they mount intermediate strips. Since they are all attached mechanically, time is saved waiting for the solution to solidify.

- With the same success, as a removable beacon, you can use wooden slats that are installed on mortar marks. With the advent of fixed aluminum beacon strips, the task has been greatly simplified. This metal is not susceptible to corrosion, so such beacons can not be dismantled, but simply covered with a layer of plaster. Install them on mortar grades, or on a continuous strip of mortar applied along the entire length of the profile.

- For a better setting, ten percent of the binder: gypsum or cement is additionally added to the working solution. In places where recesses were discovered as a result of hanging, more solution is applied under the beacon. The correctness of its position is controlled by the level set along the lighthouse, and is adjusted by adding a solution, or squeezing out its excess.

The distance between two parallel beacons should be proportionate to the length of the rule used. Namely - if the rule is two meters, then the ideal distance will be 1.9 m. It is necessary that when leveling the mortar, it slightly goes beyond the boundaries of the planks.

Conclusion

From our article you learned what the role of stamps and lighthouses is in the process of plastering, what materials are used to install them, and how it is carried out. But it’s impossible to tell about everything right away.

- A video found on the request “how to plaster walls on video beacons” will give an idea of how to apply and grout the mortar, what tools may be needed for this, and how to use them correctly.

Get acquainted with other materials on this topic presented on our website - and we hope that they will help you cope with this responsible, and quite time-consuming work.