Mineral plaster and its application

Finishing work, both external and internal, are increasingly carried out using decorative plasters. Gypsum, cement, sand, lime, acrylic, crushed minerals are used for them. Mineral facade plaster It is found in different composition.

The content of the article

Benefits of Mineral Plaster

It includes particles:

- Granite.

- Marble chips.

- Lime.

- Light cement.

Note. These components give it high quality as a decorative finish.

A significant advantage of materials is their fast adhesion:

- Mineral plaster surpasses analogs in durability of connection with the bases.

- It dries for 1-2 days, and surface hardening occurs already in the first 20 minutes, so you need to work with it very quickly.

- The composition is applied in 1 layer, without corrections. If you do this in several steps, you get inflows and thickenings on the wall.

- Work will be ruined.

- Mineral decorative plaster - strong and strong material.

- She retains a flawless appearance for several years. Wall decoration will be durable, which means that new work does not need to spend money and effort.

- The porous structure of the surface partially absorbs moisture, which further strengthens the structure of the composition.

In the photo, you can consider the interior design using mineral plaster:

- Corridor decoration

- Classic Hallway

- Bright design of the hall

- Bathroom decoration

- Partial design

- Great idea for your home.

This type of finish is characterized by good heat and sound insulation, it passes air well, does not get damp and does not undergo the formation of fungal plaque.

Drywall Work

Especially often decorative mineral plaster is used on drywall:

- This is a perfectly flat surface on which the mixture lays well.

- This type of decoration is used to design individual elements of the wall - niches, cornices.

- He gives the appearance of the room a natural rude style, which is now fashionable.

- Internal walls can additionally be varnished to give. Shine and longer life.

In this case, less often will have to make cosmetic repairs.

Outdoor application

Due to its properties of resistance to moisture and temperature extremes, mineral decorative plaster is widely used to design the exterior facades of buildings:

- It is durable and beautiful wall decorationthat will last for many years.

- Separate the facade elements with plaster on minerals, or completely cover the entire surface.

Note. The composition is not exposed to fire, therefore, for fire-fighting purposes, it is good for them to decorate the walls and partitions from flammable materials - drywall, particleboard, wood.

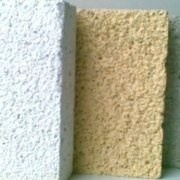

Mineral plasters have a rough surface with visible particles of mineral chips:

- They are used only for decorative purposes.

- Mixtures are superimposed on a leveled surface with eliminated swelling differences, with masked dents and crevices.

- If the wall is not thoroughly prepared, the flaws on it will be visible even more.

A thin layer of the mineral mixture cannot close them.

Finishing Application

Usually decorative mineral plaster is used to finish the wall:

- Its unusual texture creates an original style, does not require additional wallpaper or paint, lasts for a long time and does not require leaving.

- This is a practical and safe design of the interior walls of children's institutions and public buildings. In residential premises, mineral coating is used less frequently.

If you wish, such a surface can be coated with a matte paint or varnish:

- Coloring compounds are added to the mixture or a natural color is used.

- An unusual appearance of a pre-painted wall gives a thin layer of the mineral mixture.

- The color of the wall is preserved, but somewhat muffled and softened.

- Mineral inclusions ennoble the surface.

- If it is additionally covered with transparent varnish, then the original color of the wall will shine through even brighter.

- Depending on the type of filler, the plaster may be textured, rough or smooth.

- There are pebble, silky or grooved finishes.

Note. For many years, builders have been using facade plaster called “fur coat”. She is laid out in the correct geometric medallions or put in a strip around the perimeter of the house.

How to make mineral plaster yourself

If you have some skills in the construction business, you can try to finish the wall with your own hands without involving a specialist. The coating technique is not much different from conventional plastering.

Tip. Protective clothing should be prepared, since contact with the skin is undesirable.

Necessary materials and tools for work:

- When using a dry billet, it is necessary to have containers for mixing the composition with water.

- Mixer for preparing a uniform solution.

- Spatulas of different lengths and widths (seeConstruction spatula - types and differences).

- Steel grater (for applying the composition).

- Trowel.

- Soft plate to create a texture pattern.

- Beacons, duct tape, corner profiles.

- Reinforcing mesh.

Application Instructions:

- At first the walls are lined with rough plaster.

- Eliminate dents, traces of dowels, cracks and roughness.

- Particular attention should be paid to the clear shape of the corners.

- After the initial layer has completely dried, the wall is polished with an average size sandpaper and degreased.

Stage one

It is carried out in this way - a soft heat-insulating material must be strengthened with a reinforcing mesh:

- Initial plaster is then applied to it.

- For a good grip of formulations before the finish primed wall.

- Before starting work, it is necessary to calculate the amount of solution, since it is not stored and is applied in one layer.

- You need to know how much is needed per 1 m2.

Tip. Tools must be moistened with water during operation. If you bought ready-made plaster in the store, and it turned out to be very dense, you need to dilute it with water and mix thoroughly.

Stage Two

Inhomogeneous mass will drain. The consistency should be such that the solution adheres well to the spatula, but is soft. If the plaster is applied in a patterned manner, masking tape is glued along the edges of each element so that there is a clear border of color.

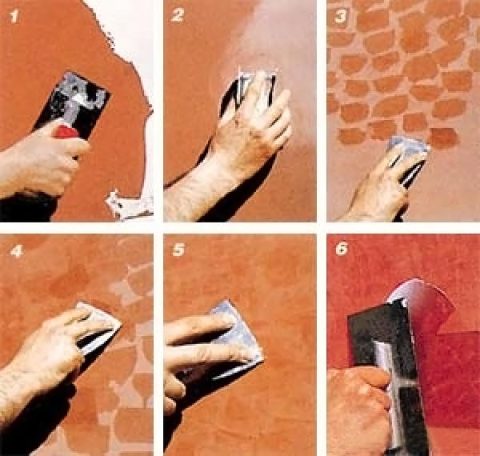

The mixture is applied by vertical movements, the angle between the spatula and the surface is not more than 15 degrees:

- First, a layer is applied by arbitrary movements, then they are aligned thinly and evenly.

- The coating thickness should not exceed the size of the filler particles. In the corners, profiles are fixed and the boundaries of the compounds are aligned with the mixture.

- Soft plaster allows you to apply any pattern or relief to a damp surface.

- This is done using a plastic grater with the desired pattern.

Note. For example, in order to obtain the “Bark beetle” relief, circular or vertical - horizontal movements are made with a plastic plate, leaving thin grooves.

Stage Three

Scotch tape is removed 15 minutes after applying the solution:

- On large areas of coverage, an electrical unit is used to apply the solution to the wall.

- But alignment is done manually. With this method, the finishing time is significantly reduced, but the quick hardening of the mortar requires masterful, precise alignment.

- The facade of the building plastered outside must be protected from dust and debris during the drying of the mortar. You can stretch a film or a fine mesh over it.

The video in this article will help you visualize the process of preparing and executing wall decoration.

Types of mixture

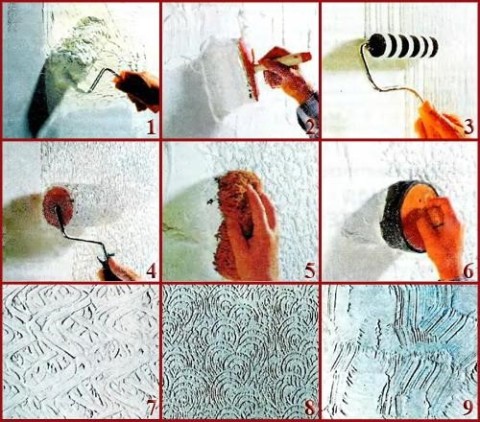

By type of structure, 3 types of finishes can be distinguished:

| Lamb (pebble) | A large interspersing of small granules gives a resemblance to the wool of a sheep. The mixture is applied exclusively in circular motions of one and a half. |

| Mineral plaster "Bark beetle" | It features a lower content of filler elements and is applied in more straight lines. |

| The method of applying "Fur Coat" is more often used for outdoor work | But if a fine-grained solution is used, then such a finish is also suitable for indoor. A flat tool is applied to an even layer of the applied mixture and is pulled away with a sharp movement. On the surface are sharp-angled tubercles similar to wet fur. |

| Venetian plaster | Imitates a marble covering. |

| Wet silk | Shiny finish and mica chips. |

Mortar consumption rates

It is necessary to take into account the size of the filler fraction:

- The larger it is, the thicker the layer of plaster.

- On the packaging of the finished store mix, this figure is slightly underestimated.

- That is, you need to purchase material with a small margin.

The table shows the consumption rates of plaster:

| Type of plaster | Granule cross section in mm | Consumption per 1 m2 in kg |

| Lamb | 2,5 | 3,5 |

| 3,5 | 4,9 | |

| Bark beetle | 1 | 2,5 |

| 2 | 5-6 | |

| 3 | 8-9 |

In conclusion: application areas

In the apartment, you can finish the walls with a rough texture in the hallway or bathroom. This coating is not afraid of moisture. In the building materials market you can find a wide variety of dry and ready-mixed mixtures for mineral plaster.

Note. One of them is decorative minerix plaster. This material is manufactured by Gelster.

Minerix decorative plaster is used for facade work for applying paint:

- Its feature is the ability to decorate the outer insulation layer.

- The basis for the mineral finish is reinforcing glue. Apply the final coat to a smooth, even wall.

- Minerix decorative plaster is also used on concrete, cement substrates.

- They are treated with a primer 2 times. The mixture is prepared in the usual way - by mixing 25 kg of dry powder and 5-5.5 liters of water.

Mineral stone plaster imitates natural tufa, limestone. It is used for outdoor applications, and is applied with a thicker layer of 100 mm. After complete hardening of the solution with a percussion instrument, the texture of the stone coating is formed.