Decorative plaster Kaparol for decoration

Kaparol company produces different types of decorative plaster, which allows you to transform the interior of any room. A wide range of materials for finishing satisfies the needs of the most demanding customers.

Decorative plaster Kaparol makes it possible to obtain the desired structure and texture of the surface on the wall, creating a unique pattern on it.

The content of the article

Coating features

The Kaparol plaster, due to its special structure and texture, gives the interior an attractive and unique appearance. For the manufacture of the material, the smallest particles of mineral raw materials are used, which gives the coating high strength and durability. The mixture, using a conventional roller, is quite easily applied to the wall surface with your own hands.

Advantages and disadvantages of the material are presented in the table:

| Benefits | disadvantages |

|

|

Manufacturers

Caparol's manufacturing company and its main office are located in Germany on the state of Hesse. However, almost 1/2 of the turnover falls on the countries of Europe and Asia, where subsidiaries of the company are formed with equity participation of local partners. Overseas Caparol products are available in more than 30 countries.

These include:

- Latvia - “Krūza” and “amurs.lv”.

- Lithuania - Caparol Lietuva, UAB.

- Belarus - “Discus”.

- "Kaparol Ukraine".

Silicone plaster

Kaparol decorative plaster produced by the company can be of different types.

This is a pasty mixture, which includes special additives, ready to use. Its color may be white or color. The coating provides excellent adhesion and vapor permeability.

Allows to form a relief texture on the surface. The material is perfect for finishing insulated facades.

The advantages of the composition:

- The surface is easy to clean.

- Weather resistant.

- Vapor permeability.

- Versatility in use.

- Easy to apply.

- It can be used for finishing mineral wool and polystyrene (seeHow is foam plastering done?).

Cons of silicate plaster:

- Low elasticity.

- You can not tint in saturated colors.

- High price.

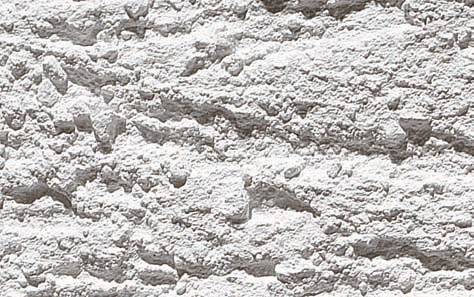

Samples of silicone plaster from Kaporol:

| Coating pattern | Features |

Structural plaster is made on the basis of silicone resin. Grain size 2 mm. Used as a finishing coat for:

Not applicable for surface finishes made of wood and plastic. | |

Decorative coating with the texture of the Lamb. It is used for finishing facades of buildings and walls in rooms. Index K stands for - “Fur coat” plaster with the texture of Lamb (seePlaster front Lamb - a practical "clothing" for your home) The grain size of the filler is indicated by the number after the K index and is 1.5 mm. Paint after application:

It is applied, as well as the previous structure. |

Silicate Stucco Caparol

The basis of the coating is potassium glass.

Benefits of coverage:

- High vapor permeability.

- Ecological cleanliness.

- Weather resistant.

- Almost odorless.

- Easy to apply.

Most of all, silicate coating is suitable for the restoration of ancient buildings and architectural monuments. Good compatibility with old building materials, allows you to purchase plaster for decoration of temples.

The disadvantage of silicate plasters is the limitation of the color range, if necessary, tint the coating. But the specially produced Caparol Amphisilan / Sylitol series absolutely satisfies the entire palette of historical facades.

Some examples of silicate plaster are presented in the table:

| Coating pattern | Features |

Not suitable for surface treatment:

Has all the properties Bark beetle plasters. | |

| White silicate paste. It has the properties of “trowel” plaster. Unsuitable for surfaces with varnish coating, efflorescence, for wood and plastic substrates. |

Acrylic facade plaster Kaparol

It has all the necessary qualities to obtain structural surfaces.

Coating Benefits:

- A wider selection of colors when tinting.

- Relatively lower cost.

- Practicality.

- Durability.

Acrylic plaster It has bright, saturated surface tones that cannot be created by other types of coatings.

Samples of Caparol Acrylic Plaster:

| Coating pattern | Features |

| Decorative bark beetle plaster with 1 mm grain reinforced with silicone. Used for outdoor use. | |

| Dispersion structural plaster reinforced with silicone, grain size 1.5 mm. It is used to smooth matte surfaces coated with dispersion paints and mineral coatings. Not suitable for plastics and wood. |

Mineral facade plasters

The basis of this type of plaster is:

- Lime.

- Cement.

- Marble chips.

The material goes on sale in a powdered dry mix. Before starting work, it is diluted with water to the required consistency, for which a special instruction is attached.

The grain size of the crumbs ranges from 0.5 to 5 mm. Grain sizes affect the magnitude of the surface relief and material consumption. Kaparol decorative plaster with large granules is best used for exterior decoration. Such a relief will look good from afar.

Tip: To finish the room inside, you should use plaster with a fine grain of filler.

The surface after plastering is considered finished after 3 weeks, and it can be painted no earlier than a month later.

Mineral coating has:

- High vapor permeability.

- Weather resistant.

- Moisture resistance.

Coating is recommended for decorating a house insulated with polystyrene foam or mineral wool.

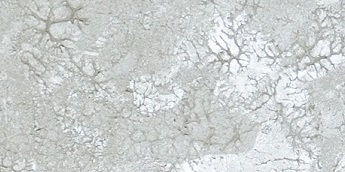

Kaparol mineral plaster samples:

| Coating pattern | Features |

Mineral dry mix made on the basis of lime and cement. Tinted mineral plasters may become slightly cloudy when dried, depending on atmospheric conditions.

| |

| A powder mixture used as a topcoat inside and outside a building. In order to avoid uneven tones, on the tinted plaster surface it is necessary to additionally apply a leveling layer of Capatect-SI-Fassadenfinish to the tone of the plaster. | |

| Mineral-matte plaster, is made on a cement-lime basis, with a natural white color, with the addition of mica. Tintable. | |

| Mineral dry plaster mix for troweling or smooth plastering of external surfaces. It is used for flat surfaces: slopes of door and window openings; basement surfaces. | |

| Dry lime-cement mixture for a matte finish. It is not used on surfaces with heights, wooden and plastic, and walls experiencing strong mechanical stress. |

Venetian plaster

This is the most luxurious decorative coating.

The main advantages of this material:

- You can cover the walls in rooms with high humidity.

- The material is odorless.

- It has environmental cleanliness.

The nuances of the application technology allow you to create a unique, unique pattern (see.DIY Venetian plaster: features of the work) It is quite difficult to work with such material, which requires a certain qualification of the master.

Examples of samples:

| Mineral coating for the ceiling and walls, consisting of marble dust, slaked lime and water. Calcino-Decor is perfect for decorating representative offices, reception rooms, conference rooms, hotels, banks and other premises for their high-quality decoration. | |

| A decorative filler mixture with a velvety effect and a metallic sheen for the design of indoor surfaces requiring high-quality wall and ceiling finishes. | |

| The coating is used to obtain smooth walls and ceilings with mirror gloss. Hard putty is based on dispersion for brilliant decoration of internal surfaces. |

Preparation for coating

Kaparol decorative plaster is applied according to the same principle as other similar textured coatings. The difference is an easier way to apply.

Tip: When finishing surfaces with Kaparol materials, you should use related materials that have the same brand.

The preparation of the walls is as follows:

- The base is cleaned until a smooth, clean, dry surface is obtained.

- Old enamel, paint or plaster is completely removed.

- The coating is cleaned with a dry or wet method.

- Mold surfaces are rinsed under pressure with a stream of water and then with a special Capatox compound.

- Dried well.

To prepare the material you need:

- Thoroughly mix the contents of the packaging with a special mixer with a low speed of the tool.

- If necessary, diluted with water to the required consistency:

- with manual application - a maximum of 2%;

- when spraying - no more than 5%.

Features of coating

For work, you can use a trowel or a special spray for plasters with fine grain.

- The composition is uniformly structured in a circle with a polyurethane or plastic spatula.

- Decorative grooved plaster should be distributed in a circle, in the vertical and horizontal direction.

- The choice of tool affects the surface contour, this requires the work to be done with a structuring tool.

- Depending on the grain size, the nozzle diameter for spraying is selected.

- The optimum pressure is from 0.3 to 0.4 MPa.

- Particular attention should be paid to uniform, without overlapping, application of the material when moving from one level to the next.

The use of natural pigments can cause slight variations in the shade of the color of decorative plaster.

Tip: When finishing surfaces, you should use material that was released in one batch.

Application technology

Detailing the composition of the walls shows the video in this article.

The work procedure includes:

- The whole mixture is thoroughly mixed with a stirrer. The main condition is that the speed of the device should not be high.

- The mixture must not be diluted.

- The surface is primed with a composition corresponding to the color of the plaster. In the absence of a mixture of the desired color, tinting is carried out.

- For application, it is better to use a roller with a short pile. It must first be soaked in a special composition, and then try to roll the tool in an empty place on the wall. This will provide better impregnation of the Caparol mixture.

- After a while, you should use a soft brush, which will create better drying conditions, and ensure a smooth working surface.

Kaparol brand plaster is applied to the surface in several stages:

- The mixture is applied evenly on the wall surface. Everyone chooses a material consumption independently. In places where the roller does not reach, a special brush is used.

- The coating is smoothed using a special brush with a soft surface. This stage is carried out 15 minutes after coating the main coating layer.

- After complete drying of the Kaparol coating, the surface acquires the final appearance, which will meet all the requirements.

An excellent solution for cladding building facades and walls is decorative coating Kaparol. The video tells in detail about all the stages of choosing a material for every taste, and then applying it to the surface. This is a resistant, durable, high-quality coating that will adorn any walls, including very old ones.