Stone stucco: material features and application methods

Stone plaster can be safely attributed to the most durable, expensive and time-consuming decorative coating, which has amazing beauty and expressiveness. Stone plaster differs from other finishing materials by its special composition and specific application method. Here we will talk about it later.

The content of the article

Material Features

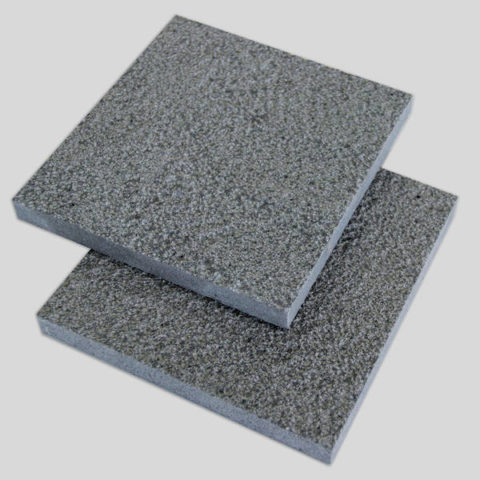

The name given type of plaster due to the coating that it forms after hardening. Its appearance is characterized by imitation of various rocks, when the decorative layer reproduces not only the shade and texture, but also the texture of the stone surface after cleavage.

Finding the differences between stone plaster and real stone panels is sometimes completely impossible.

A similar effect is achieved thanks to the crumb stone and other special ingredients.

Decorative stone plaster consists of the following components:

- As an internal filler, the use of natural marble is accepted (seeFacade stucco with marble chips: types, features, application methods), granite, tuff, lime crumbs. The reproduction of a particular rock depends on the crumb of which rock form part of the plaster. The volume fraction of crumbs is 3 parts of the total volume of the solution. Gloss is achieved by introducing mica in an amount reaching 2% of the volume of the mixture;

- Cement of white color or with a shade corresponding to the reproduced rock is used as an astringent. As for the volume fraction of cement, it is 1 part of the total volume of the mixture. To increase the mobility of the composition, you can add up to 20% of the lime test;

- As plasticizers, it is possible to add lime or stone flour, simulated rocks;

- To enhance the brightness of the shade, you can add a natural dye in the form of iron minium, manganese peroxide or ocher.

The unique effect of stone plaster can be achieved due to its special application method.

Attention! The fundamental difference is that in order to give the decorative finished look to the lime-cement compositions, they “work” with them when they have not yet hardened and have sufficient ductility. In contrast, stone plaster is “brought to mind" only after it has completely hardened, by cleaving the filler to obtain a sparkling texture of natural stone.

Material properties

Of the positive qualities of this finishing material, the following can be noted:

- A high degree of decorativeness and the wonderful beauty of the coating that imitates a real stone;

- The coating is strong and durable, due to the rigidity of the plaster mortar;

- The decorative coating is not afraid of the effects of the external environment in the form of direct sunlight, precipitation;

- The coating is resistant to open flame;

- The material is moisture resistant, therefore it can be used in rooms with a high level of humidity;

- The thickness of the applied plaster layer allows you to hide irregularities on the surface of the walls in the form of chips and cracks, therefore, does not require careful alignment of the base.

Of the disadvantages of this material, the following can be noted:

- The high price of this type of finishing material is associated with a large consumption of plaster composition per 1 sq. M, which amounts to 5 kg;

- The process of applying stone plaster is very complex and time-consuming. This is because the material is heavy and difficult to lay on the wall. Not having certain skills to create one layer the first time with your own hands will not work. The complexity is associated with the finishing of the solution after it hardens. To do this, you have to use a percussion instrument, as a result of which a lot of effort and time is expended;

- It is worth considering that the resulting layer is really very strong and durable (up to 30 years), so replacing the decorative layer will be very problematic.

The video in this article will tell you more about stone plaster.

Varieties of material

To give the particles of stone chips regular spherical shape, they must first be faceted. Due to this, the plaster composition is easier to lay and is safer in the sense that, due to the lack of sharp edges of the filler, there is less chance of cutting.

Depending on the size of the granules of stone chips, the material is divided into the following types:

| Name | Granule size mm |

| Fine stucco | No more than 0.5 |

| Fine stucco | 0,5 – 1 |

| Medium Plaster | 1,5 – 2 |

| Coarse plaster | 3 – 5 |

Fine texture plaster is used to create a uniform decorative layer. Fine plaster can be used to create a textured pattern. When using coarse plasters, you can get a coating with a pronounced play of the color of the inner filler.

Important! The amount of material consumed directly depends on the size of the internal filler. Accordingly, the labor cost of the work and its cost increases.

Use in the interior

To use this type of finishing material, there are no special restrictions when decorating the interior (seeWall decor in the interior and how to decorate the room) It can be used in any room and on any surface except for metal bases.

This is due to the fact that due to the water component of the stone plaster, metal corrosion can form. As for other surfaces - from concrete, brick, drywall and any cement surfaces, there is no restriction on the use of stone plaster.

In the minimalist living room, in the bathroom (seeDecorative plaster in the bathroom - types and methods of application) or in the kitchen you can use a textured uniform surface as a favorable background for furniture and accent details.

Using special tools, you can visualize masonry with its characteristic texture. The surface has an expressive relief, so it is not recommended to use it in the kitchen because of the susceptibility to the accumulation of contaminants. Such a decorative plane can become accented in the living room or bedroom.

You can use stone plaster with a mosaic structure, which is achieved through the use of multi-colored chips in the composition.Such a surface is characterized by high decorativeness and colorful mottled performance, so it is recommended to use it in the form of panels or accent spots.

The choice of style solutions

The stereotype that stone plaster is appropriate only in classical interiors is outdated.

Depending on the size of the textured filler, you can choose a covering for the interior in any style:

- In the classic interior the use of fine-grained homogeneous stone plaster to create a concise coating is appropriate;

- For the Baroque style larger stucco is suitable for decorating columns and arches, giving the interior an atmosphere of royal luxury;

- In the rooms decorated in the "Modern" style the coating should be shiny, but not distinguished by the relief of particles;

- Homogeneous smooth surface is suitable for the utilitarian "Techno" and the interior in the style of "Minimalism". For the Hi-tech style, you can use a shiny surface with a uniform color;

- A large filler of stone plaster will be a successful complement to natural and ethnic styles.

How to choose the color of stone plaster

Depending on the shade of the crumb in the composition of the plaster, its color is acquired. Focusing on the color of the filler, they select the colors of the dyes and cement - they enhance the shade of the filler, but do not determine it.

The stucco composition can be monochromatic, when when mixing it, a uniform shade of all components is achieved. To obtain a multi-color stucco composition, crumbs of different rock formations are used. Such a mixture is more difficult to apply to the wall, but thanks to it, an interesting colorful surface is obtained.

Important! Do not experiment with the finished stucco mixture. By changing its color with dye, you can change the shade of the cement component, but not crumbs.

Solution manufacturing

Ready dry mix requires only the presence of water and a construction mixer for mixing the solution. This can be done with one's own hands without special skills. Instructions on proportions and kneading techniques are given on the packaging of the mixture.

A mixture that is completely ready to work can also be found on sale. For example, stucco stone flower. However, it should be borne in mind that the price of the finished material is quite high.

Having the opportunity to purchase ready-made stone chips, the solution can be made at home.

Tip. The easiest way is to purchase a ready-made cement mixture, and add stone chips to it.

To make the mixture from scratch, you will need the following:

- Portland cement M400 is 5% of the volume;

- Mix it with marble sand with a size of fractions from 2 to 2.5 mm in an amount of 74% of the total volume;

- The solution requires the addition of 20% lime test (lime must be diluted with water, observing a proportion of 3: 1, and leave the batch for 24 hours);

- To get a shade of "Gray granite" or "Labradorite", manganese peroxide must be used as a coloring pigment;

- Water is added if necessary.

For interior decoration, the solution can be prepared as follows:

- White Portland cement is 8% of the volume;

- The production of lime dough is carried out in accordance with the above technology, its volume is 22%;

- As an internal filler, we use formaldehyde crumb (2 mm), in a volume of 60%;

- Manganese peroxide or chromium oxide can be used as a dye.

How to apply stone plaster

To obtain a smooth coating, the material is applied with a layer of 4 to 7 mm. The relief coating is obtained with a layer thickness of 15 to 25 mm. Using special tools, stone plaster is applied in several layers.

To put the composition on the wall, you need a spatula. Smooth the layer with a grater or a grater.

A specific tool for working with stone plaster is a hammer hammer with pyramidal teeth. It is used to crack hardened plaster and stone grains to obtain a special shine on the decorative surface.

Important! When working with a bushard, it must be held with two hands, and strike with the same force.

A trojan is also used for work - this is a kind of chisel whose tip is divided into three parts. This tool is used to crack the plaster at an angle (45 degrees). Different chipped surface texture depends on the size of the teeth of percussion instruments.

The method of applying plaster

Stone plaster is applied to the surface of the wall for a long and difficult time, and with a large grain size the process becomes even more time-consuming and lengthy. It will be difficult for a novice to do such a job.

The application of stone plaster is as follows:

- The starting layer of plaster is applied by spraying, throwing a composition on the wall with a particularly thick layer in places of unevenness and base defects. The thickness of the layer is taken to be 5 mm, so the consistency of the composition should resemble liquid sour cream. The first spray coating is used to increase adhesion between the material and the base. For the same purpose, the first layer is not leveled so that it can support the weight of the finish;

- The next layer is called a primer, and it is applied after 2 hours, when the spray hardens. You can verify this by clicking on it with your finger. In the absence of crumbling solution, work continues;

- Laying a thick primer layer is carried out with its smooth application, compaction and leveling with a trowel. When shells are formed, they must be immediately filled with a working solution and ironed;

- The third layer is nakryvochny. It hardens from 6 to 8 days, during which the plaster layer should be wetted with water from 3 to 6 times a day, depending on the air temperature. After that, the surface is left for another 2 days without wetting;

- Then a trial forging is performed.

Important! An insufficient degree of hardening of the plaster is evidenced by the fact that the crumb elements are crushed upon impact into the plaster composition. It is necessary to wait for such a state of the coating, when upon impact, the crumb can be split.

- The hardened cover is treated with percussion instruments (trojan, buchard) in such a way that, upon impact, the upper plaster layer breaks off and the filler grains break. A sign of a finished decorative surface is the presence of a special shine on its surface.

Create a textured surface

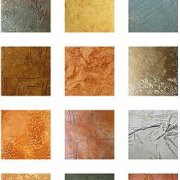

A decorative surface can be processed in various ways, using different ways of using tools, giving it a different relief and texture:

- When applying a notch with a bouchard, you can get the classic texture “Under the fur coat”. Depending on the size of the teeth of the tool, you can get a large or small surface relief;

- The effect of "grooves" or "hatching" is obtained using a trojan. The grooves are knocked out, focusing on the marking in the form of a stretched cord, the following notches should have a parallel arrangement;

- The texture “Checkers” looks like cells, each of which is processed using a trojan with the perpendicular direction of adjacent grooves;

- The “Strip” texture can be obtained by performing the surface of the wall in the form of separate stones, the borders of which must be knocked out with a chisel;

- The texture “Under the dunes” is obtained by chipping a thin layer of plaster coating with a chisel;

- The texture "Torn stone" is obtained by striking the chisel with a hammer at different angles. As a result, an uneven surface is formed with chips of different sizes;

- The texture “Clay sandstone” is obtained by chipping small pieces of plaster with a chisel;

- The simplest, most effective and time-consuming method is the technology of “stone chips without anvil”, when stone chips moistened and, if necessary, mixed with mica are poured onto a fresh cement mortar. After this, the stone chips should be pressed into the plastic surface of the mortar. To obtain shine, the hardened surface is cleaned of cement dust with a broom or brush;

- The surface relief texture can be imparted by etching it with 5-1% hydrochloric acid. Using a nail brush, small grooves are applied to the plaster layer, which are subsequently corroded by acid, giving them special expressiveness.

Important! When using a granite filler, the acid should be weaker from 3 to 5%. It must be applied with a brush or by spraying. When the etching process is completed, the remaining acid is washed off with water.