Facing with granite base: classic facade design

The basement is the structural part of the building that requires a particularly careful approach to its decoration. And here the main task is not so much decorative as the maximum protection of the foundation walls from the damaging effects of the environment.

In this article we will talk about what is the technology of facing the base with granite, and also consider what types of this stone are used for this.

The content of the article

Granite as a cladding for a plinth

For exterior wall finishes natural stone has been used for centuries. To make the building look solid and respectable, as well as the lining was durable, the most durable types of stone are used for facade work.

This is especially true when it comes to the base:

- Not all stones have the same properties: there are rocks with a porous structure that are not suitable for exterior cladding. Among the types of stone that are ideal for decorating facades, labradorite, travertine, gabbro, and marble are used.

- But granite for facing the base is used more often, and that's why. It's no secret that the most durable rocks used in construction are marble and granite.

They have almost the same physical and technical characteristics, but differ in appearance. - Marble has a richer texture and color palette. Accordingly, the price is much higher.

It is the desire for cost savings that often determines the choice of the buyer. Although granite is not much inferior to marble in aesthetic qualities, and is used to decorate buildings around the world.

- Most often, it is used for decoration of administrative and public buildings. Granite slabs, polished to a mirror sheen, and even correctly mounted, give any structure a monumentality and serve as long as it stands.

- The main thing is to correctly create a color scheme of the facade elements as a whole, because stone cladding is not subject to repair and replacement of plates. In a monolithic cladding, it is impossible to change anything without violating its integrity.

- The most valuable types of granite are black and red. One of the options for such a stone you see in the photo above.

The most affordable is gray granite. Of course, not its shade is an indicator of price, but the fact that gray granite is less durable.

Granite slabs for base trim have different costs depending on their size, thickness and method of surface treatment. Well, the quality of the decorative coating of the base will entirely depend on the skill of the person performing the finish.

Cladding

Installation of granite slabs is not the case when you can easily do the work yourself. Knowledge and experience are needed here, and no instruction can replace them.

When it comes to administrative or office buildings, construction teams and experienced craftsmen always work there:

- But there are also owners of private houses who want to make the basement of their house granite slabs. Whether they will try to do it themselves, or contact specialists, it will not hurt to watch the video in any case. But first of all, you need to decide on the choice of material.

Granite tile selection

AT basement trim rectangular granite tiles of small thickness, 300 * 600 and 400 * 600 mm in size, or tiles with a square section of 300 * 300 and 400 * 400 mm can be used.They are mainly used for low-rise buildings with a low base.

So:

- A more solid structure requires the same facing materials. In this case, stone slabs with sizes of 500 * 500 and 600 * 600 mm are used. By type of processing, all types of granite slabs are also different.

- Heat-treated granite has a pronounced texture and a rough anti-slip surface. These qualities are most in demand for flooring and staircase lining.

For facade work, either polished slabs or bichardized ones, that is, machined with a tool to give them characteristic natural chips, are better suited.

Installation

Like any other finish, the facing of foundation walls begins with the finish of their surface.

The degree of its preparation will depend on the installation method:

- But first, on the lower perimeter of the house you need to make a drainage pillow. It is a groove half a meter wide, 20 cm deep, which is covered with gravel.

A drainage trench will contribute to a better outflow of water. Over it then a blind area should be arranged. - Facing the base with granite, the technology of which provides for the gluing of elements, requires the most careful preparation. This includes: cleaning the surface of the old coating, the influx of mortar and dust, as well as its alignment.

This means that the surface of the basement walls must be plastered.

Note!

If you decide to clad the base of the old building, which was previously plastered, remove this layer, no matter how strong it seems. There may be imperceptible cracks in it, which will expand under the solid weight of the granite cladding.

- After the surface is cleaned, it must be impregnated with a primer. And it is best to use not ordinary concrete contact, but deep penetration formulations.

Such a primer will not only provide good adhesion of materials, but also make concrete or brick waterproof.

- Moreover, the processing of such compounds can be performed even on a wet surface. Once in the concrete, the soil crystallizes, displacing the existing moisture, and blocking its new supply.

This process, in fact, is the provision of external waterproofing of the basement of the basement. - For plastering any external surfaces, cement-based mixtures are used. This is important, because gypsum mortars are not suitable for facade work.

After the plaster is completely dry, it is necessary to make notches on it, with a step of 4-5 cm. Only after this can you begin to install granite tiles.

Advice! A process violation will cost you too much. Therefore, do not try to speed it up by starting to damp on wet plaster.

- So, first the lighthouses are fixed, that is, the lower and upper corner plates. Each of them must be strictly verified by level.

The quality of the entire lining will depend on how accurately these elements are laid. After the beacons are mounted, they begin laying the bottom row of plates, under which it is necessary to lay the board. - To ensure horizontalness, each subsequent row is laid on a cord, and checked with a plumb line and level. Seams are overwritten no earlier than a day after the end of installation.

It is better to take grouts on an epoxy basis, then the joints will be reliably protected from moisture and from chemical attack. - The adhesive method for laying granite cladding is good for tiles of the smallest size. But there are other ways of facing the base.

For example, granite slabs 600 * 600 * 50 in size have a rather impressive weight, and one adhesive solution is not enough to fix them. - In this case, it is required to perform anchoring of each element. And here the technology is completely different.Through each meter, small pieces of reinforcement are hammered into the wall so that its free end remains outside, and protrudes by about five centimeters.

- Metal corners are welded to these ends. A plaster grid is mounted on the wall surface and welded to the fixture.

Next, you need to mark and drill holes for anchor hooks. After their installation, slabs are hung on them, on which special cuts are made in the factory. - The space between the stove and the wall is filled with thick masonry mortar. Such a basement coating is a monolithic reinforced layer over which time will not be dominant.

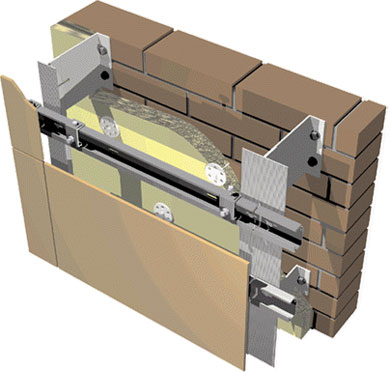

There is a frame method for installing granite slabs, it is mainly used when the basement requires insulation. In this case, medium-sized plates with a small thickness are used.

Their installation is carried out according to the technology of ventilated facades. Read materials on this topic: there are a lot of them on the Internet, including on our website.