The technology of facing the foundation or how to finish the base

There are many ways to beautifully finish the socles, but the choice of material for this purpose should be carried out, first of all, based on the design features of the foundation. Naturally, the installation process of one or another coating can be fundamentally different, because the facing of a screw foundation is not at all the same as the finishing of concrete walls of a basement.

In addition, the use of materials having a solid weight requires that a calculation is first performed on the foundation lining. In this article we will consider the features and nuances of finishing socles of various designs.

The content of the article

Types of foundation

Column and pile foundations

Structurally, these two types of foundations are fundamentally different, but they are united by the fact that in the end their basement looks approximately the same: a concrete grillage, which has supports at certain points.

So:

- Only in one case do piles play the role of supports, and in another do brick or concrete poles. Piles are usually used in unstable soils when the foundation needs to be deeply deepened.

For example, in the Far North, almost all construction is carried out on pile foundations. - The smaller and lighter the structure, the less effort is required to build the foundation. For small country houses, especially wooden, rather columnar foundation, buried to a meter and a half, while the length of reinforced concrete piles can reach twelve meters.

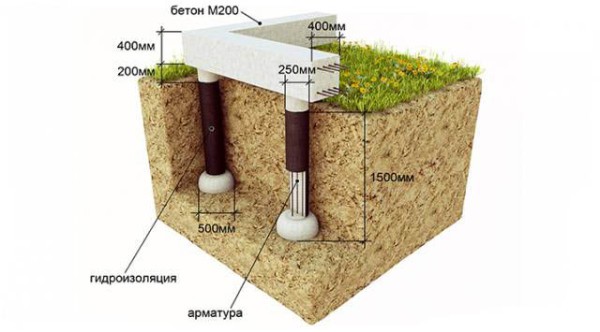

- Since the upper part of these structures is identical, then plinth trim the foundation will have the same technology. In the diagram given by us, it can be seen that the pile protrudes from the soil by 20 cm, and the height of the grillage is 40 cm. This is the distance that needs to be closed.

- The grillage is necessary in those cases when the walls of the house will be built of brick or blocks. If the house is wooden, instead of grillage, massive wooden beams can be laid, as in the photo below.

In this case, the piles protrude above the ground much more than twenty centimeters.

The lining of the columnar foundation differs from the lining of socles of other designs, in that there is no solid base necessary for the installation of a decorative coating. This very foundation must first be created, and not all types of finishes, in this case, will be available.

Brick base

One of the most time-consuming and expensive, but also the most durable options for installing a basement on a pile foundation is the construction of a brick base. Its essence is this: between the piles or pillars a kind of strip foundation is carried out, which will serve as a support for the brickwork.

So:

- Such a foundation for facing the base with bricks can be done when the pile heads are quite high above the ground and there is no concrete grillage. For example, if wooden house, a basement of brick will provide him with additional rigidity, and will take on part of the load.

- The technology for performing such a foundation differs from the usual supporting structure only in that it practically does not go deep. A shallow groove is cut between the pillars, the bottom of which is compacted with sand and covered with roofing felt.

Next, the formwork is made of unedged boards or plywood.

- The height of the shallow foundation made to support the basement wall can be as little as 20 cm.Part of the mortar is poured into the formwork, rammed, a metal reinforcing mesh is recessed into it, and then the rest of the concrete is added.

After gaining strength with concrete, you can begin to lay out the basement walls. - The minimum width of the foundation for the cladding is 30 cm, so the brickwork in one and a half bricks will fit perfectly on it. You can, of course, lay out a wall of ordinary building bricks, and then revet it with natural stone.

But this method of decoration will only increase its cost.

It is much easier to make brickwork from clinker or hyper-pressed brick: colored or embossed. It will be durable, very beautiful, and will not require additional surface decoration.

If the masonry does not exceed four to five rows of bricks, then even there will be no need to reinforce it.

Decorative base

If there is a grillage in the foundation design, there is simply no need to lay out the brick walls of the basement. And the distance of the indentation of the grillage from the ground is usually small.

In this case, it is easiest to make a decorative base, and there are two ways to do this.

So:

- The first method consists in the construction of a retaining wall from moisture-proof plywood, wood-polymer or cement-bonded particleboards. They are fixed both on wooden bars and on a metal profile, which, with the help of dowels and a perforator, is fixed to the grillage and posts.

- All of these materials are not afraid of moisture, and are an excellent base for stone or ceramic tiles. Further actions associated with laying a decorative coating will not be different from facing a brick or concrete wall.

Instructions and videos on this topic can always be found on the Internet.

- The second way to decorate the space under the grillage is the simplest, and the finish price, in the end, is lower. For the design of the foundation, basement siding is used with all kinds of imitations of masonry and brickwork, tiles, clinker tiles.

Siding panels are made of a wide variety of materials: aluminum, lightweight concrete, polymers. - All of them are equipped with lock connections, mounted on a crate, and the simplicity of the technology will make it possible to do the work even with a beginner. In short, this process is as follows.

A horizontal line is drawn from the top of the pile, along which a guide profile is fastened. - From it, with a step equal to half the height of the panel, the following crate belts are mounted. Then, from left to right, from the corner, vertical guides are mounted.

Their lower edge is buried in the ground by half a meter, and the upper one is attached to the grillage. The position of the elements of the crate is checked by level.

- If the distance between the ground and the grillage is small, no more than the height of one row of panels, vertical guides may not be needed. Especially if lightweight polypropylene panels will be mounted.

Note! When installing basement siding, it is necessary to remember the thermal expansion of materials, leave a small gap between the cladding elements, and also not tighten the screws self-tightening.

The nuances of installing siding panels on the crate may be different, depending on the design of their mounts.

Therefore, there is no single recipe for all occasions. As a rule, the panel mounting scheme is attached to the purchase of goods.

Base on a strip foundation

Strip foundations in low-rise housing are used in houses whose walls are built of brick or concrete blocks. They can be monolithic or prefabricated, and are deepened depending on the presence or absence ground floor, the dimensions of the building, the quality of the soil.

So:

- For the construction of the basement walls, concrete foundation blocks are used, or they are laid out of brick during the construction process. The height of the basement may vary, depending on how you intend to use it.

If there will be technical or residential premises, a garage, then the height of the floor will be at least 2.5 meters. - In some projects, the base only protrudes slightly above the ground. But there are also such constructions where the base is very high, and almost all is located above the ground.

Naturally, a slightly different approach is needed to its design. - Facing the strip foundation, in this case, is often performed using large-format plates made of natural stone or porcelain stoneware, facing bricks. Such heavy materials must necessarily be based on the foundation, and usually their application is provided for in the project.

- In this case, the width of the foundation for the cladding should be calculated in advance. The basement is necessarily insulated.

If this process will be carried out from the outside, then on the protruding part of the strip foundation should fit a layer of insulation and facing brick. And between them there should be an air gap of at least three centimeters. - According to building codes, a brick can protrude beyond the foundation one third of its width, but no more. Therefore, if you decide to improve the basement of the old house, and at the same time strengthen it, you will need to expand the foundation for the cladding.

To do this, the foundation must be dug up by making a groove of the required width along its perimeter.

- In principle, this work is carried out similarly to that which is carried out when the base was installed under a brick basement on a pile foundation. The width of the additional foundation of 20 cm, in this case, will be quite enough.

Think for yourself: insulation 4 cm + clearance 3-4 cm + brick 12 cm. When the concrete base is ready and gains strength, you can proceed to facing the basement. - But first you need to perform coating waterproofing. This applies to the foundation of the new house, and the old one.

Concrete and brick walls perfectly absorb moisture. To prevent this from happening, the surface of the basement walls is treated with waterproofing compounds.

To do this, use bitumen mastic, water glass, various penetrating soils of a new generation, such as Penetron, Hydroizol. - Then, after the soil layer dries, a heater is mounted on the walls. Great options for the basement will be plate materials: extruded polystyrene foam, vermiculite, foamglass.

All these materials are perfectly fixed by glue. - After the base is insulated, you can proceed to the brickwork. This process has its own nuances, and you need to know about them. For example, that every five rows of bricks, the masonry should be anchored, and this is done in different ways.

- If you want to perform the facing of the foundation, or the entire facade with bricks yourself, you can read about all the intricacies of erecting brickwork in articles on this topic, see master classes from experts.

- If you have a great desire to clad the base with natural stone, you can perform the insulation of the basement from the inside, and mount the stone by glue directly to the wall. This applies to rubble stone, slabs, large-format slabs made of natural stone and granite.

But coating waterproofing is also required in this case.

Almost any material can be used to finish the basement walls erected on a strip foundation: plaster, facade tile, mosaic, composite and siding panels. On our site there are detailed articles for each type of cladding.

Read, choose the appropriate option, try your hand, and we wish you success and successful design!