Facing the facade of a house with natural stone: some important tips

Facing facades with natural stone and today remains the most beautiful, and, of course, the most expensive finish. But, despite this, admirers of this natural material does not become smaller.

The price of a stone depends on its breed, and modern methods of processing it can significantly simplify and speed up the installation process, resulting in reduced cost of work. In this article, you will be offered instructions on the topic: “Facing facades with natural stone”, as well as a lot of other necessary information.

The content of the article

Stone Processing Methods

Not so long ago, the stone used for facing works was given the desired shape on hand-held machines. The advent of modern technology has eased this task, and the stone in the factory takes on convenient forms.

In addition to various variations of stone cutting, for aesthetic perception, surface treatment methods are also important, as a rule, emphasizing its natural structure.

| The appearance of the stone | The method of cutting and processing |

| The stone is cut in compliance with the exact geometric dimensions: bricks, tiles. | |

| Here, different breeds of stone can be mixed, or different cutting options. | |

| The stone is cut into rectangles, but their sizes can be different. | |

| The front side of the stone has characteristic chips, while the back side is sawn. The shape of the stone, in this case, can be different, respectively, and facade cladding natural stone will vary significantly in appearance. | |

| The name of this type of processing speaks for itself: the stone is cut into narrow long strips. | |

| This type of stone has a square or rectangular section, with rounded edges. Most often used for sidewalks or floors, but the basement, lined with paving stones, also looks great. | |

| This type of processing is done manually. The edges of the tiles are chipped to obtain a relief surface. | |

| Bucharding is not a cutting method, but roughening a surface. | |

| Mechanical processing of stone, which allows to obtain rounded shapes or the effect of aging | |

| Large solid layers of stone. Slabs are used mainly for interior work. They can also be seen in the design of monumental public buildings with a high base. | |

| Tile of irregular shape, which, in principle, is not processed in any way. It is formed in nature from layers of compressed sand. |

So:

- The method of cutting the stone, as well as the option of processing its surface, affect the aesthetics of the facade. As with any design, shape and color also matter.

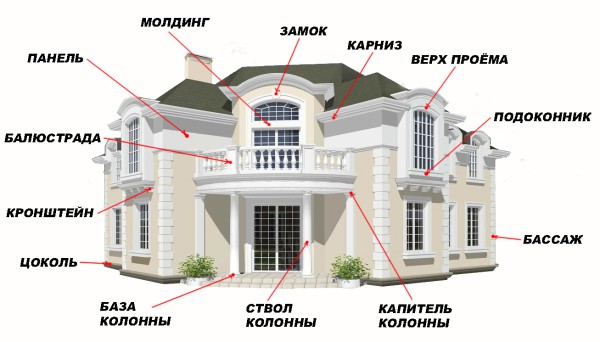

In the designed buildings, facing with natural stone facades is performed using curly elements, which you can see in the photo below. Without them, the exterior of the house will not get a finished look.

- Naturally, these parts are made to order, depending on the architectural features of the building. They can also be used if the walls themselves are not finished with stone, but with plaster. Actually, we see this option in the above diagram.

- To so clad a house, one desire is not enough - you need to order a design project for facade work.

Only then will it be clear how much material is needed for wall decorationhow many and what decorative elements are required to order. The selection of shades and options for combining stone are also being worked out at the design stage.

- Stone cladding always looks solid and respectable, and when observing the installation technology, it serves as much as the building itself is operated. Usually, exterior wall decoration Natural stone buildings are produced with the participation of specialists.

If this is a mansion with complex architectural forms, having many facade elements, it will be difficult for an ignorant person to understand the project. With your own hands you can perform only the simplest facing with a small format stone.

The intricacies of this work will be discussed in the next part of our article.

All you need to know when getting started

According to SNIP II * 22 * 81, the facade is lined with natural stone on the walls already erected. Roofing should also be completed, and, preferably, give the building time to shrink and relieve masonry stress.

So:

- This period varies between 3-6 months, you need to focus on the season. If the construction of the house is completed in the fall, it will be most logical to start exterior cladding in late spring, when night temperatures will also be positive.

In winter, it is better to do interior decorating. - If the facade will be finished according to the project, all possible information should be indicated in it.

Firstly, this is information about the stone itself: rock, deposit, size, texture of the front surface. Secondly, the project should have an exact specification of all architectural elements, embedded parts and fixtures for them.

- The minimum thickness of the plates, and their dimensions, are governed by building codes for each rock type. For example, travertine may have a thickness of 10.5 mm; volcanic tuff and hard rocks (granite, marble) 30 mm.

But the thickness of the facing stone from soft, porous rocks, such as: dolomite, limestone, shell rock, should not be less than 40 mm.

As for the format, the maximum size of the plates corresponds to 600 * 600 mm. This is the European standard used for the manufacture of facing materials that are mounted according to the system. ventilated facades.

This option can be called office, and in private construction is practically not used.

Adhesive solution

All backward variations of the stone are mounted by the adhesive method: in buildings whose height does not exceed five meters only in mortar, in other cases: in mortar and flexible joints. The brand of solution used must be at least M100.

So:

- If you do it according to the rules, the composition should be as follows: 1 part of cement M300; 0.1 part lime; 2.5 parts of sand. The higher the grade of cement, the greater the proportion of the remaining ingredients.

The sand fraction should be in the range of 0.5-1 mm. A small amount of lime is added to increase the plasticity of the solution and increase its astringency. - For the same purpose, plasticizers are introduced into the composition of the finished solution, which today can be bought at any hardware store. They are sold in plastic containers, with a capacity of 1-5 liters, and their proportion in the solution is usually 1 l / 100 kg of cement.

It makes sense to mix such a solution when the team is working, and it will be quickly developed. For independent work, it is better to purchase a dry adhesive mixture in bags.

Simple and convenient: water is added in a certain ratio, and the solution is ready - you do not need to measure the right amount of ingredients for each batch. This will simplify the work, and save from a possible miscalculation, for example: they forgot to add something.

Stone laying

Before proceeding with the installation of the stone, the surface should be properly prepared.All communication work, the production of which can contribute to damage to the cladding, must be completed before finishing.

The plane of the walls is verified using the level, and if there is such a need, they are leveled - that is, the sealing of potholes and cracks.

So:

- The base must be primed. If the stone is massive, notches are made on the surface or a fiberglass mesh is mounted. When using small-format stone, with the cutting type: “mix”, “noodles”, brick tiles, you can do without it.

- Before the stone is glued to the wall, it is necessary to wash off the dust and dry it. The grout mixture is mixed in parallel with the preparation of the adhesive solution, since the technology of the stone cladding involves sealing the joints immediately after gluing the stone.

- To avoid slipping of the cladding, the first row of tiles should rest on a rigid base. For this, a steel corner, or an aluminum L-shaped profile, the shelf of which will serve as a support for the stone, is mounted on the lower perimeter.

- The order of further actions is as follows: glue is applied to the back of the stone, and a relief is made with a notched trowel. The stone is applied to the base, slightly rocking and pressing tightly - this way the excess solution is expelled. They are picked up with a spatula, and the same is done with the next cladding element.

- After rubbing the joint between the already glued elements, you can continue the further lining. For clarity, before starting work it will be useful to watch the video, because unforeseen difficulties may arise.

If the stone has the exact dimensions, there are usually no problems. But there are options with a combined format, when you have to select stones according to the configuration.

- In this case, first the selection and fitting of stones is carried out, grinding of their edges is carried out. The ends and beds of each element are customized, and only then they are installed. If you have to hold onto a polished stone, after installation, its perimeter is sealed with masking tape, and the chipped edges are coated with clay.

- Only after that the joints are grouted. At the end of the work, the stone cladding is cleaned and washed.

The surface of a stone having a porous structure must be treated with hydrophobic impregnation. If this is not done, after a couple of years some sections of the cladding may grow with moss.

Water repellent forms a film in the surface layers, which closes the pores of the stone, preventing the absorption of moisture, and allows you to permanently maintain the elegant appearance of the cladding.