What is better laminate or linoleum

It is better for family members to agree on key components of the future interior “on the shore”, that is, in advance. The most acute question before. repair family tips: lay a laminate or linoleum on the floor. Young people vote for a laminate that looks more impressive, the older generation counters by the practicality of linoleum, which is not afraid of water, friends and acquaintances make a welter by statements like, "and we put linoleum under the laminate." Anticipating the questions, we answer: yes, you can lay the laminate on linoleum, and why this is done, we will tell a little later. But laying laminate flooring on linoleum is not the central question of this article, first of all, it is about the result of the “laminate versus linoleum” fight, when you need to choose one thing. Sit back and bet on the winner.

The content of the article

Laminate

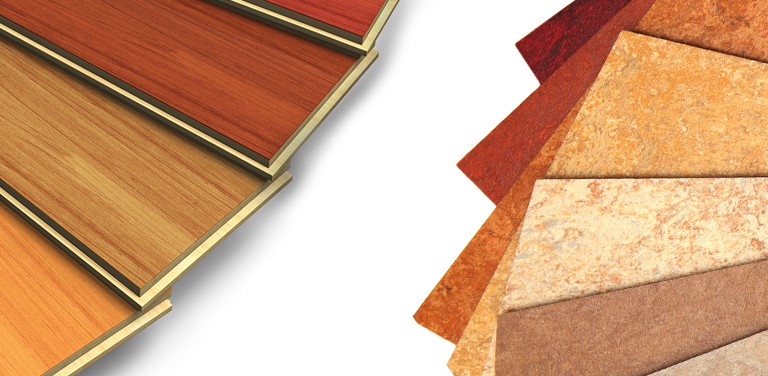

Both linoleum and laminates are presented on the market countless models with different performance characteristics. So choosing linoleum or laminate is not such a simple matter, for this you will have to figure out what they are and how they differ. And first of all, what are they.

From the name of the laminate it follows that something is laminated. In our case, it is a dense fiberboard or chipboard, coated on top with a decorative layer of specially processed furniture foil or paper, imitating a certain pattern (the popular one is natural wood, but stone, metal, and even leather are also found). And the upper laminating layer consists of a polymer resin (acrylic and melamine are used), converted into a thin, durable film. For the most wear-resistant samples, the thickness of this protective film reaches 0.1 cm. Under the fiberboard or chipboard, at the very bottom of the structure, there is kraft paper impregnated with resins or phenol, which protects from moisture.

Laminate Classes

In 1999, the European Union developed the EN 13329 standard, which provides for 18 tests of a laminate sample. Based on the results of the tests, the model is assigned a two-digit number indicating the wear resistance class.

Laminate flooring, in which the first in the two-digit number of the marking is the number 2 (21, 22, 23), are intended for use at home. Such a laminate is inexpensive (compared with another laminate, not with linoleum), designed for 5-6 years of service. But in our country it is not for sale, so we exclude the household laminate from the comparison and pay attention to the laminated floor coverings, originally designed for commercial premises. This gender will serve at home for 10 and 20 years. It is marked with a two-digit number starting with the three: 31, 32, 33, 34. With the addition of each next unit, the load on which the laminate is designed increases. The 31st class is considered the most popular for apartments, 32 and 33 are in slightly less demand due to the high price. The most expensive class 34 laminate in everyday life is rarely used because of the inappropriateness of the cost of it. The service life of a commercial laminate depends not only on the class, but also on the manufacturer. For models assigned to the same class, different manufacturers give guarantees for different periods.

Appearance

Laminate is supplied in boxes in which sheets from 0.7 to 1.1 cm thick are laid (in the household planks), from a meter to one and a half lengths and about 20 cm wide.Each “plank” of the most popular type of laminate has spikes and grooves at the edges that join them to each other (collectively, the design is called a click lock). Such a laminate is not attached to the subfloor, and the resulting coating is called floating. There is also such a laminate flooring that is fixed to the floor (substrate) with glue.

Manufacturers began to offer laminate flooring as an alternative for owners who dream of parquet, which they cannot afford. Therefore, initially the laminate was outwardly called to imitate the tree as realistically as possible, which corresponds to shades of brown. But as the market developed, new models of all kinds of colors appeared with imitation of other natural materials.

But laminated wood look remains an ageless classic. Moreover, this classic version has subspecies. On a natural laminate, a layer of varnish of a minimum thickness is applied and does not catch the eye, so the coating resembles an ordinary tree. Glossy laminate shines similar to varnished wood, since the varnish on it is not only noticeable, but also emphasized, exaggerated. The appearance of the matte finish creates an association with natural parquet treated with drying oil. The aged laminate looks “older” due to dark shades and special visual effects, the texture looks like untreated wood, waxed looks like waxed parquet, with a characteristic dull sheen.

Linoleum

Linoleum is a flexible roll material, in contrast to hard laminate sheets assembled as a puzzle. Each type of linoleum is made from its own set of components, let us consider in more detail which linoleum makes sense to compare the laminate with.

Materials for the manufacture

All linoleum on the market can be divided into 2 large groups: natural (also called marmoleum with the light hand of one of the manufacturers) and synthetic (which linoleum is not in fact and received this name only for external similarity). Natural linoleum is a jute substrate on which a mixture of cork or wood flour, linseed oil, wood resin and coloring pigments from natural materials is applied. Such linoleum is environmentally friendly, retains its original appearance for years, has antistatic and antibacterial properties. Of course, a democratic artificial laminate can not stand comparison with an elite marmoleum, so the choice of "laminate or linoleum" implies synthetic linoleum.

Types of artificial linoleum were named after the main component. Currently on the market are represented: polyvinyl chloride, (alkyd) glyphthalic (alkyd), rubber and colloxylin.

Alkyd linoleum is not chosen for residential premises due to increased fragility and the risk of cracking. After some time, rubber begins to evaporate substances harmful to people, therefore it is not completely safe and is not suitable for an apartment. The problem of an elastic colloxylin coating is an increased flammability and reaction to household chemicals. For this reason, the third type for the house is not used.

Every year, thousands of Russians opt for PVC coating. In favor of polyvinylchloride linoleum, moisture and wear resistance, the absence of negative reactions to temperature extremes and chemicals used in household use are evidence. It does not require extreme caution in laying, like alkyd. Not harmful to health, like rubber. And it complies with fire safety standards, unlike colloxylin. That is why we will carry out the final comparison of the laminate against linoleum, implying PVC linoleum.

PVC linoleum production technology

Polyvinyl chloride coatings are divided into homogeneous (single layer) and heterogeneous (containing up to 6 layers).These types are distinguished by their appearance, operational characteristics, and, of course, the manufacturing method.

Homogeneous linoleum is very durable and undergoes restoration if necessary, as it is painted over the entire depth and looks as before, even having lost up to 20% of the thickness. It is not recommended to grind more during restoration, so that the coating does not lose its positive properties. A single-layer coating does not imply a foundation, which gives subtlety and lightness, but the choice of colors is rather poor compared to the heterogeneous look, in which the design contains only one intermediate layer. One or more layers of protection are applied to it (the more, the more expensive the finished product). The base, located under the layer with the pattern, is a substrate of foamed polymer or felt, and the layers are bonded to each other with fiberglass.

It is worth noting that homogeneous single-layer linoleum is more often used in public places, that is, for commercial purposes. While heterogeneous flooring is used in everyday life, in homes and apartments. In the next paragraph, we will consider in more detail how the coatings differ in the scope.

Classification of linoleum by appointment

European manufacturers at the end of the last century began marking linoleum models with double-digit numbers, indicating the wear resistance class of the material. Which class the coating belongs to is determined by the classification EN 685, which has been used in our country since 1995. The standard regulates the tests to which the specimen is subjected, and describes the loads that linoleum can be classified without damage as it belongs to a particular wear resistance class.

Classes beginning with the numbers 2 (21, 22, 23, 24) are considered suitable in residential premises, the coating is called household. In office rooms and offices it is recommended to lay linoleum from 31 to 34 classes, with 31 and 32 called semi-commercial, and 33 and 34 commercial. In industrial premises with increased requirements for wear resistance, 4 1, 42 and 43 (highest) classes are used. The larger the second digit in the class designation, the more intensively the load withstand the coating.

Comparison of materials by basic parameters

Based on the above information about popular floor coverings - laminate and PVC linoleum - we compare them in terms of indicators that owners first of all pay attention to.

Which of the coatings has better sound and heat insulation is largely determined by the material and thickness of the substrate on which the decorative layer of the floor structure is mounted. Under the laminate, it is necessary to put a substrate, and a dense and thick substrate significantly increases the soundproofing properties of this coating, which practically does not absorb sounds. When laying linoleum on your own, it is easy to do without a substrate, but for warming it is an important element. Thus, according to this characteristic, it is difficult to single out one of the coatings, since the result depends not only on them, but ceteris paribus linoleum will win.

From an environmental point of view, laminate is the leader. Both coatings, if properly certified, are safe in everyday life during operation, but linoleum often causes allergies. In addition, it is more difficult and unpleasant to dispose of obsolete linoleum. Laminate burns quickly, without releasing hazardous substances.

Another aspect of coating safety is the fireman. In case of fire, both types of coating will light up, but linoleum is faster and more intense.

A noticeable difference is the moisture resistance of linoleum is much higher. Moreover, this is not only about accidental flooding, in which linoleum is not only not affected, but even retain a certain amount of water. And the laminate, by the way, just goes bad and lets the water pass on. Even with the usual wet cleaning, you should carefully wipe the laminate with a damp, wrung out mop or rag, avoiding the appearance of puddles.That is, water should not flow from a rag. Linoleum does not care about this test.

As for resistance to mechanical damage, disputes between the laminate and linoleum cannot be resolved without knowing their class. At first glance it will seem that a hard laminate is stronger and more resistant than soft flexible linoleum. But if the PVC coating belongs, say, to 33 or 34 class, then he is not afraid of either furniture legs, falling objects, or heels of shoes. Linoleum in this case will withstand the load no worse than a laminate.

The nuance is that if, nevertheless, the load exceeds the permissible limit and the polyvinyl chloride linoleum gets damaged, then the layer must be completely changed (unless it is a homogeneous coating that can be restored). And in the case of laminate flooring it is easier - only damaged sheets are replaced.

Laminate is more expensive than linoleum, if you compare the average price categories for both materials. And decorate the interior for less time, because the service life is shorter. From the point of view of economy, the laminate against linoleum has no chance.

It is easier to bring boxes with laminate sheets to your home than a roll of PVC coating, but installing both coatings is quite simple. The difference in installation is that under the laminate you do not need to carefully close up the defects of the subfloor, but you will have to level the surface until there is no slope and differences. Linoleum, on the contrary, is laid on a slope. The main thing is that there should be no cracks, no potholes, no chips. In your specific case, the coating will win, the installation of which will require less additional effort.

Finally, the look. The question is whether the laminate or linoleum looks more impressive, rarely causes disagreement. Here, the laminate is one step ahead, no matter what high-tech and fashionable models this season may offer manufacturers of polyvinyl chloride coatings.

In the end, only the answer to the question remained, what determines the laying of the laminate on linoleum. Why in some cases the old coating is not dismantled, but left as the basis for the new. This method is possible if the old linoleum is not severely damaged, and saves time on the preparation of the subfloor and money on the purchase of additional materials. And the new flooring receives an additional layer of heat and sound insulation at the base.