How to fix corrugated board on the wall: consider in detail

I welcome the team of the site Finishing-expert.ru. My name is Sergey, and I have this question, more precisely a few.

- Question 1: How to fix the corrugated board on the wall, or rather, is interested in what kind of fasteners can this procedure be performed correctly?

- Question 2: Is it mandatory to make a counter-grill?

- Question 3: Do I need to somehow process the walls before closing them?

- Question 4: Does the form of corrugated board affect anything? Still have not decided on the choice.

Thanks in advance!

The content of the article

The answers

Let's answer all the questions in order, as they were asked.

Answer 1

Structures from corrugated board and metal tiles are considered one of the lightest. They differ from each other in form and nothing more. The corrugated board is notable for the fact that its wavy shape fits perfectly for cladding building facades, which can’t be said about his "brother".

Due to the fact that the corrugated board is not a heavy material, it does not heavily load the supporting rafters on the roof, and the crate assembled under it for mounting on the wall. Therefore, the walls of the house from corrugated board are made easily, and their final cost will be low.

Due to this property, the technology of laying corrugated board on the walls recommends fixing metal sheets using self-tapping screws (self-tapping screws) without first preparing holes, or hexagonal screws with a substrate in the form of a rubber washer.

Attention! In no case can you install corrugated board with nails.

The installation procedure is as follows:

- We get sheets no less than the height of the surface to be trimmed. So you get rid of transverse seams and simplify your installation.

- If it was not possible to buy sheets of the desired length, then lay the corrugated board in order, with a minimum overlap of 8 centimeters. In this case, you need to start from the bottom rows.

- Decking is fixed in places of contact of the lower parts of the wave to the crate frame.

- When fixing the sheet to the extreme levels of the crate, sheets need to be attached in each recess, and on intermediate belts - fixing through one recess is permissible.

- Fasteners in the longitudinal joints are mounted at a distance of no more than 5 centimeters.

When working with a sheet, the use of electric welding and gas cutting is not allowed. It is also forbidden to make holes in profiled sheets in a similar way.

Laying corrugated board on the wall on the screws is performed using an electric drill or a screwdriver at medium speed. Be careful not to over tighten the rubber bands on the hex screws. The process of correct fixing is shown in the video in this article.

Answer 2

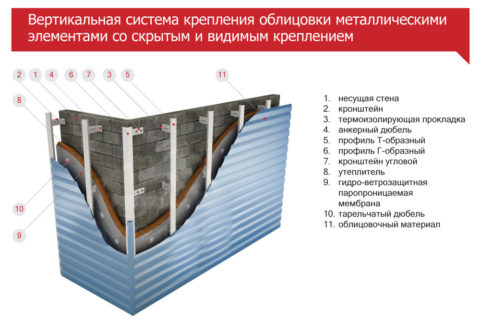

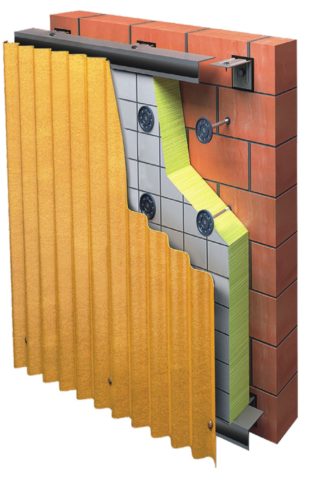

The answer to this question depends on what material the frame is assembled from. Why do we need a counter grill? The counter belts of the crates are mounted in order to provide a ventilation gap for waterproofing, that is, simply, it allows the film to dry out after contact with moisture, and also erodes all the accumulated condensate on the back of the metal.

The waterproofing is mounted when you insulate the internal space of the frame, for example, with mineral wool, which does not tolerate moisture:

- How is the process of building a wooden crate? First, the bars are vertically packed on the walls (if it is not provided that the corrugated board will be mounted horizontally).

- Then the space between them is filled with insulation.

- A waterproofing film is packed on top of the timber.

- Then, parallel to the beam, a lath made of a thin rail is mounted, which will firmly press the insulation.

- Then, perpendicular to the crate, a counter-crate is placed in increments of 50 centimeters.

If a metal profile frame is used, then a counter-lattice is not needed, since the frame belts are installed on bracketsthat are separated from the wall by the desired distance. The insulation and waterproofing agent are fixed on the so-called “fungi”.

Answer 3

If the facade is insulated, surface treatment is carried out with a deep penetration primer. This is done in order to improve adhesion to the base of the adhesive layer on which the insulation boards are mounted.

If the facade is insulated, then the base does not need any treatment. The walls will be protected from direct moisture by corrugated board.

Answer 4

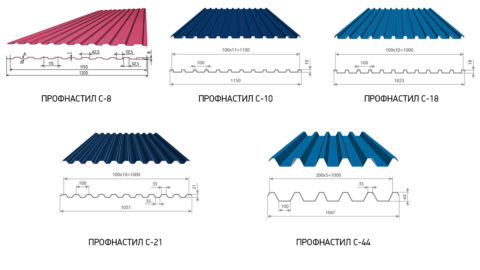

There is a specific instruction for determining the type of corrugated board. For cladding walls and roofs with a small area, it is enough to use sheets of formats: C18, C20, C21. Such structures do not experience heavy loads, so the strength of such a material is sufficient.

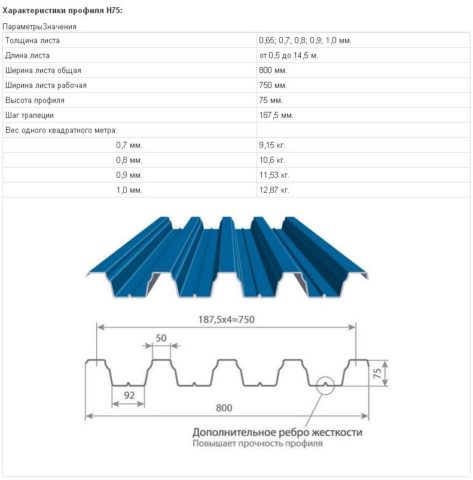

But there are also enhanced modifications of corrugated board (HC 35, H 60 and H75), the strength of which is excessive for wall cladding, moreover, their price is much higher than that of previous options. They are used in the construction of frame buildings, small architectural forms, roofing of a large area.

By the way! They provide additional reinforcing ribs-grooves to increase the strength of sheet metal. Therefore, even if you do not navigate the models, by this sign you can easily recognize such a corrugated board.

Conclusion

We hope that we were able to most fully answer the questions posed. We recommend that you additionally familiarize yourself with the attached video “Wall covering with corrugated board”.