Arrangement and decoration of concrete stairs

Finishing concrete stairs is a very important process, since not only the service life, and the appearance of the structure itself, but also the interior design of the house as a whole depends on it. Often, the staircase is the highlight, giving it an elegant and solid look.

This article will focus on what types of concrete stairs exist, and what is the technology for their production. Also, we will consider the question: "How to finish the concrete staircase in the house?"

The content of the article

Creating stairs inside the house

Stairs made of reinforced concrete are considered to be the most durable. Yes, these structures are also made of metal or wood, but in terms of their operational characteristics, they cannot be compared with concrete options for stairs.

- And it makes no sense to compare them. Naturally, in wooden house no one will carry out the construction of reinforced concrete.

And for brick and block houses - this is just what you need. - Concrete stairs can be divided into two categories. The first category is typical staircases used in industrial and civil engineering, and refers to prefabricated reinforced concrete.

Standard stairs are manufactured in the factory, in strict accordance with GOST.

- The second category is stairs, which are carried out directly on the construction site, according to an individual project. These stairs are monolithic.

They are more massive, and make them directly in the process of floor building walls. - The design of the stairs consists of one or two beams that play the role of a kosour, and steps - their number depends on the height of the floor. Concrete stairs are marching and spiral.

- Marching structures are the most convenient for the descent and ascent. They take into account the dynamics of human movement as much as possible.

Well, if the house under construction is so spacious that the marching structure is perfectly located in it, you can mount a precast staircase. The price of the stairs, in this case, will be cheaper.

- In conditions of limited space, a spiral staircase will fit into the interior best. This design, most often, is arranged for the descent-rise to the basement or the attic (see.Attic finishes: making the right choice).

- For the manufacture of concrete stairs, it is necessary to install the formwork, which must be rigid and durable. Otherwise, it may deform under the weight of concrete, and the design will turn out with defects.

- It may happen that it will have to be completely redone. Therefore, if you are building a house with your own hands, pay due attention to this moment.

Instructions and videos found on the Internet will also not hurt. - So, the formwork for pouring concrete is performed from a planed board, fitting every detail as tightly as possible to each other. If it was not possible to fit the boards well, then the inner cavity of the formwork must be beaten with smooth moisture-resistant plywood or hard sheets of fiberboard.

- This is necessary to ensure that the surface of the flight of stairs is smooth and as smooth as possible. And yet, this layer will prevent the absorption of wood moisture from concrete.

There are other options for achieving this goal. A smooth and well-fitted board can not be upholstered with plywood, but simply moisten well before pouring concrete.

Then the wood will expand, and, saturated with moisture, will not take it from the solution. - Formwork can also be made from a relatively new material, which not everyone knows about, OSB-4 boards. This is a type of chipboard, in the composition of which there are polymer resins.

Such plates have the necessary strength and moisture resistance, and are even used to stiffen supporting structures and partition walls. - Before pouring concrete, reinforcement is installed in the formwork. These are steel bars welded into the frame.

They must reinforce all the bearing faces of the stairs. The frame is a reliable protection of the structure from cracks and breaks.

Especially if there is no reliable support under the stairwells. - So that in the future, the front edges of the steps do not crumble, they are often framed with a corner. This is necessary if the steps will be finished, for example, with marble chips or tiled.

In order for the corner to adhere firmly to the concrete, steel wire antennae, which will be monolithic in concrete, are welded to its wrong side. - Next, you will need crushed stone with a fraction of 7-8mm. It is poured into the frame of the steps, and poured with cement mortar grade M400, which is carefully tamped and leveled.

To achieve maximum smoothness of the surface of the steps, no special boards are placed on them. - Three hours after pouring, they are removed, and the concrete surface is wetted with water. And to do this, in order to avoid the appearance of cracks, you need to regularly.

Despite the fact that the concrete has grabbed, it will be possible to walk the steps only after a full set of concrete strength. And this is 28 days. Then the formwork is dismantled.

And so we came to an equally crucial moment - decoration stairs. This is the next chapter of our article.

Concrete staircase finishes

Finishing stairs made of concrete, includes not only the lining of its steps and platforms. Finishing the back of the stairs, and the walls along the flight of stairs, is also of no small importance for creating a beautiful interior of the lobby.

As a rule, the staircase originates in this room.

Laminate in stairs

A concrete staircase is the best place for laying laminate flooring. The base under it must be rigid.

And what can be tougher than a concrete surface?

So:

- Finishing concrete stairs with a laminate is only decorative in nature, since this material is not particularly durable. And in this case, the strength of the staircase itself is such that it does not require additional reinforcement.

- If we are talking about a structure that is operated in an ordinary private house, then it is not subjected to such loads as a staircase in the entrance of a multi-storey building or office building.

- Since the width of the steps in some designs of stairs can be different, you need to measure the widest of them in order to determine the size of the laminated panels.

You need to buy material based on the number of steps. - And you need to keep in mind that for each of them, a solid laminate board is required. Castle joints on the tread surface would not be appropriate.

Facing risers should also not be performed from scraps.

There are different types of laminate, depending on the manufacturer. And they differ not only externally, but also in the way they are connected.

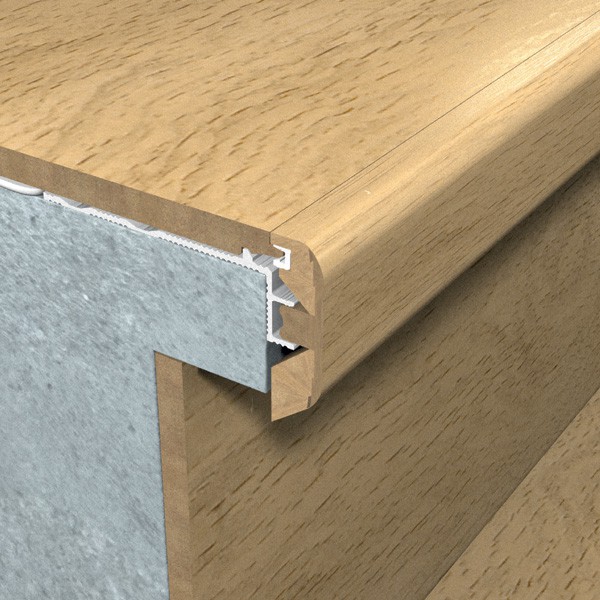

In the photo above, the steps are faced with a laminate, the elements of which are interconnected using a special profile. To lay the board on an even plane, the shape of the profile will be completely different.

Staircase design

Of course, if you use natural wood for stairs, you can get not only beautiful and durable steps, but also railings and balusters that harmonize with them. For this purpose, oak and beech, ash, larch, mahogany and ebony are used.

It all depends on the financial capabilities of the customer.

- And here the design options are practically unlimited. There are many companies specializing in the manufacture of various wooden products, including elements of stairs.

They can offer you an idea, develop a design, make custom-made elements for facing the stairs, and mount them if necessary.

- If the steps of the concrete staircase were finished with wood, then with it you can close the space under the stairs or simply trim them with the end of the march. The parapet, in this case, can be not only wooden, but also metal.

- You can talk endlessly about the beauty of stair railings. If it is a tree, then inlay, carving, gilding may be present in its design.

If the parapet is metallic, then there are even more options. - They are made of different metals: aluminum, stainless steel, copper or brass. The surface of these metals is itself beautiful.

But with forged steel fences, sometimes resembling metal lace, nothing can be compared.

- The use of one or another version of the fence, in many respects depends: both on the style in which the interior of the room is decorated, so on what material the steps are decorated with. In our example below, the concrete staircase in the house was finished with marble tiles.

- And how organically the glass parapet with stainless steel railings looks! Stone, concrete, glass and metal - these are the basic materials used in all modern styles: hi-tech, fusion, minimalism, techno.

- As for the back of the stairs, it is most often finished with decorative plaster. Especially if it is a spiral staircase, the curved forms of which do not make it possible to use any other material.

- In general, the back of the flight of stairs, which is clearly visible, can be finished with the same material as the steps. This is most convenient when ceramic or porcelain tiles were used in their cladding, as well as in the device for flooring.

This is not only a very durable coating, but also, with a creative approach - very original.

- Wall decoration along the flight of stairs also plays an important role in the interior. It often uses decorative plaster, and not only structural, but also Venetian.

There is enough space on this wall to embody any creative imagination of the master.

- Decorative stone is also a material ideally suited for this purpose. Moreover, a variety of stones can be used: dolomite, sandstone, rubble - and not only natural, but also artificial.

Such decoration is inherent in many styles in which the interiors of houses are decorated. This is a Gothic style, and a rustic, and a loft.

Each of the staircase finishing options mentioned in our article is good in its own way. The main thing is that both the design and the work on its decoration should be performed efficiently, in compliance with technology.

Then the staircase with its appearance will decorate the interior of the room, and will serve you for many years without requiring repair.