How to paint stainless steel: detailed instructions

Painting stainless steel is not entirely simple. We must first decide how to paint stainless steel and then apply a high-quality coating. After all, if you do not follow certain rules, then the coating will quickly peel off.

Today we will tell you how to paint a stainless steel without losing anything. Also on the video in this article and photo you can get additional information that will allow you to do everything efficiently and quickly.

The content of the article

The use of coatings

Painting stainless steel is a process where a carefully prepared surface plays a key role, rather than the stainless steel paint itself. So when doing the work yourself, you must adhere to certain rules, the instructions for this are described below.

Attention: In the event that the surface that was prepared was not thoroughly cleaned and there are defects, then such a paint will peel off quite quickly on a stainless steel.

So:

- Before staining the stainless steel, it must be subjected to a conventional grinder with a special nozzle. Sandpaper is selected with medium grain. The speed is set to maximum. Metal processing with the help of a machine is carried out by smooth movements with a slight pressure, which will achieve an excellent result and save a lot of time.

- Upon completion of treatment, the surface must be degreased with alkaline compounds or special acids. One of the most effective and cheap methods by which degreasing is possible is the use of a four percent solution of water and soda.

- For painting stainless steel, it is possible to use ordinary automotive paint with a hardener. Although the price bites her, but she is best suited for this. Do not forget that hardeners are added in large quantities, which will allow the paint to set and dry faster.

- Paint is applied to the surface using a spray gun (see We select a spray gun for painting). The use of a paint roller and brush is categorically unacceptable. If the stainless steel is painted with one coat of paint, this can lead to the fact that the coating can quickly lag behind the surface.

- Stainless steel paint is never applied in a single coat. There must be at least two. To enhance the effect, the paint is varnished, this will protect the surface from mechanical damage.

Mandatory conditions to be observed during the painting of metals susceptible to corrosion:

- Stainless steel paint is never applied in high humidity. Humidity should not exceed eighty percent.

- The operating temperature can be from + 50 ° C to 350 ° C.

- The surface to be painted must be absolutely dry and fat free.

Powder Coating Rules

In the event that you showed interest in advance and turned to specialists, then you probably were advised to powder paint. The secret of the method of coating with paint is that the application of paint is carried out using a spray gun (see How is powder painting performed?) Further, the coating is subjected to heat treatment in a special chamber at a temperature of two thousand degrees Celsius.

Subsequently, a film is obtained that provides surface protection from:

- Thermal impact;

- Mechanical damage;

- Exposure to an aggressive chemical environment;

- The effect of corrosion.

Attention: In addition to the listed advantages, powder coating has one more advantage, this is a unique decorative pattern. Powder paint lays on the surface with a uniform layer, but the addition of various additives allows you to diversify both texture and color solutions.

When using powder paint, you can get such effects as:

- Marble coating;

- Silver plated;

- Flat or bulk coverage;

- Glossy finish;

- Matte finish;

- Gold plating.

Attention: In the modern market, paint has appeared that simulates a stainless steel coating. Thus, the paint can be applied to a variety of surfaces.

As an example, give the painted stainless steel surface a wooden look, or the wooden surface a stainless steel look.

The advantages of this coating include:

- It is enough to apply one layer when using powder paint;

- Waste-free production using this type of paint. Unused paint can be collected and used again;

- The durability of the paint is due to its good adhesion.

- It is not necessary to expect drying of paint, the minimum time expenses during operation.

Painting technology

Stages of powder coating technology:

- Before staining stainless steel, it must be treated with degreasing and removing dirt.

- Apply a special composition that will create an inert phosphate film.

- Surface drying.

- Surface painting in a special chamber. The camera serves to capture the coloring powder.

- Heat treatment of the painted surface in a special furnace (see Do-it-yourself powder paint oven).

Attention: The only drawback is that without expensive equipment, painting the surface with your own hands is impossible.

Liquid paint

At home, stainless steel can be treated with liquid paints. The same paint is used that is used when painting ordinary steel. The difference is only in the methods of surface preparation.

Surface preparation

In order to achieve long-term use of the coating, preparation should be approached carefully.

Before staining, the following steps must be taken:

- The primary concern is surface treatment. To do this, use sandpaper. As an ideal option, use a grinding machine.

- An emery with an average grain size is put on a special nozzle. If the machine has a speed control mechanism, it is set to maximum. Metal processing with the help of a machine is carried out with smooth movements and with a little pressure, which will achieve a wonderful effect and save a lot of time.

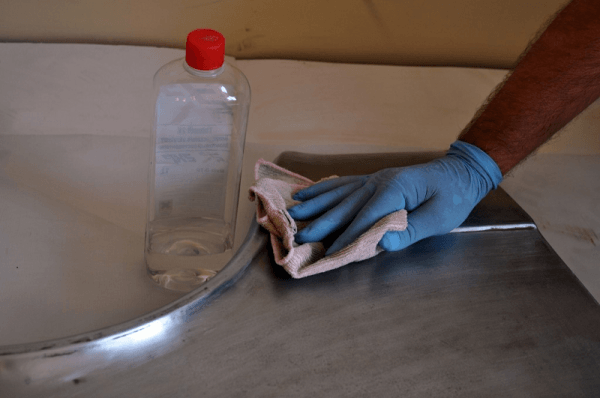

- Upon completion of pretreatment, it is recommended that the surface be degreased using specially selected alkaline compounds or acid.

- One of the most effective and cheap methods by which you can degrease the surface is the use of a four percent solution of water and soda.

Attention: The best solution would be to add a special hardener to the paint for cars to speed up its drying.

Paint application

Paint for stainless steel is applied using a special spray. The use of a paint roller and brush is categorically unacceptable. If the stainless steel is painted with one coat of paint, this can lead to the fact that the coating can quickly lag behind the surface. Therefore, there must be at least two layers.

Also pay attention:

- Humidity should not exceed eighty percent.

- The operating temperature can be from + 50C to 35C.

We do everything as follows:

- The coloring of stainless steel is done only with a fully mixed solution. After that, the atomizer tank is filled;

- Apply paint to the surface. When painting, observe the rules. The spray gun must be kept at an angle of ninety degrees from the surface, and at a distance of fifteen to twenty centimeters.

- The spray is moved relative to the surface in a straight line. During the movement of the “torch”, it should cover the area already prone to staining by fifty percent.

- At least two layers of paint are applied to the prepared stainless steel, if this is not done, then the paint will lag behind in the near future. After the first coat has dried, apply another one. In rare cases, a third layer is possible.

- To protect the surface from mechanical damage and give it improved properties, it can be coated with a layer of varnish.

Attention: Application of paints and varnishes is carried out only on a dry and fat-free surface.

How to paint a stainless steel you know and choose the right composition. The most important thing is to properly and accurately prepare the surface, because this will guarantee the durability of the coating.