How to polish varnish after painting wood

Painting a tree with varnish with your own hands is the final operation in the processing of wood, similar to the final touch when creating a picture. The glossy, smooth and radiant surface “sounds” quite especially.

The color becomes deeper, the picture is brighter, the product perfection, its beauty are emphasized, safety for a long time is ensured. What paints and varnishes can be used on wood, when decorating furniture.

The content of the article

Features of varnishes for wood

Wood is a material used for many purposes: from construction to the manufacture of furniture, souvenirs and tableware. However, for a long time not to lose their properties and attractiveness, structures and wood products can only if they are well protected from harmful factors.

In order to properly protect an interior item from their detrimental effect, you can turn to a trusted master who will help to maintain the attractive appearance of a wooden structure for a long time.

Wood is susceptible to:

- Dampness.

- Ultraviolet light.

- To the fire.

- Various pests.

Tip: Logs, boards, wooden parts for furniture assembly, floor laying should be pre-treated with varnishes. This will not only help maintain the attractiveness of the wood, but also emphasize its natural color or give the product a different shade.

After applying the varnish on wood to the surface, it should create a solid film that protects the wood for the entire life cycle. Before choosing wood paints and varnishes (seeWhat paint is better to paint a tree: we make a choice), it is necessary to determine the desired composition - they are all designed for specific tasks.

In this case, varnishes, depending on the proportion of oil and resin in them, can be:

- Oiledwhich are divided into:

- fatty;

- bold;

- skinny.

Such coatings have a relatively short shelf life, and after thickening become unusable. Oil varnishes are used to apply them to wooden floors.

Modern varnishes have a synthetic base and additives that protect wood from ultraviolet radiation. They are diluted with water or solvent before application.

- Phenolic and alkyd. To achieve saturation, these materials can be applied several times. Moreover, they:

- wear resistant;

- strong enough;

- not exposed to atmospheric conditions.

The varnish is selected depending on the purpose of the surface to be treated:

- internal work should only be carried out with safe compositions;

- outdoor - with good resistance to environmental influences.

- Acrylate. These are water-soluble, universal formulations. The presence of additives allows you to protect surfaces from discoloration from sunlight, such a coating can:

- apply to the log and beam during the construction of facades and fences;

- apply to cover ceilings and walls made of wood, doors (seeHow to paint the door: select the option) Their difference from other coatings is lower consumption per unit area.

- Urethane-Alkyd or Yacht. They are used for processing a wide variety of wooden surfaces, which can be:

- furniture;

- floors;

- handrail;

- all kinds of interior details.

Such a coating forms a quick-drying and high-strength layer on the surface.

In appearance, varnishes are:

- Glossy.

- Semi-glossy.

- Matte.

Instructions for choosing a varnish suggests taking into account its features.

Material must be different:

- Wear resistance. The varnish should be selected depending on the level of the expected load and the purpose of the surface. With a small load, it is enough to use ordinary varnish, and for flooring you need varnish with increased wear resistance.

- The smell. External work can be carried out with varnishes with any odors, including sharp and heavy, which have polyester, acrylic and polyurethane compositions. It is advisable to carry out internal work with odorless varnishes made on a water basis.

- Fire safety. If the surface will be exposed to high temperatures with a high risk of fire, a heat-resistant varnish is chosen.

- The number of components in the composition. Varnishes are available in one and two components. After applying a single-component varnish, a protective film is formed, obtained by evaporation of the solvent and drying of its residues. The formation of a film from a two-component composition is different:

- the solvent and hardener begin to enter into a chemical reaction;

- the protective layer is more reliable.

How to polish wood surfaces after applying varnish

Tip: To make the glass lacquered surface look like glass, polish the lacquer. Varnish does not give the expected effect. All smoothed by polishing the villi of the tree, from the varnish will rise and violate the appearance of the product.

There are several ways to make your own mirror-like shine on a wooden surface.

The most famous of them:

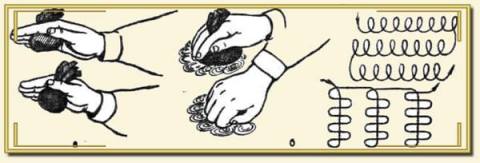

- Varnishing. In this process, all micropores are filled with varnish, which will not allow a new pile to appear. The resulting film will become resistant to water and dust, and the surface will receive a deeper and more juicy pattern. Processing is carried out with a cotton swab, previously wrapped in a clean canvas cloth that will not leave fibers on the treated surface.

- Wax coating. This is not a complicated process that you can perform on your own at home. After processing with wax mastic, the natural texture of wood will become more clearly manifested, the visual surface will become soft and velvety. This method is great for hard wood:

- ash;

- a nut;

- oak.

To improve the effect on soft woods: birch, alder, linden, wood need to be pre-tinted.

When applying wax, the distances between the wood fibers are carefully filled until the surface becomes smooth enough, after which the varnish is applied.

- Polishing. This technology allows you to create the most beautiful texture, preserving the pattern of the tree. The resulting surface resembles a mirror.

Tip: Do not polish wood with a large texture.

How to Wax a Tree

The technology for applying wax is as follows:

- Wood, previously cleaned by grinding from pile, is not covered with a large layer of mastic.

- After drying, the surface is wiped with a soft rag against the wood fibers.

Tip: After applying one coat, it is necessary to control the entire plane. Existing pores and cracks must be filled with wax. The surface should have a smooth appearance.

- The floor covering or product is kept warm for two hours.

- A second layer of mastic is applied with a soft rag, gradually increasing pressure on the surface, it should be smooth and matte.

- Paints, varnishes for wood based on shellac, applied in a thin layer, will give the polished surface the final look.

The disadvantage of this method is its low resistance to moisture, even a drop of water leaves its mark.

How to varnish a surface

Work is performed by shellac or oil varnish.

When applied by the first composition:

- The varnish is applied in two thick layers.In this case, all the bumps are well filled with the composition.

- All varnish is removed by grinding materials. The varnish remains only in cracks and pores.

- A second coat is applied. This is considered a preliminary primer.

- Dust is carefully removed.

- The third, thinnest layer of varnish is applied and left indoors for two days.

Tip: After applying this coat of varnish, do not allow dust to fall on it.

- One or two layers of topcoat are applied.

It is necessary to ensure that there are no smudges on the surface, which subsequently form spots. This can be avoided by applying a very thin layer of varnish without destroying the film formed after the previous operation. Everything is done quickly, evenly, efficiently, without stopping.

Tip: When applying oil varnish, please note that the composition dries for a long time.

For priming with oil varnish, a solution of:

- Varnish -200 grams.

- Water - one liter.

Liquid varnish is applied on a dried and carefully sanded surface with a thick brush. When the solution thickens, turpentine is added. The brush needs to be moved evenly, without applying sudden movements, the excess coating is removed. The formation of bubbles when moving the brush should not be allowed.

How to polish a surface

The process is as follows:

- The surface is primed in three layers of varnish. After applying the first coat, grinding is performed and dust is carefully removed. After that, two layers of varnish are applied on the dried surface.

- The swab is polished, a thin layer is applied. The product is dried and sanded with a grinder or abrasive materials. This process is long enough, it is better to use the technique for this. Several layers of polish are applied, each of them is dried and ground. As a result, the surface acquires a good gloss. To prevent sticking of the tampon during work, two drops of oil are added.

- The product is polished with a varnish, to which a small amount of oil is added, as in the photo.

The surface is rubbed with a swab until the desired gloss is obtained. To prevent the previous layers from dissolving, oil is added, at the rate of two drops per 10 cm². The process is repeated several times. Each coating layer is wiped with rags, which are pre-impregnated with a solution of varnish with water.

In order for the price of work to be minimal, and the quality of the applied coating to be good, it is necessary to observe the technology and the sequence of operations, and apply the required number of layers. How to apply paints, varnishes on wood, look after the product in the future shows the video in this article.