Primer for steel pipes: how to apply

The primer for steel pipes is of great importance for their protection against premature corrosion. This composition is intended for applying a lower coating layer to the metal before painting.

The primer allows for high-quality adhesion of the top coating to the base of the metal, strengthens its structure and stops various chemical reactions. Correctly selected type of primer for heating pipes will increase their service life.

The article will tell you how to choose the right primer and process steel pipes with your own hands.

The content of the article

Features of primer for heating pipes

Metal pipes are used for:

- Gutter devices.

- Communication gaskets.

- Mounting support structures.

Compared to other materials, metal has:

- More durable.

- Longevity.

However, a significant drawback is corrosion-free. Simple painting of metal pipes with oil paint does not give the desired effect: the coating will quickly begin to peel off, fall off, and corrosion will begin to form on the surface due to environmental aggression.

Tip: For long-term operation of the pipe, it is necessary not only to paint, but also to complete their processing with applying a primer.

Primer for steel pipes makes it possible:

- Ensure corrosion protection of the metal.

- Improve waterproofing.

- Convert rust.

- Apply as a standalone coating.

- Increase adhesion to the base coat and pipe.

- Compensate the difference in the coefficient of thermal expansion between the metal base and the paintwork.

- Reduce the absorption of paint, which reduces consumption on the final layer of enamel.

The correct choice of primer for metal depends on many factors.

The purpose of the product is taken into account:

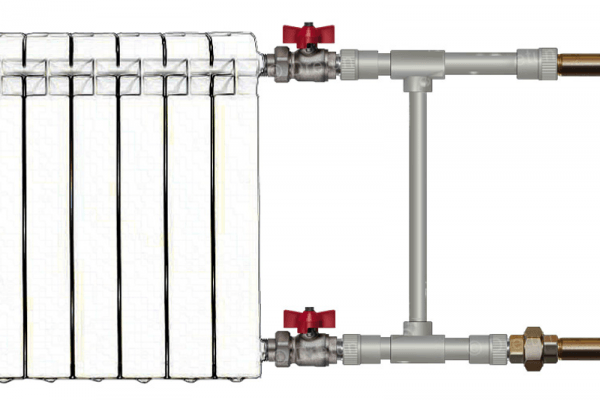

- If these are central heating radiators, all metal pipes are exposed to temperature changes.

- When supplying cold water, the pipes will be cold and wet.

- Hot water in the pipes creates a high temperature on the surface, which makes them too dry.

- The pipes may be gas.

- Placed on the street, which creates the vulnerability of elements from the effects of atmospheric phenomena.

- Settled indoors.

The quality and grade of steel affects the type of primer:

- Primers insulators. Such materials are made on the basis of ordinary paints - white, iron minium, with the addition of special additives to the composition, it can be an epoxy or alkyd mixture. After application to the metal, a strong thin film is created, which prevents the surface from contacting with the atmosphere. Used for outdoor pipes.

Alkyd primers are the most popular and have several advantages:

- applied as an independent coating;

- have high anticorrosive qualities;

- transform rust;

- provide protection against temperature differences;

- guarantee pipe durability.

Epoxy primers are designated as EP-0010, and GF-021 is alkyd.

- Two-component phosphating primers Is a mixture of active ingredients. When applied to a metal, it enhances its passivation, is used to treat any steel pipes, and has high adhesion. It is often used before applying any paintwork finish, enhancing its protective properties and reducing paint consumption. Primer marking - VL-02.

- Passivating Primers change the electrochemical characteristics of the metal, slow down the process of corrosion and the appearance of rust. Mostly used for wet pipes when laying communications. It is marked - GF-0119.

- Soil tread - This is a metal suspension dissolved in a paint base. Connections include:

- lead

- zinc;

- an alloy of zinc and magnesium.

On painted surfaces, tread primers create an imperceptible film that protects the metal base from scratches. Material marking - EP-0284, EP-057.

- Inhibitors are a new generation of protective enamel primers., are made on an oil and water basis, effectively and reliably protect pipes located on the street or in high humidity from corrosion. Oil soluble are labeled as EP - 180.

- Primer converter used for application by rust, phosphoric acid is used as the basis for the manufacture. The mixture converts iron oxide or rust to iron phosphate. After this chemical reaction, a protective insoluble film forms, which can partially restore the coating corroded by corrosion. Marking of compounds: XB-0278 or EP-0199.

Tip: Anticorrosion mixtures are used for pipes made of ferrous metal, and more adhesive - for pipes made of non-ferrous.

It provides a choice of primer and the temperature of the contents in the pipes:

- Up to 60 ° С. Such temperature conditions have central heating radiators and pipes for hot water supply. Subject to processing technology, it is possible to use primers made on a paint and varnish basis. The paint lays on the coating evenly, which reduces the consumption of material, it does not fade in the sun, does not exfoliate.

- Up to 100 ° С. Such compounds are used in private homes. Here, the owners can adjust the heating temperature themselves, the radiators are heated, while over 60 ° C. Soil is used ordinary, but the decorative coating should be chosen with pigments that are resistant to fading.

- Soil mixtures withstanding temperatures over 300 ° C. They are used only in industrial enterprises.

How to calculate the amount of primer

Tip: When purchasing a primer solution, you need to find out what its consumption per square meter of metal. Usually it is about 100 grams.

To correctly calculate the primer for pipes, take into account:

- The outer diameter of the pipe is d.

- Its length is h.

The coverage area S is calculated by the formula: S = π × d × h, where π ≈ 3.14.

Substituting the required values into the formula, the required coverage area is obtained. Multiplying it by the consumption for one square meter, the approximate consumption of the primer is determined.

How to primer pipes

The process of preparing and priming the pipes takes place step by step.

The work execution instruction has some features:

- Closes the walls and floor of the room.

- The surface of the pipes is thoroughly cleaned of old paint and rust. To do this, take metal brushes, brushes. The cleaning process is shown in the photo.

- Old paint is treated with a special solution to soften it.

- Scraped off with a spatula.

- Thoroughly to a smooth state and gloss, the surface is cleaned with an abrasive cloth.

- The pipe is washed and dried.

- Degreased with a suitable product.

- The primer is applied in the selected way, using:

- brushes, suitable for small diameters with irregularities. This takes more primer and processing time;

- small roller, effectively reducing the consumption of the mixture;

- spray gun or spray can under pressure. The price of paint in the spray can is much higher with a small volume, which is not profitable.

Tip: It is recommended that at least two coats be primed. At the first coating, small irregularities are carefully filled.

The primer for pipes must be carried out before the final coating, which allows the latter to be well fixed. Processing is carried out at room temperature with the heating turned off. This ensures proper drying, improves surface quality and reduces primer consumption. The processing process itself is offered on video.

Correctly executed coating on steel pipes is a guarantee of their long-term use.

Once upon a time I read in one Soviet publication that a layer of paint on batteries can significantly reduce heat transfer between the battery and the room, even a figure of 60% loss was flashed. An ideal solution would be to chrome the batteries and the appearance is excellent and the heat will be lossless. And the connecting pipes can, in principle, be primed and painted. This is probably true for those who are cold in the winter and who have a centimeter layer of paint on batteries.

Usually, an epoxy primer is not used, but is applied to metal pipes and heating radiators GF-021, and then PF-115 enamel is painted on top. The primer consumption is indicated on the can, and the exact surface area of the pipes can be found in the tables.