Wall paneling: decoration of facades and interiors

Wall cladding with hinged panels is perhaps the most rational option for decoration. And this applies not only to the external walls of residential buildings - the panels also fit well into the design of the premises.

As for offices and administrative buildings, then wall paneling is the most practical, and such interiors look quite solid. In this article we will talk about what types of panels are used today for wall decoration, introduce you to the technological nuances of their installation, offer a video on this topic.

The content of the article

Facade panels

Currently, the range of finishing materials is so wide that there is something to be confused about, not knowing what to choose. Everyone wants a “three in one”: and aesthetics of the facade; and quick installation without wet processes; and, of course, not too exorbitant price of the material.

So:

- Wall panels for facing fully meet all these requirements, and you can always find an option that will satisfy the most demanding customer. Their undoubted advantage is the fact that you can independently carry out works on the arrangement of the facade.

- Special knowledge and professional skills are not required here - the manufacturer’s instructions usually provide comprehensive installation information. This is not at all such a complexity of work as, for example, decorative plastering of walls.

About the nuances of the production of facade works using hinged materials, we will introduce you a little later. In the meantime, we’ll talk about what types of panels for wall cladding can be found today in the construction markets of the country.

Modular panels

| Appearance and name of the panel | Cognitive Material Information |

| Exterior finish the walls of the building, it requires certain operational qualities from the material used - because the facade must be protected from the cold, and from moisture, and from wind loads. Panels in the manufacture of which various polymers are used fully meet these requirements.

In appearance, it is most often imitations of various breeds of natural stone: buta, quartzite, dolomite, tuff. Modern technologies make it possible to achieve any relief and shade, so manufacturers offer such a huge assortment that it is sometimes difficult to make a choice.

Panels for facing plinth may have a size of 1140 * 480 mm. Wall options are also more overall, for example: 3800 * 380 mm. The thickness of the panels is usually not less than 16 mm. As an example, we have brought to your attention both options.

By the way, lining the inner walls with plastic panels is also possible.This does not mean, of course, that they can be used in the decoration of living rooms, but the veranda, lobby, balcony or loggia with such a lining will look just fine.

|

A fiber cement panel is a modular material of a given configuration and size, with a specific fastener design provided by the manufacturer. They are molded from cement mortar, with mineral fillers, the addition of cellulose and modifying additives.

It can be polymer coatings, and paintwork, and even photoceramics. And if plastic, even though it is resistant to high temperatures, but still burns, then fiber cement panels are absolutely fireproof.

Therefore, fiber cement panels are equally good as for facade decoration, and for the decoration of the premises - and not only for the corridor or balcony. One inner wall, lined with such panels in the living room or bedroom, focuses attention on yourself, highlighting a certain area. In addition, it will be possible to simultaneously insulate and soundproof the room.

| |

Thermopanels occupy a special niche among finishing facade materials. Their fundamental difference from other panels is that the front surface is a natural material, not imitation.

As a result, light and beautiful panels are obtained, with the help of which the facade can not only be lined, but also insulated. Facing a wall with a wall panel, in this case, can be done in two ways: on the frame, and on the glue. But, the second option requires preliminary alignment of the surface.

| |

| Everyone knows that ceramics are made from clay, and have been used by mankind for centuries. But hinged ceramic panels that can be mounted not on a mortar, but on a crate, were invented not so long ago. They are one of the most solid, and, frankly, not cheap materials used today for the assembly of ventilated facades.

The high cost of such panels does not particularly scare the consumer, since the respectability of the exterior of the building, and the durability of its finish are worth it. They are used even for facing high-rise buildings. Under the table we gave an example of such a finish - judge for yourself how harmonious such a facade is.

|

Here is the facade of a high-rise building, lined with ceramic panels:

Modular panels are distinguished by the fact that each of them is an independent cladding element, which does not require refinement: shaping, cutting, milling it. As a rule, additional elements are attached to them, allowing to give the wall a finished look.

Sheet and long panels

| Appearance and name of the panel | Cognitive Material Information |

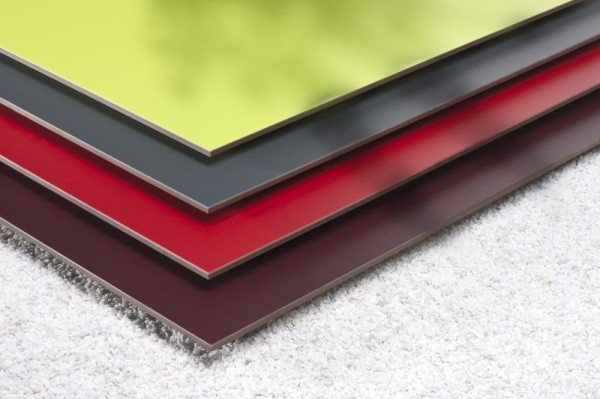

HPL panels are another option for façade finishes that use polymers. Only the technology of their production is completely different. And the panel itself is not a separate module with a locking or tongue-and-groove connection, but is a sheet material. The sheet size is 4100 * 1850 mm, although it may vary slightly.

HPL panels are non-delaminating, light in weight and flexible enough to cover a spherical surface. Therefore, they are suitable for facing columns, or semicircular facade elements. They fundamentally differ from other types of panels: their surface does not imitate the reliefs of stone or brick, it can only be a wood drawing.

By correctly combining different shades, you can create a design that no other material can handle. What can I say - look at the photo at the beginning of the article, and you will understand everything. | |

| In appearance, the aluminum panels are similar to the HPL laminated plastic, which we talked about above. But the similarity ends here - in structure these materials are completely different. ACP facade panels are a multilayer composite, which is a “sandwich” of two layers of aluminum, and a polymer insulation enclosed between them.

This is the most expensive version of composite aluminum, since the Teflon coating gives their surface additional hardness, fire resistance, and resistance to any aggressive environment. Such panels can be faced not only the facade, but also the production workshop, where corrosive vapors and elevated temperatures affect the structure.

|

For centuries, wood has been used by mankind for the construction and decoration of houses. This material has only one drawback - it is afraid of moisture. To finish the facade, such material is expensive: all elements of the crate require antiseptic impregnation, the surface needs to be finished, and the wood itself, if it is of good quality, is not cheap.

Composite wood is obtained more durable and durable, and most importantly - it does not need protective impregnation or finishing. |

This is not a complete list of materials used for frame facade cladding. There are many other options: professional sheet; sandwich panels; long siding; front thermal wood; slabs of porcelain stoneware and natural stone that can be mounted on a frame. But, it is impossible to tell about everything all at once within the limits of one article.

The main stages of cladding

We will pay a little attention to the technology of the work, and briefly describe how to wall the facade with wall panels.

If the walls of an old building are sheathed, then you need to start with their preparation:

- This is the dismantling of the old cladding, or the removal of plaster, sealing cracks and holes, removing dust. If the walls are made of bricks, and they are very curved, you have to align them a little: cut down the mounds, plaster the recesses.

- Then, waterproofing: impregnating or rolled - it depends on the material of the walls. Impregnation is better for concrete and brick, and a rolled membrane for wood.

- A very important step in the work is markup. This is the line along the lower perimeter along which the starting profile is mounted, the installation lines of the vertical crate belts, and the location points of the mounting brackets.

Expendable materials

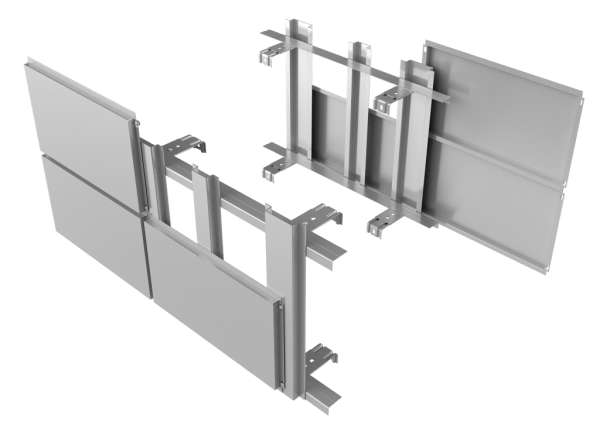

The set of parts and materials necessary for equipping a ventilated facade varies depending on the type of panels, their configuration, as well as the design of the fixtures. In addition, the ventilation façade can be insulated, which, of course, reduces the consumption of material during wall cladding.

So:

- To install the frame in most cases, three types of profiles are used, having sections in the form of letters "L", "T", "Z". The corner is mounted along the starting line, and serves as a support for the lower row of insulation, if it is laid in the structure. The other two profiles are vertical struts and transverse belts.

- Profiles are mounted on brackets, the main task of which is to provide the necessary indentation of the decorative surface from the base base. With their help, the spatial position of the cladding is also leveled. To fix the brackets to the wall, use a dowel-nails.

- Some panels are attached to the frame with the help of clamps - for example: ceramic granite. Metal cassettes, as well as some types of fiber cement panels are fixed with screws, which can be closed with a decorative profile, or by themselves can be a decor for cladding.

The manufacturer offers all these elements in the kit, because it is not always possible to assemble a frame from disparate parts. But the windproof membrane, insulation, and fasteners for it, can be purchased independently.

Otherwise, you need to strictly follow the recommendations of the panel manufacturer, and you will get a beautiful and warm facade, lined with your own hands.