Drywall plastering begins with the choice of material

Drywall puttying is always done at the end of all work. The appearance of the final coating directly depends on this.

Also, the service life, that is, durability, will depend on the quality of this work. Therefore, this is a pretty responsible job.

First of all, you need to choose the right material for the job. After all, it is different and therefore it is necessary to start with this.

The video in this article will show the whole process of work visually, then it will be much easier to do everything correctly.

The content of the article

We choose the material for the production of putty

First, the material from which the putty is made is selected. It has various properties and here special attention should be paid to the surface environment. Everything can be done with your own hands and therefore the price of decoration will not be high.

Attention: If you have high humidity in the room, then the putty should be resistant to high humidity. Otherwise, she will not last long.

| Gypsum putty | Plaster based putty is not only distinguished by its whiteness, but also by its ductility.

|

| Cement putty | Cement-based putty is usually used not only for internal but also for external work.

|

| Polymer putty | In the room during finishing works, polymer putty is widely used. In addition, this putty is used to seal joints, joints of various cracks resulting from the penetration of water. |

| Universal putty | Universal putty is distinguished by high strength, which after application forms an even surface of white or gray color with no visible defects. |

Intended classification

Front putties all types belong to the so-called finely dispersed materials, but depending on the purpose of the putty, they may contain fractions of various sizes.

Also, ready-made solutions for various tasks may differ in consistency.

On this basis, mixtures intended for facade work are divided into several groups:

- Starting (leveling or basic) putty.

- Finishing putty (mixture with finer than starting grain). In this case, the finished solution usually has a more liquid consistency.

Attention: Finishing putties are used to finish the alignment of walls and give a perfectly even and smooth surface, which is very important for further decorative finishing. Do not try to impose it in a large layer, for this it is better to use the starting option.

The mixture is usually applied with a sufficiently thin layer, the thickness of which does not exceed 4 mm.In terms of strength, this putty is inferior to the starting one, but at the same time it is more pliable and is well polished.

- Universal putty. This material combines the advantages of the two types described above, but is not used for putty in places with high humidity. And strong temperature extremes are best avoided.

- Putty decorative. Using this type of putty, stucco moldings or textured decorative elements are performed on the outside of the drywall. But it should be remembered that it is suitable as a decorative coating. But she is afraid of moisture and mechanical stress and this should be taken into account.

- Hard putty on wood. For drywall, it is suitable. It is usually used not only to impart smoothness, but also to protect wooden or wood-clad walls from various climatic influences.

Types and characteristics of putty

Start

It is used for internal repairs:

- This building mixture has a coarse-grained structure, as well as excellent adhesion and excellent sanding, which paves the way for the final stage of repair.

- Start can also be applied when roughing lime, concrete, brick foundations, as it perfectly closes cracks and excavations of the most diverse depths. In this case, the thickness of the layer to be applied varies from 2 to 20 mm.

Finishing putty

This type of putty is suitable for outdoor applications and at the same time has a fairly finely divided fine structure. She can On sale she can be found in dry and cooked form.

Its unconditional advantages are:

- Frost resistance;

- Elasticity;

- Vapor permeability;

- Water resistance;

- Good environmental performance.

Caution: Before buying a mixture, the instructions should be studied. All listed qualities in each separate material can be different. Therefore, again, before the plasterboard putty, an important indicator is the surface environment.

- Apply the finish for puttying before the final finish. This material can be used in areas where there is a high degree of absorption and low strength, as it strengthens the surface.

- All putties intended for outdoor use must necessarily be on a polymer or cement basis, since the substances in their composition very stubbornly withstand all kinds of weather conditions and give the necessary surface strength.

- Before buying, the instructions should be studied, because the manufacturer can release the material with some features and they need to be known in advance.

Application features

When filling gypsum plasterboard, it is important to observe some rules of work:

- Before starting work, you need to carefully prepare the base where the finishing putty will be applied. The entire surface should be cleaned of dust, dirt, oil stains, various influxes of rough finish. The surface should be free of significant cracks and depressions.

- If poorly fitting paint coatings remain, then they will need to be disposed of. Naturally, ideally, finishing puttying is done on the starting layer.

- Before applying the putty, it is necessary to treat any surface with a primer with the properties of deep penetration and allow time for it to dry in accordance with the manufacturer's instructions.

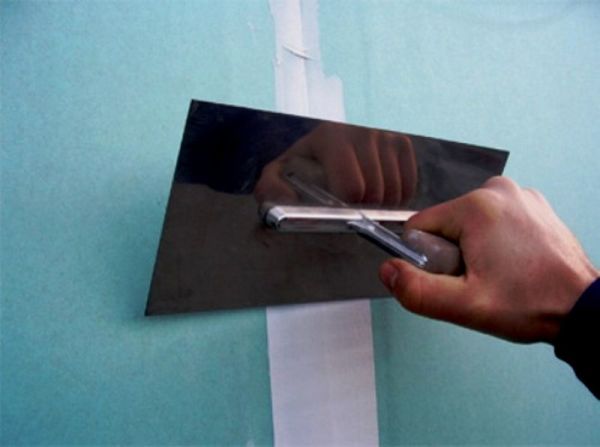

- It is preferable to work with finishing putty using a building grater or a pair of metal spatulas. It is unlikely to immediately be able to get an absolutely smooth surface.

For this reason, it is usually necessary to impose several layers, while the thickness of each of the layers cannot exceed the parameters indicated on the manufacturer’s packaging.

- After drying, putty for outdoor use is sanded quite easily.

Hard putty application conditions vary from humidity not exceeding 80% and temperature not lower than + 5 ° C.

Attention: It is worth noting that the putty hardens faster at elevated air temperatures. But it is most convenient to work with it at a temperature of + 20 ° C.

- It is not allowed to mix any putty intended for finishing with other building materials, such as loose mixes.

- It is also better not to apply it to areas and surfaces that are very hot and are exposed to the sun at the time of application. At the same time, crude putty does not tolerate water splashes and low temperatures.

- The most common area for applying the finish is the slopes of doors, windows, walls, as well as the treatment of surfaces that are insulated.

- Putty drywall in preparation for finishing finishing work.

- The surface after grouting, priming is painted or applied with facing material.

- Sanding the material lends itself quite easily and does not crumble.

- At the final stage of finishing, in order to eliminate smaller scratches and cracks, a finishing putty is used. It is applied to the surface with a millimeter layer.

- Typically, such a material is applied not in one but in several layers, and each applied layer must be well dried.

- The layer thickness should not exceed the norm, otherwise the surface may become cracked.

Putty is a fairly inexpensive and quick way to clean up the drywall plane. In addition, the walls will not look faceless. The rules for plasterboard puttying are now familiar and you have a huge scope for creativity, because you can combine any shades and colors, add any decor elements, as a result of which your house will stand out from the rest of the houses.