Drywall putty independently and efficiently

Drywall putty is freely available at retail. And everyone can do the work with their own hands.

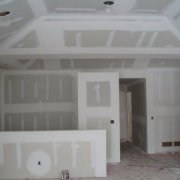

Today we decided to tell how plasterboard putty is made. In the video in this article, you can see everything yourself, and the individual stages of the work will be presented in the photo.

The content of the article

Doing work yourself

Drywall Putty do-it-yourself process is not complicated, but rather painstaking. The whole question is in the mixture itself, which quickly hardens.

And if you do not have the skills to do the work, then do not knead a lot of it. The price of the material is not expensive, but after each hardening of the material, the container has to be washed, and this is the time.

The following is an instruction on how to do the work.

Preparatory work

The visual appeal of drywall constructions is largely determined by the quality of surface preparation for putty. Even the smallest, at first glance, flaws can not only significantly complicate the process of processing walls, but also significantly delay the repair time.

So:

- First of all, you need to check the quality of twisting of screws. To do this, it is enough to draw a trowel along the vertical row of twisted screws. If the tool moves smoothly, without jerking, hooks and characteristic metal sounds, then everything is fine. Otherwise, the screws should be tightened.

- Screws screwed with excessive zeal can deliver no less trouble. You can define them only visually.

Self-tapping screws "recessed" by more than half the thickness of the sheet must be twisted, and the holes from them are sealed with putty. The new mounting location should be at least 4 centimeters away from the putty.

The choice of putty

The range of mixes in construction stores is very wide. Depending on preferences, specifications and budget, you can choose both ready-made putties and dry mixes.

The latter must be diluted with water before use, in strict accordance with the instructions.

Attention: When choosing a putty, first of all, you need to focus on the level of humidity and room temperature. Without taking these factors into account, it is impossible to correctly select the composition of the mixture, and therefore, ensure the durability of the repair.

So:

- An important characteristic is the strength of the composition. This is due to the fact that the rigidity of the entire structure depends entirely on the quality of the seams. The better the joints between the sheets of drywall are repaired, the more the wall is resistant to external influences.

- In the event that the mixture is selected for residential premises, environmental friendliness becomes one of the priorities. Despite the fact that most putties are absolutely safe for human health, before buying it will not be superfluous to ask the seller for a certificate of conformity.

You can consult with him in case of any doubt about the correctness of the choice.

Putty Technology

Attention: Before starting work, it is recommended to make sure that the room temperature corresponds to the range recommended by the manufacturer and there are no drafts.

Putty technology involves the following work sequence:

- The first step is to remove dust and small particles of material from the drywall surface, which inevitably appear when twisting screws.To do this, use only a dry rag or brush.

- A special primer should be applied to tighten the screws and the joints between the sheets. This will provide additional protection against moisture and improve adhesion to putty;

- At the next stage, all seams must be reinforced with a special tape. Despite the fact that it is considered to be self-adhesive, it is better to fix it with putty. She also needs to close up the places of screwing in the screws;

- After the putty dries, the seams again primed, and a bandage of paper tape is applied to them. The banding technology is quite simple.

A thin layer of glue is applied to the seam, and the tape is moistened. One of its edges is attached to the very top of the seam. After that, the bandage is gradually glued to the joint with a spatula.

This should be done as carefully as possible, trying to smooth the surface as best as possible so that even the smallest air bubbles are not left under it; - Fully dried bandage tape, sealed with finishing putty.

- After all the seams are closed, you can go to the first layer of puttying the walls. There will be 2 or 3 of them, as a rule, it depends on the skill of the master and the correctness of the processing of seams. However, you should definitely know that you can go to the next layer only after the previous one has completely dried.

- To take the solution from the container in which it is prepared, and apply it to the wall more conveniently with a small spatula. But the leveling must be wide.

It is believed that the wider the tool, the smoother the surface. However, abuse is also not worth it. A large spatula, without the appropriate skills, is very inconvenient to work with; - On a damp surface, it is almost impossible to see the bumps. Therefore, experienced craftsmen always use lateral lighting when working. As a rule, this is a portable lamp mounted on the left or right side, at a small distance from the wall. Falling at an acute angle, the light gives out all the flaws;

- As soon as the surface becomes sufficiently smooth, it must be thoroughly dried. After that, problem areas need to be treated with a special painting grater (seeHow to grind walls after putty and how to do it right) With its help, the wall can be given the final smoothness.

- The final stage of finishing work is painting GKL or wallpapering the walls.

Putty Consumption

It is very difficult to say in advance how much putty will be used to process this or that design. Putty consumption per 1 m2 of drywall depends on the surface roughness and other factors.

All this is individual and depends both on skills and on the desired result. However, if we talk about average values, then they lie in the range of 250-300 grams per 1 m2. It is these data that need to be guided in the preliminary calculation of the material.

Putty of external corners

In practice, the corner is the most vulnerable spot on the wall. Therefore, before proceeding with puttying, it must be protected. For this, in any store, you can buy perforated metal corner.

It is installed in the following sequence:

- Trim the metal workpiece to size using scissors for metal;

- To putty on a surface of the processed external corner. At the same time, it is necessary to ensure that its layer is thick enough and does not have gaps;

- Press the metal corner all the way to the putty. It is very important that there is no air left under it;

- With the help of the building level, an ideal vertical or horizontal is set, depending on the location of the external corner;

- Putty, which is squeezed out through the holes, needs to be carefully leveled, and excesses must be removed.Do not try to achieve a perfectly flat surface, at this stage it is almost impossible.

- The final alignment of the angle occurs simultaneously with the filling of the entire surface of the wall. It is the angles, due to the presence of perforated structures, that are the most “protruding” point and most often determine the number of layers.

Putty of internal corners

In processing the angle, it is necessary to make not only a qualitative plane, but also to maintain its correct geometry. After all, inaccuracies will immediately catch your eye.

So:

- To reinforce the internal corners, a serpentine tape is used.

- It is fixed so that the middle of the width of the tape coincides with the joint.

- Puttying the inner corners will be much more effective if armed with a special trowel. It will make the angle perfectly flat and smooth.

- In the event that it was not possible to find it, you will have to do with an ordinary spatula. With its help, one side of the corner is leveled first, and then the other.

As you can see, everything is not so complicated. And it doesn’t depend, putty putty or any other is used. The work is carried out precisely according to the listed rules and the main thing in this matter is not to rush and do everything carefully.