Putty for concrete floor: purpose, types, application

Floor coverings experience a very high load. In addition to the fact that they must be durable, they are subject to increased requirements for wear resistance, resistance to moisture and aggressive environments.

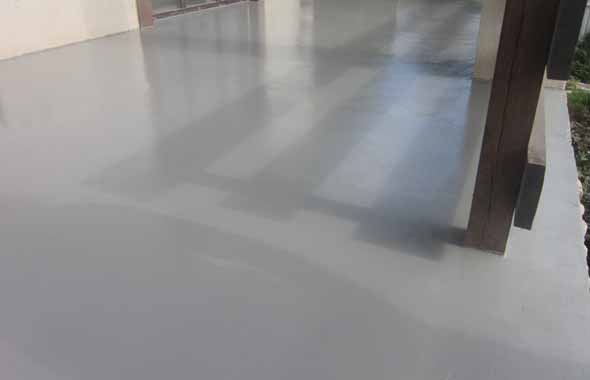

Equal surface and aesthetic appearance are no less important. All this can provide putty concrete floor.

The content of the article

Application area

Concrete floors are most often found in industrial buildings: in factory floors, warehouses and retail premises, garages, etc. Here they are subjected to serious mechanical stresses, chemical and physical influences, and therefore must have a number of special properties.

In residential premises, such floors are the basis for decorative coating:

- Linoleum;

- Laminate flooring;

- Parquet and floorboard;

- Ceramic tiles (see Ceramic flooring - the right veneer);

- Paints;

- Bulk polyurethane floors;

- Porcelain tile (see Porcelain stoneware: practical and stylish).

These materials are laid only on a flat and smooth surface, resistant to moisture and mechanical damage. It should not crack and crumble, emitting harmful dust into the air.

Putty for a concrete floor or cement screed allows to improve the quality of the base, but for this it itself must have certain properties, which include:

- Water resistant;

- Moisture resistance;

- Mechanical strength;

- Resistance to wear;

- Durability;

- Environmental friendliness, safety of use.

In addition, the putty should adhere well to the base, have high adhesive properties. What materials meet these requirements?

Types of putties

Like any other, putty for concrete substrates is a mixture of binders with water. Also, its composition may include fillers (sand, crushed stone) and additives that increase plasticity. Bonding agents include glue, cement, polyurethane, polyester, epoxies, etc.

The industry produces many types of such putty. These can be ready-to-use pasty masses or one-, two-, three-component dry mixes, closed with water before use.

The price of finished materials is quite high, so putty for the floor is often made with your own hands from available materials - cement, sand, PVA glue, drying oil, acrylic varnish, etc.

Before we talk about the most popular types of putty, we note that regardless of the composition, it is divided into basic and finish:

- Base mixes are designed to correct bumps, repair cracks and potholes on the concrete floor. They contain more filler;

- Finishing compounds are more plastic and designed to make the surface even and smooth.

For reference. There are also universal putties that can be used for any of these purposes.

Cement mortar

They are most often prepared with their own hands and used to level the base for sheet or typeset flooring.

The process looks something like this:

- First, all surface defects are cleaned and primed with PVA glue diluted with water. Proportions: 1 part glue to 5 parts water.

- Then, to seal these defects (shells, crevices, cracks), a mixture of cement, sifted chalk and slightly diluted PVA is prepared.Also, basic putty can be prepared from cement putty and acrylic varnish, using fine wood filings or sand as a filler.

Tip. If the defects on the surface are minor, they are puttied with ordinary oil or adhesive putty.

- After the patches have dried, the entire surface is cleaned of dirt, debris and dust and primed with a solution of acrylic varnish or the same PVA glue.

- For leveling, putty is prepared from cement and pure fine sand, diluted with the same solution of PVA glue (1: 5 with water). It should turn out to be liquid enough so that it can be poured onto the surface and leveled with a spatula.

Note. The layer of finishing putty should be no thicker than 3-4 mm. If a large thickness is required for leveling, then it is poured in two or three steps with drying of each layer. Drying time is about 2 hours.

To level a large area, putty is prepared in portions that can be laid in 10-20 minutes, since after this time the solution begins to set and loses its properties.

Polymer putties

Special recognition of consumers deserved self-leveling mixtures that appeared not so long ago in the construction market. These are liquid polymer-based formulations, which include additives that increase the strength and hardness of the coating. The film formed by them does not deform, does not shrink, does not crack.

The most popular and high-quality are compositions with a polyurethane or polyester binder base. They are supplied as mixtures of two to three components.

The amount of each component in the manufacture of putty is determined by the instruction depending on the purpose of use: more filler is introduced into the base, less - into the finish.

The fluidity of the finished solution is determined by the presence and size of surface defects. In the presence of shells, small cracks and potholes, it is prepared based on 1 part of the dry mixture - 5 parts of water.

The liquid solution penetrates the pores and cracks better, filling them and creating a monolithic base. A relatively flat surface is puttyed with a solution prepared in a 1: 3 ratio.

Note. Polyurethane putties also have a limited time of use, which, depending on the composition, can be up to several hours.

Concrete floor puttying technology

The surface of the floor before repair is cleaned of dirt and dust. It is most convenient to do this with an industrial vacuum cleaner. Then it is primed (see Primer for floors - features of application) to provide a more tight grip with putty.

The solution is poured onto the surface and leveled with a brush or a comb spatula, trying to create a uniform thin layer (2-3 kg of mixture is consumed per 1 sq. M). Since it is quite liquid and fits on a horizontal surface, the work is done without much effort.

The drying time of the base solution before applying the finish is at least 24 hours at an average temperature and humidity. The same amount of time is required for building strength with fine putty. After which the surface is ground with abrasive materials.

Conclusion

Puttying concrete floors is much easier than walls or ceilings - in this case, the force of gravity helps, but does not impede work. Therefore, everyone can cope with it.

And if you carefully watch the video in this article, then there will be no questions and doubts at all.

Tags: concrete