Stone cladding - a practical and durable solution

The facade of the house is an indicator of the taste, welfare and social status of its owner. The stone cladding of the building gives it a solid, elegant and respectable appearance, allowing for many years to forget about the need for its external repair and maintenance in its original form.

This noble material does not require care, pleases the eye and reliably protects the structure from any external influences.

The content of the article

Types of facing stone

For exterior decoration of facades both natural and artificial stone are used. Both the one and the other are distinguished by such characteristics as service life, resistance to temperature extremes and other weather phenomena, wear resistance, environmental friendliness, high noise insulation and protective properties.

A natural stone

Natural stone in the cladding of buildings is used not only in the form of plates. Various decorative elements are also made from it: columns, balustrades, pilasters, staircases and railings, etc.

The most popular and popular breeds:

- Granite;

- Marble;

- Limestone;

- Travertine;

- Quartzite;

- Slate; dolomite;

- Shell rock, etc.

All types of stone have different cost and processing complexity. The most expensive are granite and marble, the minimum price is for limestone, shell rock.

Attention! Often, to reduce the cost of lining, a combined finish is used: plaster + stone or different types of stone. It should be remembered that the contact of carbonate (shell rock, limestone, marble) and silicate (sandstone) rocks should not be allowed, upon the contact of which destructive chemical reactions occur.

Despite all the advantages of natural material, it also has significant shortcomings, which often become the reason for refusing this type of finish. In addition to the high cost, this is a big weight and the complexity of installation.

So:

- Stone cladding of buildings requires careful preparation: building a foundation that can withstand heavy loads and strengthening load-bearing walls. And these are additional expenses and labor costs.

- During the decoration, it is necessary to trim the individual cladding elements in size. Only true professionals can do this accurately and efficiently.

In a word, building cladding natural stone is a very expensive pleasure. Moreover, not only the material itself costs a lot of money, but also the preparatory work, and the installation itself.

Note. In the event of damage to one or more stone tiles from the cladding, it will be very difficult to find a replacement for them in exactly the same color. Therefore, purchase material with a small margin.

Fake diamond

This material is made from a mixture of high-grade cement with sand, crushed natural stone, various additives that improve its strength characteristics and moisture resistance, and fillers that reduce the mass of products.

Attention! Some types of artificial stone are made on the basis of gypsum. Such a stone for facing the facade of buildings is not suitable - it is used for interior decoration.

The main advantage of this material: having a practically indistinguishable form from a natural one, it has 2-4 times less weight.

This is achieved just by introducing into the raw material mass such fillers as:

- Expanded clay;

- Ceramic chips;

- Expanded perlite

- Natural pumice stone, etc.

Due to the light weight of the products, the cladding of buildings artificial stone does not require such careful preparation of the foundation and surface, and ease of processing reduces the qualification requirements for performers. Moreover, having some experience in laying ordinary ceramic tiles, you can finish the facades with your own hands.

The work is facilitated by the fact that the back of the tiles of artificial stone is always flat, and its shape is correct, sustained in the given sizes, which eliminates the need to fit the elements to each other.

The production of this decorative finishing material is carried out by means of vibration casting: the mixture is poured into molds and subjected to vibration, as a result of which it is compacted, and the most durable and heavy particles settle to the bottom. As a result, the tile gains increased strength precisely on the external decorative surface, which will account for the maximum operational load.

To get the desired color, the products are painted, and this happens in one of the following ways:

- Only the front surface is exposed to staining during the manufacturing process. Chips on such a stone will be clearly visible.

- The dye is introduced into the raw material mixture and mixed with it. An artificial stone made in this way for cladding buildings more likely imitates natural, it is not afraid of minor damage, rains and sun rays, it will not lose its original appearance even after many years.

As for the form and texture, they are very diverse and can imitate both rocks existing in nature and completely fantastic, which have no analogues in the world around them.

In general, an artificial stone by type can be divided into three large groups:

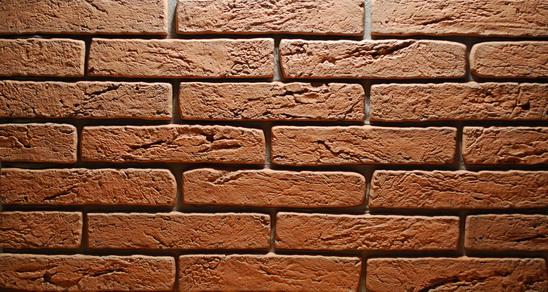

- Under a brick - imitates different types of ceramic bricks, including aged and old;

- Sawn stone - tiles of standard rectangular shape and the same size, the front face of which imitates the cleavage of natural stone;

- Chipped stone is an imitation of pebbles, cobblestones, boulders and other naturally formed stones.

That is, wanting to clad your house with marble, granite, onyx, sandstone or other types of stone, but not having enough funds for this, you can easily replace them with a cheaper artificial analogue without loss of appearance and practicality.

In addition to a significant reduction in the load on the supporting structures and a significantly lower cost, this material has other advantages.

So:

- High strength possessed by facing stone - the building will be reliably protected from any external influences;

- Moisture resistance is higher than that of natural stone due to the absence of pores. Accordingly, it has better frost resistance;

- Reduced thermal conductivity - due to the introduction of special additives;

- Environmental safety - all components are completely harmless.

Mounting Methods

Facing buildings with stone, regardless of its origin, can be done in two ways - dry and wet.

The first is the fastening of individual elements (tiles or panels) mechanically to a pre-mounted frame. It allows you to radically change the appearance of wooden and frame buildings.

At the same time, they can be insulated by fixing heat-insulating plates on the walls, which are completely hidden by decorative cladding.

For this type of decoration, stone slabs of large size and the correct standard shape or panels of artificial stone in the form of several tiles are used.

For reference. Such facades are called ventilated curtain systems.Detailed instructions for their device are given in other articles on our website.

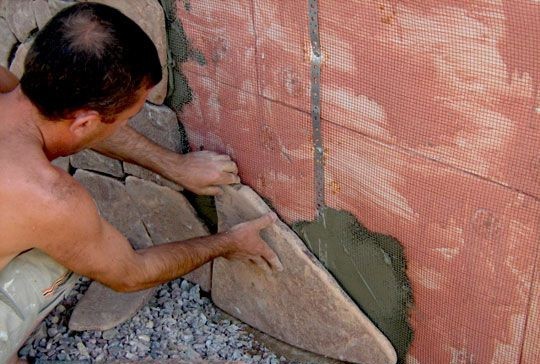

The so-called “wet” method consists in gluing the stone directly to the walls using cement mortar or special glue. They are lining stone buildings, brick, panel or block, not requiring additional insulation.

The use of cement mortar reduces the cost of installation, but makes it more time-consuming, and the lining itself is less reliable. Under the influence of atmospheric phenomena, freezing and thawing cycles, a stone may fall off over time.

Special facade glue is quite expensive, but due to special additives that improve its moisture-resistant properties, it provides reliable adhesion of the cladding to the surface and also simplifies installation.

Conclusion

The beautiful, rich, pleasing look exterior of the house is very important. Facade decoration without any doubt indicates not only solvency, but also the solidity and lifestyle of the owners.

But more importantly, it is practical and durable. And in this regard, it is difficult to find a better material than natural or artificial stone.

The video posted on this page will tell you more about how to choose it and finish it. We will advise you not to save on work, and invite really competent specialists with a good reputation to complete the installation.