Linoleum commercial, semi-commercial, household: their differences and which one to choose

Have you ever read in the product description or heard from a consultant "type of linoleum semi-commercial" when choosing flooring? Or maybe you met a different type and wondered how they differ from each other.

Both natural and synthetic linoleums by scope of application are divided into domestic, semi-commercial, commercial and specialized. Differences are not immediately apparent, because the thickness of commercial linoleum can be the same as that of a specialized one, and it will last a dozen years less.

Based on the type names, some buyers come to the conclusion that household is applicable only at home. And linoleum is commercial, for example, only in the office. But this is not so. This division of flooring is conditional and based only on the level of loads that linoleum can withstand without compromising the appearance and performance according to the manufacturer. Therefore, the owners buy a semi-commercial linoleum for the house if they have heavy furniture or guests often come. Another thing is that using linoleum, classified by classification in another area, is sometimes irrational.

In order to make the right choice, we suggest working out together what this popular coating is, whether the linoleum is regulated by commercial GOST or other standards, which is suitable for an apartment - semi-commercial or household, what is the specific laying of commercial linoleum.

The content of the article

A bit of linoleum history

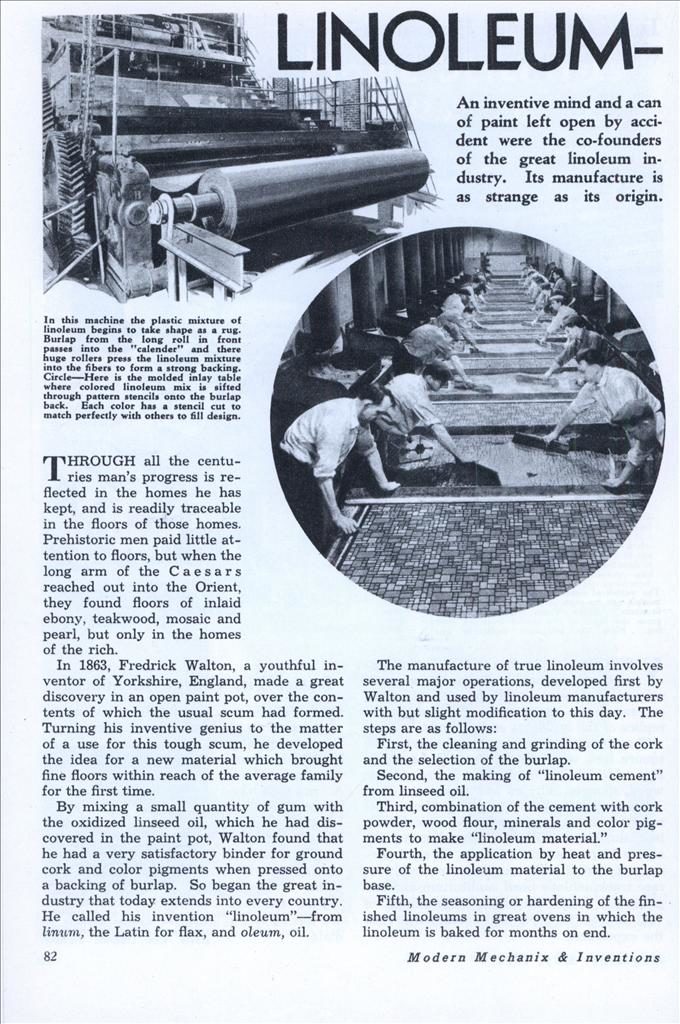

The Vikings used oil-soaked linen for sails several centuries ago. In Europe, oilcloth, aka “oiled canvas”, was patented in 1627 and was used for the same sails on ships and as protective coatings and covers. A prototype of modern linoleum was received by a native of Britain, Nathan Smith in 1763, finalizing the recipe for oilcloths of the last century. In addition to the mixture applied to the fabric hot, he added in addition to linseed oil gum, beeswax and natural brown dye.

The next improvement in composition happened in 1843, when ground cork was first added to the mixture. After some time, rubber became the new ingredient, giving the material elasticity and the corresponding name camptulikon (from the Greek. “Bend”). But soon rubber was needed for a new invention - car tires - and soared sharply. Camptulicon production lost profitability and paused.

Another iconic name in the history of coverage is also English - Frederick Walton released the first material called linoleum (from lat. "Linseed oil"). In addition to the component that gave the name, the composition included resin, chalk, cork and wood flour. The jute fabric was coated with this mixture, and after several weeks of drying, the coating was ready for use.

In 1864, the first factory producing linoleum, Walton, Taylor and Co., began operating in a London suburb. And in 1882, 3 factories were launched near the German city of Bremen. After 20 years, Walton’s company will offer customers glyptal linoleum, a distinctive feature of which is a mixture of several modified vegetable oils in the base. By this time, material will begin to produce in tsarist Russia.

When experiments with the composition were completed and the technology worked out, it was time to improve the appearance of the coating. Manufacturers received new colors, attracted famous artists to design decisions, creating patterns and drawings. Before the war, this industry flourished, and even stayed afloat for a dozen years after recovery at its end. But already in the 60s, the production of natural linoleum entered a longer period of decline - the use of polyvinyl chloride simplified and cheapened the process of creating flooring and displaced it from the market for 20 years. Although linseed oil was not present in the polymeric material from PVC, it was also called linoleum for its external resemblance to its predecessor. When in the 80s natural linoleum returned to the market, it was already positioned as a premium coating for those who can afford environmentally friendly products. Large brands such as Forbo, Grabo and Tarkett abroad and Komitex LIN in Russia offer it today, some under the alternative name of marmoleum.

And, of course, the development of industrial production of synthetic coatings, called artificial linoleum, continues.

Types of linoleum and their differences

Types of linoleum are much more than 4. There are classifications of linoleum for each characteristic of the material (structure, naturalness, thickness, wear resistance, abrasion and fire hazard). But each classification is a topic for a separate article, therefore, in this article we will dwell on the differences between the types of linoleum classified by the field of application and the subspecies of commercial linoleum - homogeneous and heterogeneous. And also consider what specialized linoleum is found on the market.

Domestic

The linoleum recommended for residential use is marked with marks 21, 22 or 23 on the back of the roll and packaging. The number 2 means the household sphere, and the larger the second number, the higher the wear resistance of the sample. The weight of a square meter is from 1.2 to 1.8 kilograms.

The structure of household linoleum is as follows. The lower layer is made of foamed polyvinyl chloride; its function is heat and sound insulation. The intermediate layer contains a pattern or pattern, and the upper layer with a thickness of 0.15-0.3 mm protects the coating from abrasion.

A high-quality household coating will not suffer from moisture, will not accumulate dust, and the pattern will not fade over time. It’s easy to clean such linoleum, and there will be no problems with installation - the hosts easily roll out this rolled material and fix it with their own hands. There are even performance indicators in which the coating for a living room exceeds commercial grade linoleum - heat and sound absorption, as well as orthopedics (stiffness). An advantage is the affordable price. But the indicators of wear resistance and abrasion are the lowest in the line, because a stepped heel or a dropped fork will cause irreparable damage. On average, household linoleum is laid for 5-7 years, a longer service without damage will most likely be the exception to the rule.

It is not recommended to equip premises with high traffic, such as a kitchen, living room and hallway with the help of household linoleum. But the cover is suitable for the bedroom and home office.

Semi-commercial

Semi-commercial linoleum, marked by the manufacturer with a number from 31 to 34, combines the best properties of household and commercial: this is a kind of compromise between them. With the first it is similar to ease of laying and ease of handling, and with the second - resistance to wear and damage. The price for semi-commercial coverage also lies somewhere in the middle.

Manufacturers recommend laying such linoleum in rooms that do not directly communicate with the street, with average traffic. Examples of such places are hotel rooms, office rooms, wards in hospitals.In the apartment, semi-commercial linoleum is appropriate in the corridor, hallway, living room and kitchen.

The weight per square meter of such a coating is more than that of a household one, it varies from 2 to 2.5 kilograms, but the structure is practically the same. The layers are the same, only additionally reinforced with fastening fiberglass, and the thickness of the protective layer is up to 2 times greater, reaching 0.6 mm. Thanks to fiberglass in the composition, the skeleton (consistency density) of semi-commercial linoleum is also higher compared to household. These factors make the coating resistant to stress and damage.

Commercial heterogeneous and homogeneous

The requirements for flooring are best met by commercial linoleum. It is a leader in terms of strength, durability, abrasion, fire hazard, and also with the greatest success resists common and point loads, moisture, ultraviolet radiation and chemical reagents. Markings with numbers from 41 to 43 correspond to it. Only commercial linoleum can withstand temperatures from -40 to +50 Celsius (for comparison, comfortable temperature for household and semi-commercial coatings from -10 to +40 degrees), as well as only this type of linoleum among synthetic samples will last up to 25 years. There is only one serious drawback for such material - the cost that exceeds the capabilities of most buyers. But, if you look, in the everyday life of the average apartment there are no such loads when commercial linoleum would fully show its properties.

The commercial coating reinforced with polyurethane is used in rooms visited not by dozens, but by thousands of people per day, as well as units of equipment and technology. These include a factory, factory, wholesale warehouse, university, clinic. As well as the airport, train station, shopping and entertainment center, government agencies.

Commercial linoleum production in the Russian Federation is regulated by GOST 11529-86. Such a mark on the packaging indicates that the material complies with the state standard and its technical characteristics will not be lower than declared.

There are 2 types of commercial linoleum, depending on the structure: homogeneous and heterogeneous (which is also found in household and semi-commercial, in contrast to the first type).

Homogeneous linoleum is characterized by extreme wear resistance. It is made by adding chalk, lime and other additives to PVC. The material is thin (no thicker than 3 mm), homogeneous, has no basis, is a single layer, soaked through with paint.

In a heterogeneous coating, the pattern is applied only to the intermediate layer of the decor. This layer with a pattern is applied to the base of foamed polyvinyl chloride or natural materials - jute or felt. And the top layer of heterogeneous linoleum is protective (it is also working). Made from compressed granules of polyvinyl chloride. The layers are fastened with fiberglass, as a result, a thickness of up to 6 mm is achieved. The more expensive the coating, the higher the likelihood that additional layers are added there, enhancing the positive properties of linoleum. In the line of heterogeneous linoleums, a wider variety of patterns and colors is offered, and additives that make the coating specialized can only be added to it.

Specialized

Specialized commercial linoleum is also called such a floor covering, in which one of the operational properties is significantly enhanced, some of the characteristics is key. For example, acoustic linoleum has enhanced noise isolation function, the ability to absorb sound up to 19 dB. Regular customers of such rolls on a foam basis, thanks to which no steps are heard, are hospitals and libraries.Anti-slip and sports linoleum have similar characteristics, and both are designed to ensure safety. Only in gyms and fitness clubs, slip resistance is increased by adding corundum chips to the composition, and in rooms with high humidity, coatings with a corrugated surface are more often used. Models with increased antistaticity are additionally divided into conductive and current-dispersing ones and are designed to divert static electricity from the room, which accumulates from the devices used there. The resistance force of conductive linoleum is about 105 Ohms (+ -1), current-scattering - reaches 108 Ohms. The final charge of both coatings is no more than 2 kV, which is achieved by interspersing graphite filaments in the material.

They cover the area with a large number of units of office equipment and equipment with an antistatic coating: school computer classes for computer science lessons, research laboratories and x-ray rooms in hospitals. Indispensable in workshops for the production of explosives, electrical appliances and their individual elements. During installation, they use special conductive glue and a special mesh that displays current.

Separate groups are linoleums for transport and medical institutions. Transport linoleum is used in railroad cars and subway trains, buses and trolleybuses, and aircraft cabins. In addition to durability, fire resistance, waterproofness and low toxicity, it is characterized by anti-slip effect. Adhesion is enhanced by the addition of carborundum to the composition. For medical institutions, the hygiene of the coating plays a paramount role, therefore, components that prevent the survival and reproduction of bacteria and fungi are added to such a specialized linoleum.

Which to choose

The choice of linoleum does not begin with the question “what?”, But with the question “where?”. Depending on where it is planned to lay linoleum, from the analysis of the room, potential loads, the desired additional properties and choose a coating. In the apartment you can lay an inexpensive household linoleum, if there are few inhabitants and guests, and the floor loads are insignificant. A semi-commercial linoleum is better for a house where a large family lives and often receive guests. Moreover, even if in the remaining rooms it was decided to lay synthetic linoleum, then for the children's room it is worth choosing natural samples.

It makes no sense to lay commercial linoleum in an apartment, since there are no loads for which it is designed and excess expenses will not be justified. But for enterprises and institutions, such coverage will be indispensable. Especially if you choose a specialized linoleum with enhanced properties that are most valuable for a particular room, based on the specifics of the activities carried out in it.

Pay attention to trusted manufacturers who have long established themselves in the market, but these are not necessarily foreign companies. In Russia, there are also large manufacturers of linoleum, which offer high-quality products that can compete with foreign companies. At the same time, the price of Russian linoleum is more democratic and attractive.

Do not hesitate to ask the seller for a quality certificate and make sure that this sample is not a fake.

Linoleum: their differences and which one to choose: Video